In industrial production, the stable operation of equipment is crucial, and the rational setting of maintenance cycles is key to ensuring the normal operation of equipment. So, what exactly is the scientific basis for setting equipment maintenance cycles? This issue is equally indispensable in the field of CNC (Computer Numerical Control) machining—especially in CNC precision machining and precision parts machining.

Equipment Working Principles and Wear Laws

Different types of equipment have distinct working principles, which directly affect the setting of maintenance cycles. Take a CNC machining center as an example: during its operation, key components such as the spindle, lead screw, and guide rail are in a state of high-speed movement and continuously rub against each other. For automatic buckle feeding and assembly equipment—commonly used in automotive interiors, electronic product assembly lines—its core components like feeding rails, positioning pins, and buckle clamping jaws undergo repeated friction and impact during high-frequency continuous operation. According to the principles of mechanical kinematics and tribology, these components will inevitably experience wear after long-term operation. Studies have shown that in the early stage of equipment operation, the wear rate of parts is relatively slow, a phase known as the initial wear stage. As operating time increases, the wear rate accelerates, entering the normal wear stage. When wear reaches a certain level, it progresses to the severe wear stage, where equipment performance declines sharply (e.g., buckle feeding jams, assembly misalignment) and failures may even occur. Based on this wear law, equipment maintenance cycles should be reasonably scheduled within the normal wear stage. Regular inspection, lubrication, and replacement of key components—such as cleaning feeding rails and calibrating positioning pins for automatic buckle feeding and assembly equipment—are essential to prevent the equipment from entering the severe wear stage.

Operating Environment Factors

The operating environment of equipment has a significant impact on maintenance cycles. Equipment operating in harsh environments—such as high temperature, high humidity, or heavy dust—is more susceptible to component corrosion, oxidation, and contamination. For instance, in a foundry workshop, high temperatures and dust accelerate equipment aging and wear, requiring more frequent maintenance. In contrast, in a CNC precision machining workshop with constant temperature, constant humidity, and cleanliness, the equipment’s operating environment is relatively favorable, allowing for appropriate extension of maintenance cycles. Additionally, if equipment operates under long-term high load, internal components bear greater pressure and heat, intensifying wear. For example, automatic buckle feeding and assembly equipment running 24/7 in large-scale automotive assembly plants will have accelerated wear of its transmission gears and clamping mechanisms, so maintenance cycles need to be shortened accordingly.

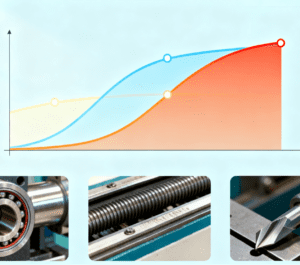

Cumulative Operating Hours Statistics

The cumulative operating hours of equipment is one of the important bases for setting maintenance cycles. Through statistical analysis of operating hours, the wear degree and service life of equipment components can be roughly estimated. For example, according to the manufacturer’s technical data and extensive practical usage records, the spindle of a specific model of CNC machining center will experience a certain level of wear on its bearings and tool chucks after 5,000 hours of operation, which affects machining accuracy. For automatic buckle feeding and assembly equipment, data shows that its feeding rail wear will lead to unstable buckle conveying after 6,000 hours of continuous operation, and positioning pin accuracy drift will cause assembly deviation. Therefore, when the equipment’s operating time approaches 6,000 hours, targeted maintenance should be scheduled to grind and maintain feeding rails and replace worn positioning pins, ensuring the precision and efficiency of buckle assembly.

Fault Data Analysis

Analyzing historical fault data of equipment also provides a scientific reference for setting maintenance cycles. By collecting and organizing information such as fault types, occurrence times, and causes of equipment failures, the weak links and high-fault periods of the equipment can be identified. If a specific component of a piece of equipment frequently fails after a certain period of operation, the maintenance cycle for that component should be shortened, and enhanced inspection and maintenance should be implemented to prevent recurring failures. For example, if automatic buckle feeding and assembly equipment frequently encounters clamping jaw sticking due to insufficient lubrication, the maintenance cycle for lubrication checks should be shortened from 3 months to 1.5 months, with regular grease replenishment and wear detection to avoid production line interruptions.

The setting of equipment maintenance cycles is not arbitrary; it is based on multiple scientific foundations, including equipment working principles and wear laws, operating environment, cumulative operating hours statistics, and fault data analysis. This applies equally to specialized equipment such as automatic buckle feeding and assembly equipment in precision assembly scenarios. In practical production, enterprises should comprehensively consider these factors and develop personalized maintenance cycles for different equipment. This ensures equipment remains in good operating condition, improves production efficiency, and guarantees the smooth progress of work such as CNC machining, CNC precision machining, and precision parts machining.