Table of Contents

ToggleA New Benchmark in Medical Manufacturing: Technological Breakthroughs and Industrial Innovation of Nebulizer Assembly Machines

I. The Industrial Revolution of Nebulizer Assembly: From Manual Crafting to Intelligent Clean Production

In the global wave of medical device intelligent transformation, nebulizers, as core instruments for respiratory disease treatment, rely on assembly precision to directly affect drug delivery efficiency and patient safety. Traditional manual assembly models suffer from critical pain points: low efficiency (50-80 seconds per piece), fluctuating precision (±0.1mm error in nozzle aperture), and cleanliness risks (manual operation contamination rate ~1.2%). Nebulizer assembly machines have achieved a leap from “handcrafted assembly” to “intelligent clean production” by integrating precision mechanical transmission, visual inspection, and aseptic control technologies.

Take a Shenzhen-based medical device enterprise as an example: after introducing the third-generation intelligent nebulizer assembly line, daily capacity per line surged from 2,000 to 8,000 units, labor costs dropped by 70%, and the qualification rate for key component sealing increased from 88% to 99.7%. This transformation not only reflects efficiency gains but also controls the fluctuation range of nebulized particle median diameter (MMAD) within ±0.05μm through a full-process quality traceability system, meeting the strict requirements of the ISO 13485 medical device quality management system.

II. Technical Architecture Analysis: A Four-Dimensional Precision Manufacturing Ecosystem

The technological advancement of nebulizer assembly machines stems from the deep integration of four core modules, constructing a full closed-loop ecosystem from component supply to finished product inspection:

1. Precision Flexible Feeding System

As the starting point of the assembly process, the feeding system ensures precise positioning of multi-form components:

- Vibratory Bowl + Visual Sorting: Using 3D laser scanning and AI image recognition technology, micron-level dimension detection is performed on special-shaped parts like nebulizer nozzles and drug reservoirs, with a sorting efficiency of 100 pieces/minute and a misfeeding rate <0.005%.

- Negative Pressure Adsorption Conveyance: For thin-walled plastic parts (e.g., nebulizer cups), customized vacuum suction cups and flexible fixtures prevent stress deformation caused by traditional mechanical claws, increasing part yield to 99.9%.

2. Multi-Axis Linkage Assembly Unit

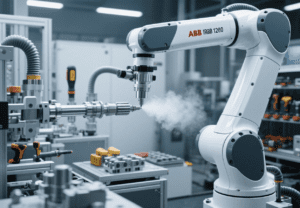

The assembly execution layer integrates high-precision robotic arms and specialized tooling:

- Six-Axis Servo Manipulator: Such as ABB IRB 1200, with repeat positioning accuracy of ±0.01mm, capable of achieving 0.2mm-gap precise docking of nozzles and pipelines, enabling 12 high-speed assemblies per minute in an ultrasonic nebulizer production line.

- Modular Quick-Change System: Through pneumatic plug-in mechanisms, it supports rapid switching between three 主流 (ultrasonic, mesh, and compressed air) nebulizer models, reducing changeover time to 10 minutes to meet small-batch, multi-variety production needs.

3. Visual Inspection and Quality Closed Loop

A multi-level inspection system ensures product quality throughout the lifecycle:

- Micron-Level Dimension Measurement: Equipped with 20MP industrial cameras and laser micrometers, online inspection of nebulizer mesh pore diameters (typical value 3-5μm) is performed, with 100% automatic rejection of out-of-tolerance parts.

- Functional Intelligent Testing: Integrates flow sensors and pressure testers to simulate patient usage environments for 8 performance tests (e.g., spray rate 0.2-0.5ml/min, particle size distribution MMAD 3-5μm), with data uploaded to the MES system in real time.

4. Clean Production Control System

As the core guarantee for medical device manufacturing, the system strictly adheres to GMP standards:

- Laminar Flow Purification Design: Equipped with Class 100 clean workbenches, FFU fan filter units, and dynamic particle monitoring systems, ensuring suspended particle concentration in the assembly environment ≤3.5 particles/m³.

- Aseptic Treatment Module: Implements online UV sterilization (wavelength 254nm, irradiation intensity ≥4000μW·s/cm²) for key components, combined with an EO sterilization traceability system to achieve full-process aseptic control.

III. Industry Application Scenarios: Universal Coverage from Home Care to Clinical Medicine

Nebulizer assembly machines have deeply penetrated all fields of healthcare due to their high precision and cleanliness:

1. Home Medical Device Market

- Case: A multinational pharmaceutical company introduced a customized assembly line to automate production of pediatric nebulizers, with a single device producing 5,000 units daily. A color recognition system ensures 100% accuracy of age-specific labels, meeting CE and FDA dual certification requirements.

- Technical Highlights: Integrated voice prompt modules provide real-time alerts for operational anomalies during assembly, reducing manual verification time by 40%.

2. Clinical Medical Equipment Manufacturing

- Case: A partner enterprise of a top tertiary hospital in China uses an intelligent assembly line to produce ICU-specific nebulizers. Online pressure sensor detection of drug reservoir sealing (leakage rate ≤10⁻⁶ Pa·m³/s) has reduced product defects from 3.2% in manual assembly to 0.15%, complying with YY 0509-2014 medical ultrasonic nebulizer standards.

- Technical Highlights: Configured with an ESD anti-static system to prevent electrostatic damage to electronic components (e.g., ultrasonic transducers) during assembly.

3. Veterinary Medicine Field

- Case: A veterinary medical device manufacturer applied modular assembly machines to achieve mixed-line production of pet-specific nebulizers, supporting rapid switching between cat and dog specifications, shortening production cycles by 60%, and capturing 30% of the niche market share.

- Technical Highlights: Adopts RFID chip implantation for full-life cycle traceability, enhancing brand trust.

IV. Future Technical Trends: Deep Integration of Intelligence and Medical Innovation

Driven by Medical 4.0 and growing demands for personalized treatment, nebulizer assembly technology is evolving in three key directions:

1. AI-Driven Adaptive Production

- Process Parameter Self-Optimization: Based on deep learning algorithms, real-time analysis of 300+ production parameters (e.g., welding temperature, pressure curves) automatically adjusts assembly processes, improving nozzle atomization efficiency consistency by 25%.

- Predictive Maintenance System: Uses vibration sensors and LSTM neural networks to provide advance warnings of robotic arm joint wear, reducing unplanned downtime by 80%.

2. Digital Twin and Virtual Commissioning

- Full-Process Simulation Platform: Builds a digital twin system based on Unity 3D to verify new process feasibility in a virtual environment, shortening new product R&D cycles from 90 to 35 days.

- Cloud-Based Process Sharing: Establishes a nebulizer assembly process knowledge base to support global factory technical collaboration, improving new product introduction efficiency by 70% for a multinational enterprise.

3. Green Manufacturing and Sustainable Development

- Energy Consumption Optimization Design: Servo motors adopt energy recovery technology, saving 6,500kW·h annually per device, equivalent to a 5.2-ton carbon emission reduction.

- Biodegradable Material Adaptation: Develops special assembly modules for PLA biobased plastics to support mass production of degradable nebulizers, responding to EU green medical initiatives.

V. Implementation Path and Industry Challenges: From Equipment Deployment to Value Realization

Enterprises introducing nebulizer assembly machines should focus on three key implementation dimensions:

1. Process Adaptability Assessment

- Material Compatibility Testing: For medical-grade plastics like PCTG and PP, verify hot-press welding parameters (temperature 220-240℃, pressure 0.3-0.5MPa). One enterprise reduced welding defects from 8% to 1.5% through pre-deployment DOE experiments.

- Capacity Planning Model: For an annual output of 1 million units, configure 3 high-speed assembly lines (18-second cycle per unit), with an investment payback period of ~16 months and annual labor cost savings of 9 million RMB.

2. System Integration and Compliance Certification

- Data Interconnectivity: Uses OPC UA protocol for seamless docking between assembly machines and ERP/LIMS systems, with real-time production data uploads supporting FDA 21 CFR Part 11 electronic signature requirements.

- Regulatory Certification Support: Equipment includes built-in CE/ISO 13485 compliance check modules that automatically generate validation documents, helping enterprises shorten certification cycles by 50%.

3. Professional Talent Echelon Construction

- Composite Technical Team: Cultivates engineers with expertise in medical device regulations, machine vision algorithms, and cleanroom engineering. One enterprise shortened talent development cycles to 8 months through university-enterprise joint training.

- Remote Operation Capability: Leverages 5G+AR technology for remote equipment debugging and fault diagnosis, reducing response time from 4 hours to 20 minutes to ensure continuous production.

Conclusion

As core equipment for intelligent medical manufacturing, nebulizer assembly machines are reshaping industry landscapes through technological innovation. From home health care to clinical critical care, their application scenarios continue to expand. With the deep integration of AI, digital twin, and green technologies, this field will provide stronger manufacturing support for precision medicine and personalized treatment. In the future, balancing compliance and innovation while promoting medical manufacturing upgrades through ecological collaboration will become a key proposition for sustainable industry development.

#High-Efficiency Automatic Assembly Machine #Put together the nebulizer machine #Intelligent automation