The Long-Standing Challenge: Printing on Curved, Grooved, or Irregular Surfaces

In manufacturing and design, printing on non-flat surfaces—such as a guitar body with smooth contours, an ergonomically ridged tool handle, or a decoratively curved vase—has long been a stubborn hurdle. Historically, these surfaces required painstaking manual work or expensive, specialized machinery, often forcing a trade-off between precision and flexibility.

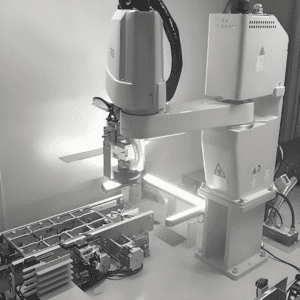

Epson’s DTO System: A European Debut Merging Robotic Precision and Inkjet Innovation

This week at Germany’s Automatica trade fair, Epson is set to rewrite this narrative with the European launch of its groundbreaking direct-to-shape (DTO) printing system. A fusion of robotic precision and advanced inkjet technology, it promises to revolutionize how 3D objects are decorated and labeled.

More than just a printer, it’s a marriage of Epson’s core strengths: industrial robotics and inkjet innovation. For the first time outside Japan, attendees will witness a six-axis industrial robot equipped with Epson’s compact yet powerful S800 PrecisionCore inkjet printheads, “dancing” around complex shapes to deliver crisp, vibrant designs with the accuracy once reserved for flat surfaces. It offers a glimpse of a future where customization, speed, and precision coexist—even on the most irregular forms.

- A Symphony of Robotics and Inkjet Tech: The Core of the DTO System

At the heart of Epson’s new DTO system lies a clever pairing: the company’s six-axis industrial robot (renowned for pinpoint movement control) and the S800 PrecisionCore printhead—the smallest in Epson’s micro piezo lineup. This compact printhead (just 33.8mm in print width) is a miniaturization marvel, packing the precision to handle intricate details without being hindered by the object’s curves.

What truly sets the system apart is its “precision trajectory control” and advanced image processing. As the robot maneuvers around a 3D object (e.g., a rounded guitar body), the system adjusts dynamically: sensors map the object’s contours in real time, while five independent printheads (each movable up or down individually) “hug” the surface. This ensures ink lands exactly where intended—even on grooves or angled edges—like a painter with an infinitely steady hand, following every twist of the canvas.

- Performance That Speaks for Itself: Quality, Versatility, and Engineering Prowess

In terms of quality, the DTO system does not compromise. It delivers 600x600dpi resolution—sharp enough for detailed logos, text, or even photorealistic designs. Color options are equally versatile: supporting CMYK plus white as standard, with customization for specialized needs like metallic or UV-curable inks. This flexibility opens doors for industries ranging from musical instrument manufacturing (custom guitar finishes) to automotive (branding on curved dashboard components) and consumer goods (personalized tool handles or cosmetic containers).

Epson’s engineers spent years refining the system at the company’s Inkjet Innovation Lab in Nagano Prefecture, focusing on 3D printing’s unique challenges. “Flat surfaces are straightforward—you move the printhead in a straight line,” explains a lead developer. “But with curves, every millisecond counts. The robot must anticipate the object’s shape, adjust the printhead height, and fire ink at exactly the right moment. It’s a ballet of mechanics and software.”

- From Trade Fair Debut to Real-World Impact: Deployment and Collaboration Plans

Automatica—Europe’s premier showcase for intelligent automation—is the perfect stage for this debut. Running June 24-27 in Munich, the fair draws industry leaders eager to explore cutting-edge robotics, and Epson’s DTO system aligns with its key themes: industrial robotics, image processing, and software integration.

The showcase is just the first step. Post-fair, the system will move to Epson’s Düsseldorf facility (Germany), serving as a customer test bed. Brands can bring their own substrates—curved plastic parts or custom metal components—and collaborate with Epson to fine-tune printing processes, accelerating real-world adoption. Epson is also seeking partnerships to commercialize the system, aiming to make it accessible to manufacturers of all sizes.

- A New Era for Customization: Meeting Demand for Personalized Products

In a world craving personalization, Epson’s DTO system arrives at a critical moment. Consumers want products reflecting their tastes—from one-of-a-kind guitar graphics to name-printed water bottles. Manufacturers, meanwhile, need efficient, cost-effective ways to meet this demand without slowing production.

Epson’s solution checks both boxes. By automating the once-laborious 3D surface printing process, it slashes production time while unlocking new creative possibilities. “This isn’t just about making things look better,” says an Epson robotics division executive. “It’s about giving designers and manufacturers the freedom to imagine shapes and surfaces they couldn’t before—because they know printing on them will be easy.”

As first visitors gather around Epson’s booth at Automatica, they’ll see more than a robot and printhead. They’ll see manufacturing’s future: where technology bends to the real world’s complexity, not the other way around. For Epson, this debut is more than a product launch—it’s a statement: when robotics and inkjet innovation join forces, even the most curved, grooved, or irregular surfaces become canvases waiting to be transformed.

Application cases of Epson robots in Industry 4.0

How about Epson robots’ after-sales service?