Table of Contents

Togglehe Intelligent Hub of Electrical Automation Manufacturing: Technological Evolution and Industrial Innovation of Contactor Assembly Machines - RUI ZHI

I. The Industrial Revolution of Contactor Assembly: From Manual Era to Intelligent Age

In the field of industrial control and power electronics, contactors, as core components for circuit on-off control, have their assembly precision directly determining the reliability and safety of equipment. Traditional manual assembly models suffer from three core pain points: low efficiency (45-70 seconds per piece), fluctuating precision (±0.3mm alignment error of contacts), and high labor costs (accounting for 25%-35% of production costs). Contactor assembly machines have achieved a revolutionary leap from “manual assembly” to “full-process automation” by integrating multi-axis robotic arms, visual inspection, and intelligent control systems.

Take a Zhejiang-based electrical group as an example: after introducing the third-generation intelligent contactor assembly line, the daily capacity of a single line increased from 3,000 units to 12,000 units, labor demand was reduced from 18 to 3 workers, while the consistency of contact resistance improved by 92%, and the failure rate in withstand voltage tests dropped from 1.8% to 0.05%. This transformation not only manifests in capacity improvement but also realizes full-process traceability of key parameters through real-time quality monitoring—for instance, after a automotive relay factory adopted laser welding for contacts, the standard deviation of welding strength was optimized from ±8N to ±1.2N, meeting the strict standards of ISO 9001:2015.

II. Technical Architecture Analysis: A Four-Dimensional Intelligent Assembly Ecosystem

The technological advancement of contactor assembly machines stems from the collaborative design of four core modules, constructing a closed-loop ecosystem from component supply to finished product inspection:

1. High-Speed Precision Feeding System

As the starting point of the assembly process, the feeding system must achieve precise supply of multi-type components:

- Vibratory Bowl + Visual Sorting: Using 3D structured light cameras to identify special-shaped parts such as contacts, coils, and arc extinguishers, and distinguishing 0.1mm-level dimensional differences through AI algorithms, with a sorting efficiency of 120 pieces/minute and a misfeeding rate <0.01%.

- Flexible Feeding Solution: For thin-sheet parts (such as silver alloy contacts), electromagnetic vibration plates combined with negative pressure adsorption technology are adopted to avoid deformation damage caused by traditional mechanical claws, increasing part yield to 99.7%.

2. Multi-Axis Linkage Assembly Unit

The assembly execution layer integrates robotic technology with precision mechanical design:

- Six-Axis Servo Robotic Arm: Such as Yaskawa Motoman GP25, with repeat positioning accuracy of ±0.02mm, capable of completing complex actions like coil winding and contact riveting, achieving precise alignment with a 0.1mm gap in the assembly of a high-voltage contactor.

- Dedicated Tooling Quick-Change System: Through pneumatic locking mechanisms, it supports 8-minute rapid switching of tooling modules for AC and DC contactors, adapting to the production of 09-95A full-series products.

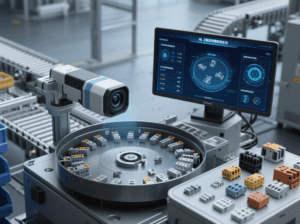

3. Visual Inspection and Quality Closed Loop

A multi-level inspection system is adopted to achieve full-process quality control:

- Micron-Level Visual Positioning: Equipped with 10K industrial cameras and laser displacement sensors, it performs ±0.03mm-level pose compensation before contact welding, ensuring the uniformity deviation of contact pressure <5%.

- Functional On-Line Testing: Integrating withstand voltage testers (2000V/10mA) and contact resistance meters (100mΩ range), each contactor undergoes 12 electrical performance tests, with data uploaded to the MES system in real time for full-life cycle traceability.

4. Intelligent Control System Architecture

As the “nerve center” of the equipment, the control system realizes multi-dimensional collaboration:

- PLC + Industrial PC Dual Architecture: Using Beckhoff CX5140 controller with a scanning cycle <1ms, supporting synchronous control of 200+ IO points to meet the real-time scheduling of complex contactor action sequences.

- Digital Twin Optimization: Through virtual simulation, assembly paths are verified in advance. After application in a railway contactor production line, idle travel time was reduced by 40%, and the assembly cycle per unit was compressed from 28 seconds to 16 seconds.

III. Industry Application Scenarios: Universal Coverage from Low-Voltage Electrical Appliances to High-End Equipment

Contactor assembly machines have deeply penetrated the core fields of electrical manufacturing due to their flexibility and high precision:

1. New Energy Vehicle Electric Drive Systems

- Case: A leading new energy vehicle manufacturer introduced a customized contactor assembly line to achieve fully automatic assembly of high-voltage contactors (1000V/300A) for on-board DC/DC converters. The qualified rate of withstand voltage tests increased from 89% in manual assembly to 99.97%, meeting the safety standards of ISO 6469-3 for electric vehicles.

- Technical Highlights: Integrated vacuum potting module, using automatic epoxy resin filling technology to ensure the airtightness of the arc extinguishing chamber reaches 10^-5Pa·m³/s, adapting to the vibration and temperature shock requirements of vehicle environments.

2. Smart Home and Building Automation

- Case: A smart home manufacturer adopted a modular assembly machine to support mixed-line production of contactors for 8 specifications of smart home controllers, with a changeover time of only 12 minutes, meeting the market demand for small batches and multiple varieties, and reducing production costs by 35%.

- Technical Highlights: Equipped with an RFID component tracing system, realizing full-process data binding from coil winding to finished product packaging, supporting rapid positioning of after-sales faults.

3. Industrial Automation and Power Systems

- Case: A switchgear factory of State Grid introduced a high-voltage contactor intelligent production line to achieve automated assembly of 35kV-level contactors, improving contact pressure consistency to ±3%, meeting the requirements of GB 14048.4-2010 standards, and increasing production efficiency by 5 times.

- Technical Highlights: Adopting helium mass spectrometry leak detection technology to perform 10^-9Pa·m³/s-level leak detection on sealed arc extinguishing chambers, ensuring arc extinguishing performance in high-voltage environments.

IV. Future Technical Trends: Deep Integration of AI Empowerment and Green Manufacturing

Driven by Industry 4.0 and carbon neutrality goals, contactor assembly technology is evolving in three major directions:

1. Deep Integration of Artificial Intelligence

- Adaptive Process Optimization: A deep learning-based process parameter self-adjustment system, such as using CNN to identify solder joint morphology and optimize laser welding power in real time, reducing the standard deviation of silver contact welding strength from ±5% to ±1.8%.

- Predictive Maintenance System: Using vibration sensors and LSTM neural networks to predict robotic arm joint wear, reducing unplanned downtime by 70% and maintenance costs by 40%.

2. Green Manufacturing Technological Innovation

- Energy Consumption Optimization Design: Servo motors adopt regenerative braking technology with an energy recovery efficiency of 75%, reducing annual power consumption per device by 5,200kW·h, equivalent to a 3.2-ton carbon emission reduction.

- Lead-Free Process Application: Promoting laser brazing instead of traditional tin soldering to avoid lead pollution, while increasing solder joint strength by 20%, meeting RoHS 3.0 environmental standards.

3. Digital Twin and Cloud Collaboration

- Virtual Debugging Platform: A digital twin system developed based on Unity that can complete assembly process verification of new models in a virtual environment, shortening the trial production cycle from 45 days to 15 days.

- Cloud Process Library: Establishing a knowledge graph of contactor assembly processes to support global factory process experience sharing. After application by a multinational enterprise, new product introduction efficiency increased by 60%.

V. Implementation Path and Industry Challenges: From Equipment Procurement to Value Realization

When deploying contactor assembly machines, enterprises need to focus on three major implementation dimensions:

1. Process Adaptability Assessment

- Component Tolerance Analysis: For example, the flatness tolerance of contact reeds needs to be controlled within ±0.05mm; otherwise, an online leveling process must be added. An electrical factory reduced later transformation costs by 380,000 RMB through early DFA (Design for Assembly) optimization.

- Capacity Matching Calculation: Taking an annual output of 1 million contactors as an example, 2 high-speed assembly lines (12 seconds/unit cycle) need to be configured, with an investment payback period of approximately 14 months and an annual labor cost saving of 1.2 million RMB.

2. System Integration and Data Interconnection

- Protocol Standardization: It is necessary to ensure seamless docking between the assembly machine and ERP/MES systems, using the OPC UA protocol to achieve real-time upload of production data (such as yield rate, equipment OEE). A listed company shortened the production cycle by 22% through data-driven approaches.

- Safety Compliance Design: Equipped with emergency stop interlocks, light curtain protection, and other safety devices, meeting the ISO 13849 PLd safety level to ensure operational safety in human-robot collaboration scenarios.

3. Talent Echelon Construction

- Composite Technical Team: It is necessary to cultivate engineers with comprehensive capabilities in mechanical design, visual algorithms, and PLC programming. An enterprise shortened the talent cultivation cycle from 12 months to 6 months by cooperating with universities to establish an “Intelligent Assembly Special Class”.

- Remote Operation and Maintenance Capability: Realizing remote debugging and fault diagnosis of equipment through 5G+AR technology, reducing response time from 4 hours to 30 minutes, suitable for globally deployed enterprises.

Conclusion

As core equipment for intelligent electrical manufacturing, contactor assembly machines are reshaping the industry landscape through technological innovation. From household appliances to new energy vehicles, from low-voltage power distribution to high-voltage power systems, their application depth and breadth continue to expand. With the integration of AI vision, digital twin, and green manufacturing technologies, this field will embrace broader development, providing strong support for enterprises to achieve production goals of “high precision, high efficiency, and high reliability”. In the future, how to find a balance between flexible production and economies of scale, and how to build an open technical system through ecological cooperation, will become key propositions for continuous industry innovation.

#contactor component #contactor assembly machine #Automation equipment