From fingerprint recognition in smartphones to equipment monitoring in smart factories, from heart rate sensing in wearable devices to environmental detection in autonomous driving, sensors, as the “nerve endings of the intelligent world,” are supporting the operation of a trillion-level Internet of Things (IoT) ecosystem. Behind every sensor that can accurately capture physical signals, there is the “exquisite craftsmanship” of the sensor printing and packaging integrated machine. This equipment, which integrates “core sensing layer manufacturing” and “protective packaging,” is not only the “definer” of sensor performance but also the “accelerator” for its large-scale implementation, reshaping the production logic of the intelligent sensing industry at the millimeter or even micrometer scale.

Integrated Molding: Seamless Connection from “Drawing Sensing” to “Wearing Protection”

The core value of the sensor printing and packaging integrated machine lies in compressing the two most critical links in sensor production—”sensing layer printing” and “functional packaging”—into a coherent assembly line, completely breaking the efficiency bottleneck of traditional step-by-step production.

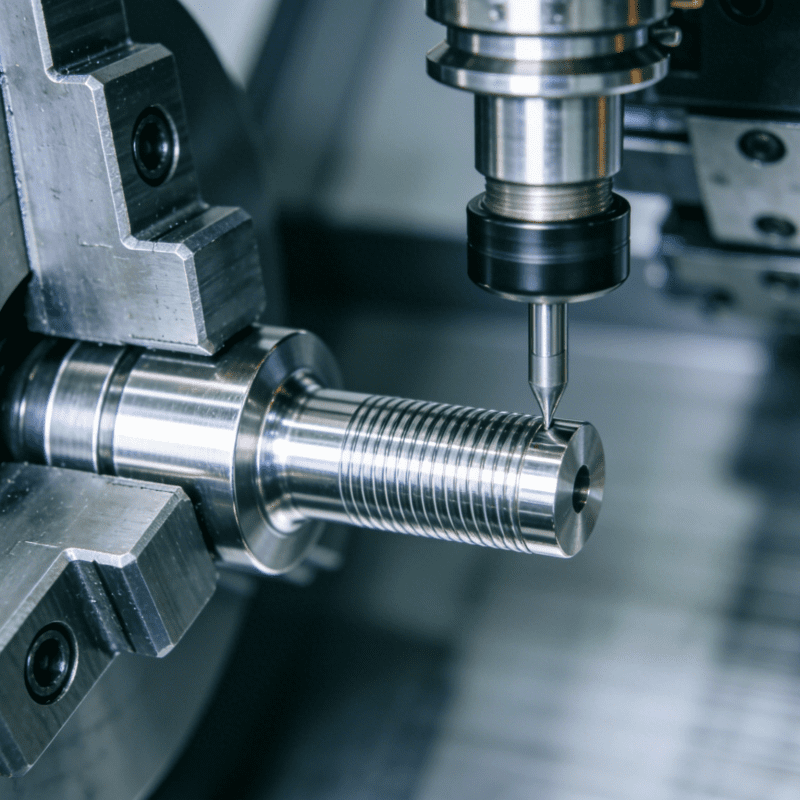

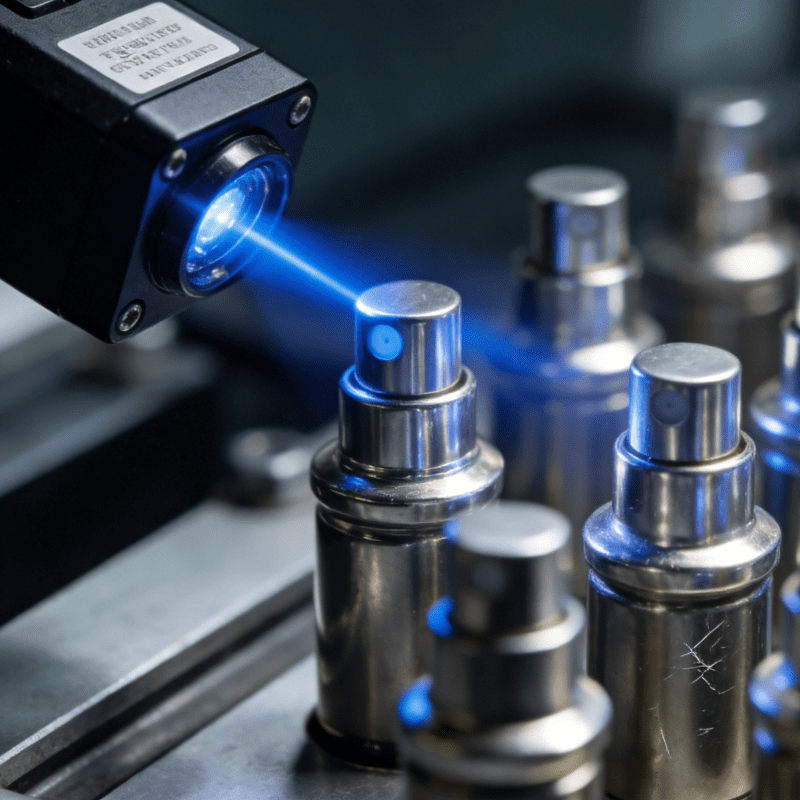

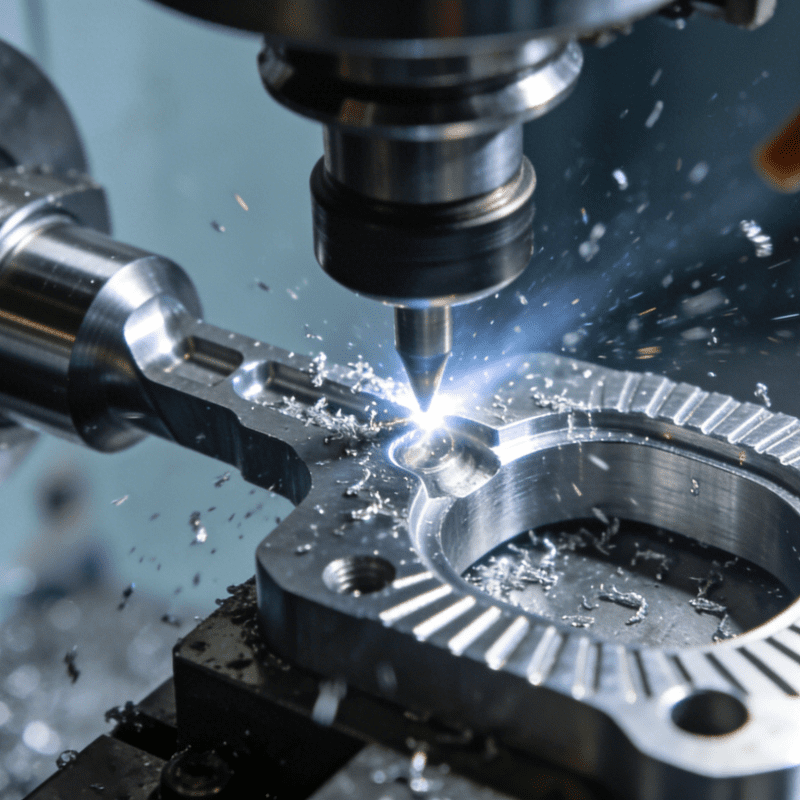

“Sensing layer printing” is the foundation for endowing sensors with “sensing capabilities.” It requires “drawing” functional materials such as conductive inks, semiconductor materials, or sensitive films onto the substrate with almost harsh precision. For example, when manufacturing a heart rate sensor for a smart bracelet, the equipment needs to use screen printing or inkjet technology to “draw” an electrode grid with a width of only 30μm on a 0.5mm thick flexible PI film—this precision is equivalent to carving fine runway patterns on a fingernail, ensuring that the current can uniformly respond to resistance changes caused by blood flow. For industrial pressure sensors, laser etching technology is also used to “carve” micrometer-level pressure-sensitive cavities on ceramic substrates, allowing the sensor to capture tiny pressure changes at the 0.1Pa level.

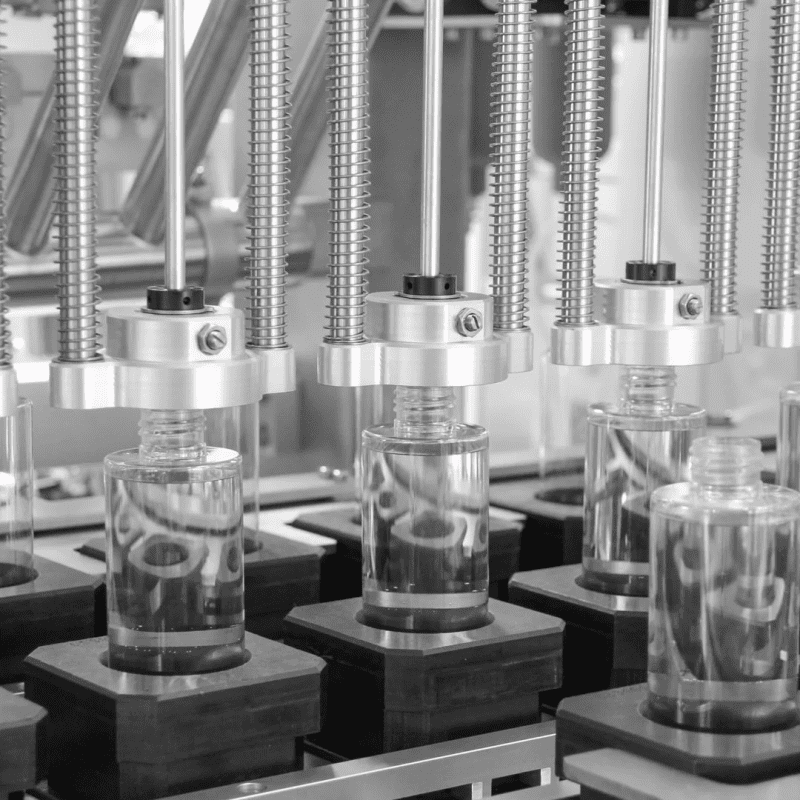

“Functional packaging” is the guarantee of sensor durability. After “drawing,” the equipment needs to put a “protective coat” on the fragile sensing layer: for automotive millimeter-wave radar sensors, ultrasonic welding of aluminum alloy shells is used to achieve IP6K9K dust and water resistance, while embedding an electromagnetic shielding layer to resist complex interference in the engine compartment; for medical skin-attached sensors, sterile film heat-sealing technology is adopted to ensure biocompatibility while isolating sweat corrosion; for industrial pipeline sensors, inert gas is even injected during packaging to prevent the sensing layer from being oxidized by chemical gases.

This integrated process of “printing-drying-detection-packaging” reduces the precision loss caused by material transfer in traditional production by 80%, and the daily output of a single production line can be increased to more than 50,000 units, clearing the production obstacles for the large-scale application of sensors.

Reshaping the Industry: Leap from “Customization” to “Inclusiveness”

The popularization of sensor printing and packaging integrated machines is fundamentally changing the development logic of the sensing industry.

It has turned sensors from “customized luxury goods” into “large-scale consumer goods.” Ten years ago, the production cycle of an industrial-grade pressure sensor took 72 hours, and the cost per unit exceeded 100 yuan; today, through integrated equipment, the production cycle is shortened to 8 hours, and the cost per unit is reduced to less than 20 yuan, promoting the popularization of sensors in scenarios such as agricultural greenhouses and smart homes.

It is also accelerating the commercialization of new sensors. Technologies that once stayed in the laboratory, such as flexible electronic skin and self-healing strain sensors, can be quickly mass-produced because the equipment is compatible with flexible substrate printing and elastic material packaging—for example, stretch sensors that can be attached to sportswear can real-time monitor muscle movement amplitude, helping athletes optimize their movements.

In the future, with the integration of 5G and digital twin technology, such equipment will also realize “remote debugging + predictive maintenance”: engineers can adjust printing parameters through the cloud, and the AI system will early warn of faults based on equipment vibration, temperature and other data, further reducing the manufacturing threshold of high-end sensors.

In this data-driven intelligent era, sensors are the bridge connecting the physical world and the digital world. The sensor printing and packaging integrated machine is precisely the “founder” of this bridge—it supports the intelligent transformation of the macro world with micrometer-level precision, making every perception more accurate and every connection more reliable.