Generative Artificial Intelligence (GenAI) provides a higher level of intelligent support for digital twins by learning historical data and real-time information. It not only improves the prediction and analysis capabilities of digital twins but also endows the system with the characteristics of self-learning, self-optimization, and self-adaptation.

In modern manufacturing, Cyber-Physical Production Systems (CPPS) are gradually becoming the core of smart factories. CPPS seamlessly integrates computational intelligence with physical processes to form a dynamic and interconnected industrial ecosystem, enabling real-time communication and collaboration between machines, sensors, and human operators. This integration not only improves production efficiency but also paves the way for the intelligent transformation of the manufacturing industry.

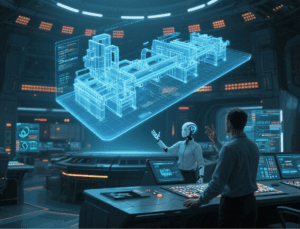

Digital Twin: A Real-Time Mirror of the Physical World

A Digital Twin is a real-time virtual copy of a physical asset, continuously updated through sensors or other data sources to accurately reflect the state and performance of its physical counterpart. It is not just a static 3D model but a dynamic, interactive, and predictive digital system.

In industrial production, digital twins can be used for:

Monitoring: Real-time tracking of the operating status of equipment, production lines, and logistics systems

Optimization: Simulating different production scenarios to optimize processes and resource allocation

Decision-making: Testing solutions in a virtual environment to reduce the risk of trial and error in reality

Three Core Values of Digital Twins in CPPS

- Real-Time Monitoring and Predictive Insights

Enabling equipment health monitoring, early anomaly detection, and predictive maintenance to reduce unplanned downtime.

- Process Optimization and Efficiency Improvement

Simulating various production scenarios to identify bottlenecks, optimize processes, and improve resource utilization. For example, in the Automatic Injection – Molded Part Feeding And Assembly process, digital twins can accurately map the part conveying trajectory, assembly precision, and equipment collaboration status. Through virtual simulation, potential issues such as unbalanced feeding rhythm and component alignment deviation can be detected in advance, thereby optimizing the feeding path and assembly sequence, and significantly reducing the jamming rate and assembly errors in actual production.

- Enhanced Decision-Making and Risk Reduction

Verifying modification plans in a virtual environment first to ensure that decisions are based on data and predictive analysis, reducing potential risks.

- Generative Artificial Intelligence (GenAI): The Intelligent Engine of Digital Twins

Generative Artificial Intelligence (GenAI) provides a higher level of intelligent support for digital twins by learning historical data and real-time information. It not only improves the prediction and analysis capabilities of digital twins but also endows the system with the characteristics of self-learning, self-optimization, and self-adaptation.

Key Capabilities of GenAI Empowering Digital Twins

- Autonomous Optimization and Self-Learning

Using big data analysis and pattern recognition to automatically propose process improvement suggestions, reducing manual intervention.

- Next-Generation Predictive Maintenance

Simulating potential failure scenarios to develop optimal maintenance plans, reducing downtime and maintenance costs.

- Adaptive and Flexible Manufacturing

Automatically adjusting production parameters based on real-time data to quickly respond to changes in market demand.

- Synthetic Data Generation and AI Training

Creating high-fidelity synthetic datasets for training machine learning models, reducing reliance on expensive and time-consuming real-world experiments, and driving innovation.

Digital Twin + GenAI: Building Resilient Manufacturing for Industry 5.0

When digital twins are combined with generative artificial intelligence, manufacturing enterprises can build a highly automated, flexible, and sustainable production system:

Balancing efficiency and resilience: The system can quickly self-adjust in the face of emergencies, demand changes, or supply chain disruptions.

Improving cost and sustainability: Predictive analysis and automation reduce energy consumption, raw material waste, and maintenance costs.

Enhancing competitiveness: Enterprises that take the lead in adopting this technology will gain an advantage in global manufacturing competition.

This integrated technology is not only a continuation of Industry 4.0 but also an important fulcrum for moving towards Industry 5.0 — a new era where human-machine collaboration is closer, manufacturing is more personalized, and large-scale production efficiency is maintained.

Conclusion

Digital twins provide a digital mapping of the real world for industrial systems, while generative artificial intelligence endows this “mirror” with the ability to think and predict. The combination of the two not only reshapes the operation mode of the manufacturing industry but also outlines a more flexible, intelligent, and sustainable development blueprint for future industrial automation.

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot