Production Line Launch: CATL Puts World-First Facility into Operation

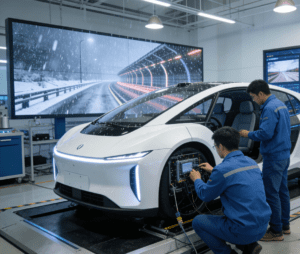

Recently, CATL announced that the world’s first new energy power battery PACK production line enabling the large-scale deployment of humanoid embodied intelligent robots has been officially put into operation at CATL’s Zhongzhou Base.

It is reported that the humanoid robot Xiaomo, which CATL has introduced for large-scale application this time, is developed by Qianxun Intelligent Robotics—an ecosystem partner of CATL—and equipped with self-developed batteries of CATL.

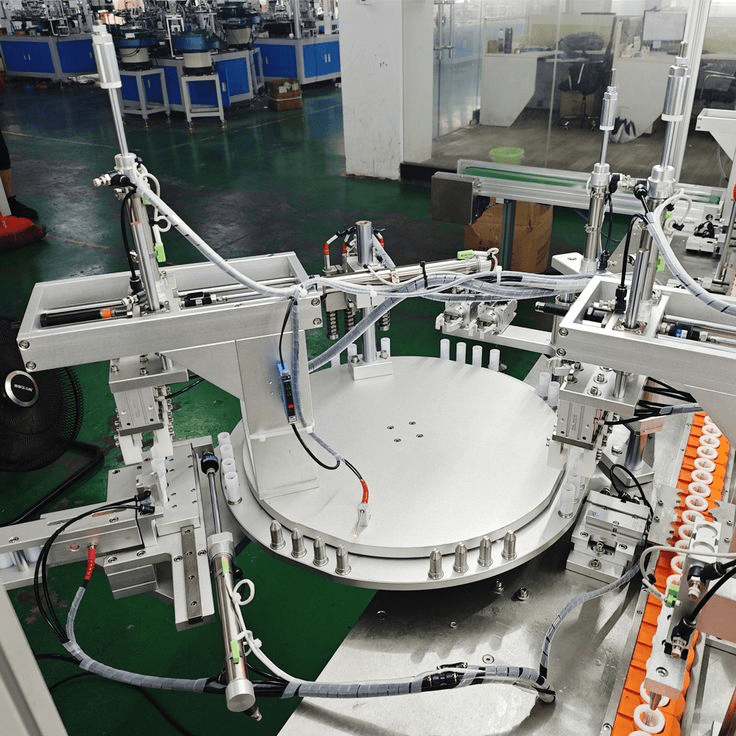

To translate actual on-site requirements into engineering and technical indicators, CATL collaborated with multiple departments to conduct in-depth research on the production line, and jointly formulated a development plan that is both forward-looking and feasible in implementation, laying a solid foundation for the large-scale deployment of embodied intelligent robots.

Xiaomo’s Practical Performance: High-Precision Operations & Stable Efficiency

In practical applications, Xiaomo has been able to accurately complete complex tasks such as the insertion and connection of battery connectors, as well as the precise assembly of contactor components through its integrated contactor assembly machine collaboration capability. Equipped with the self-developed end-to-end Vision-Language-Action (VLA) model, Xiaomo boasts strong environmental perception and task generalization capabilities: it can independently adapt to uncertainties such as deviations in incoming material positions, changes in insertion points, and subtle variations in contactor dimensions, adjusting its operating posture in real time; when plugging and unplugging flexible wire harnesses or assembling contactor terminals, it can dynamically regulate the force applied to ensure reliable connections, assembly accuracy, and no damage to sensitive components.

According to CATL, the success rate of connector insertion, contactor assembly, and related key processes by Xiaomo during actual operation has stably stayed above 99%, and its operation cycle has reached the level of skilled workers.

Moreover, Xiaomo can independently inspect the connection status of wire harnesses and the assembly precision of contactors, report abnormalities in real time, effectively reducing the defective rate, and actively switch to patrol mode during operation intervals. When tasked with the continuous production of multiple battery models with different contactor specifications, the daily workload of Xiaomo has tripled.

Qianxun Intelligent: R&D Breakthroughs & Commercialization Outlook

Founded in February 2024, Qianxun Intelligent Robotics is mainly committed to building a general model for embodied intelligence and driving technological breakthroughs and applications in robotics.

Last June, Qianxun Intelligent Robotics launched its first high-performance full-body force-controlled humanoid robot Moz1. This robot features 26 degrees of freedom across its body, is equipped with what is claimed to be the world’s most power-dense integrated force-controlled joints, and incorporates a high-precision and high-speed WBC algorithm, achieving a 1:1 payload-to-weight ratio.

Beyond robot hardware development, at the level of embodied models, Qianxun Intelligent Robotics’ self-developed VLA model Spirit v1 is also undergoing continuous iteration and upgrading. Currently, it can independently complete a series of continuous long-haul tasks such as folding clothes, tidying desks, and heating meals in microwaves. This not only overcomes the industry-wide challenge of flexible object manipulation, but also realizes generalized learning and execution capabilities across different task scenarios.

As previously disclosed by Qianxun Intelligent Robotics, the company expects to achieve mass commercial delivery in 2026, and reshape the commercialization path of embodied intelligence technology with its cross-scenario adaptability.