In the bathroom hardware industry, where “leak-proof performance,” “smooth operation,” and “aesthetic consistency” are core consumer demands, the bathroom faucet—though a daily-use item—has surprisingly complex assembly requirements. A standard faucet consists of 8–12 key components (valve body, ceramic valve core, handle, water outlet, inlet hoses, decorative covers, etc.), and traditional manual assembly faces persistent pain points: uneven torque during valve core installation leading to water leakage, misalignment of handle and valve body causing stuck operation, and low efficiency (a skilled worker can only assemble 30–50 units per hour). Against this backdrop, the Bathroom Faucet Assembling Machine has emerged as a game-changer, integrating automation, precision control, and quality inspection to redefine the standards of faucet production.

What Is a Bathroom Faucet Assembling Machine?

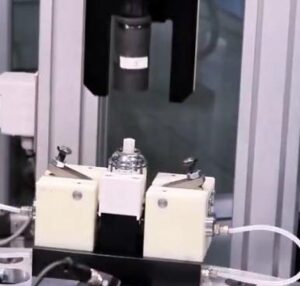

The Bathroom Faucet Assembling Machine is a specialized automated system designed for the integrated assembly of bathroom faucets (including single-hole, double-hole, thermostatic, and sensor-type faucets). Unlike general-purpose assembly equipment, it targets the unique characteristics of faucet components—such as irregular valve body shapes, high sealing requirements, and varied component combinations—and integrates three core workflows: component sorting & feeding, precision assembly of key parts, and in-line quality verification. Its core value lies in solving the “precision-inconsistency” and “efficiency-bottleneck” problems of manual assembly, ensuring that every faucet meets leak-proof, durable, and user-friendly standards.

Core Functions: How It Guarantees “Leak-Proof” and “Efficient” Assembly

A mature bathroom faucet assembling machine relies on modular design and intelligent control to cover the entire assembly process, with four key functional modules:

- Multi-Component Automatic Feeding: No Chaos, No Damage

Faucet components vary greatly in size and material—from small ceramic valve cores (diameter 15–20mm) to large valve bodies (weight 500–800g) and flexible inlet hoses. The machine uses targeted feeding solutions for different parts:

Vibratory Bowl Feeders: For small, uniform parts (e.g., decorative screws, O-rings), the feeder sorts and aligns components by vibration, ensuring they enter the assembly station in the correct orientation (e.g., O-rings with smooth sides facing outward to avoid sealing failure);

Robotic Arm with Vacuum Grippers: For fragile ceramic valve cores and heavy valve bodies, the gripper adjusts suction force (5–10N for valve cores, 30–50N for valve bodies) to prevent damage, while CCD visual positioning ensures parts are placed within ±0.1mm of the target position;

Hose Automatic Cutting & Crimping: For inlet hoses, the machine integrates a cutting module (to trim hoses to standard length, e.g., 300±2mm) and a crimping module (to fasten hose connectors to the valve body with uniform pressure), avoiding manual crimping that often leads to loose connections.

- Precision Assembly: The “Key” to Leak-Proof and Smooth Operation

The most critical steps in faucet assembly are valve core installation and handle alignment—both directly affecting leak-proof performance and user experience. The machine uses two core technologies to ensure precision:

Torque-Controlled Screwing: When installing the valve core (the “heart” of the faucet), the machine’s servo-driven screwdriver applies a preset torque (typically 2.5–3.5 N·m for ceramic valve cores). If the torque exceeds or falls below the range (e.g., due to a deformed thread), the system stops immediately and alerts, avoiding over-tightening that cracks the valve core or under-tightening that causes water leakage;

Visual-Assisted Handle Alignment: The handle and valve body have a “positioning notch” that must be perfectly aligned to ensure smooth rotation (no stuck or loose feelings). Two industrial cameras capture the notches of the handle and valve body in real time, correcting alignment errors within 0.5°, and the machine presses the handle into place with a stable force (10–15N), ensuring consistent tactile feedback across all products.

- In-Line Sealing Test: Reject Leaky Faucets at the Source

Water leakage is the biggest quality complaint for bathroom faucets—traditional post-assembly sampling tests (e.g., manual water injection) often miss hidden leaks. The Bathroom Faucet Assembling Machine integrates a high-pressure water tightness test module into the assembly line:

After assembly, the machine automatically connects the faucet’s inlet and outlet to a pressure test system, injecting water at 0.8MPa (equivalent to 8 times the normal household water pressure) and maintaining it for 30 seconds;

Sensors detect pressure drops (any drop >0.02MPa indicates a leak) and water seepage at joints (via infrared moisture detection). Defective products (e.g., due to O-ring misalignment or valve core damage) are automatically pushed to a rejection area, with a detection accuracy of 99.97%.

- Flexible Adaptation: Meet Diversified Faucet Designs

Today’s bathroom faucet market features diverse styles—single-hole basin faucets, double-hole bathtub faucets, thermostatic shower faucets, etc.—and the machine’s modular design ensures it can adapt quickly:

Quick-Change Fixtures: The valve body fixing fixture can be replaced in 10–15 minutes (vs. 2–3 hours for traditional equipment), and the machine stores parameters (torque, pressure test standards) for 20+ faucet models in its system;

Customizable Assembly Steps: For thermostatic faucets (which require additional temperature sensor installation), the machine can add a sensor calibration module without major modifications, making it suitable for both standard and high-end product lines.

Application Value: Empowering Bathroom Enterprises to Reduce Costs and Improve Quality

For large-scale (bathroom) manufacturers, the Bathroom Faucet Assembling Machine is not just an “automation tool” but a core driver of operational efficiency:

Efficiency Leap: A single machine can assemble 150–200 faucets per hour (3–4 times that of manual assembly) and run 24 hours a day with only 1 operator for supervision. A leading Chinese bathroom brand replaced 10 manual assembly lines with 3 such machines, increasing daily output from 1,200 to 3,600 units while cutting floor space by 40%.

Quality Stabilization: The machine’s precision control reduces the faucet leakage rate from 5–8% (manual assembly) to 0.3% or lower. A European brand using this equipment saw after-sales complaints related to faucet leakage drop by 75%, significantly improving brand reputation.

Labor Cost Savings: By automating repetitive tasks (screwing, pressure testing), enterprises reduce reliance on skilled workers (who are in short supply in the industry). Taking a medium-sized factory as an example, the machine cuts annual labor costs by 300,000–500,000 yuan, while avoiding training costs for new employees.

Future Trends: Toward Smarter and Greener Production

As the bathroom industry moves toward “intelligence” (e.g., smart sensor faucets) and “sustainability” (water-saving designs), the Bathroom Faucet Assembling Machine is also evolving in three key directions:

AI-Powered Defect Prediction: Integrating AI algorithms to analyze assembly data (torque fluctuations, pressure test results) and predict potential failures (e.g., a worn screwdriver head leading to unstable torque), enabling preventive maintenance and reducing unplanned downtime by 25–30%.

Smart Faucet Assembly Upgrade: Adding modules for installing electronic components (e.g., infrared sensors, touch panels) and calibrating smart functions (e.g., adjusting sensor response speed), adapting to the growing demand for smart bathroom products.

Green Energy Design: Adopting energy-saving servo motors and recyclable hydraulic oil for pressure testing, reducing the machine’s energy consumption by 15–20% compared with traditional models, in line with global carbon neutrality goals.

Conclusion: A “Small Machine” Driving the Upgrade of Bathroom Hardware

The Bathroom Faucet Assembling Machine may not be as “grand” as large-scale automotive assembly lines, but it plays a pivotal role in the bathroom hardware supply chain. It solves the long-standing pain points of manual assembly—low precision, high defects, and inefficiency—and helps enterprises meet the increasingly strict quality requirements of global markets.

In the future, as consumers demand more from bathroom faucets (e.g., higher leak-proof performance, smarter functions, more personalized designs), the Bathroom Faucet Assembling Machine will continue to iterate, becoming an indispensable part of the “smart bathroom manufacturing ecosystem.” For bathroom enterprises seeking to gain a competitive edge, investing in this precision equipment is not just a choice for today, but a layout for the future.