Table of Contents

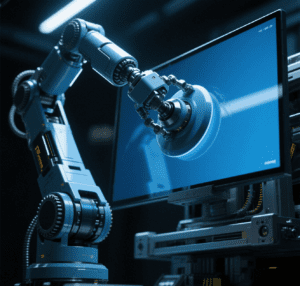

ToggleRobotized Display Pick-and-Place System: Revolutionizing Precision Handling in Display Manufacturing

In the high-stakes world of display manufacturing, handling delicate panels (ranging from 10″ smartphone screens to 100″+ TV displays) with absolute precision is non-negotiable. Traditional manual or semi-automated pick-and-place methods suffer from critical flaws: slow cycle times (20–40 seconds per panel), positional errors (±0.5mm), and high risk of panel damage (defect rates ≥1%). The Robotized Display Pick-and-Place System emerges as a transformative solution, integrating high-precision robotics, AI-driven vision, and adaptive gripping to enable seamless handling of OLED, LCD, and micro-LED panels in high-volume production.

I. Core Technical Architecture: Precision Meets Delicacy

The system’s modular design balances robotic agility with display-specific fragility, comprising three interdependent subsystems:

1. High-Precision Robotic Manipulation Unit

Powered by 6-axis articulated robots (e.g., Fanuc M-20iD/35M) or gantry-style Cartesian robots, the system delivers:

- Sub-Millimeter Handling Precision: ±0.05mm repeatability for 10–150kg panels, critical for aligning micro-LED arrays or foldable display hinges;

- Adaptive Vacuum Gripping: Customizable suction cup arrays (4–12 cups) with pressure sensors (deviation <0.1kPa) for non-porous surfaces, and hybrid mechanical grippers for framed displays;

- Zero-Vibration Motion Control: Anti-shake algorithms and carbon fiber arms minimize panel vibration during transport, essential for thin OLED panels (≤0.3mm thickness).

2. AI-Vision Guided Alignment Ecosystem

A triple-camera vision setup ensures micron-level accuracy:

- Stereo 3D Camera System: Reconstructs panel geometry with 0.01mm resolution, correcting ±15mm positional deviations for curved displays (curvature radius ≥500mm);

- AI Defect Detection: Deep learning models (e.g., EfficientNet) identify micro-cracks, dust particles, or alignment markers with 99.9% accuracy on glossy surfaces;

- Dynamic Refraction Compensation: Corrects for light distortion in transparent panels using polarized lighting, ensuring precise pick points.

3. Intelligent Control & Safety Network

Powered by industrial PCs with real-time OS:

- Recipe Management: Stores 200+ panel specifications (size, curvature, fragility) for 3-minute changeovers, supporting rapid shifts between smartphone and TV panels;

- ESD-Compliant Design: Conductive grippers and ionizing blowers maintain <100V surface potential, critical for OLED pixel integrity;

- Laser Safety Grilles: Create 0.1-second response zones around handling areas, meeting ISO 13849 PLd safety standards.

II. Industrial Applications: From Micro-LED to Automotive Displays

1. Large-Screen TV Panel Manufacturing

- 8K OLED Panel Handling: Vacuum grippers lift 75″–100″ panels with ±0.1mm vertical alignment, supporting bezel-less designs (bezels ≤2mm);

- Curved TV Assembly: 3D vision generates adaptive trajectories for 10°–15° curved panels, preventing stress-induced pixel damage.

Case Study: A Korean display OEM reduced panel damage by 92% and increased throughput by 50% after deploying 40 systems, achieving 24/7 operation with 99.8% uptime.

2. Mobile Device & Wearables

- Foldable Display Handling: Dual-gripper modules handle 7″ foldable screens with ±0.02mm precision, supporting hinge alignment for seamless folding;

- Smartwatch Micro-LED Placement: SCARA robots place 0.1mm×0.1mm micro-LEDs with sub-micron accuracy, enabled by piezo-electric microgrippers.

3. Automotive HMI & Cockpit Displays

- Dashboard Display Integration: Magnetic grippers handle 15″–21″ curved cockpit displays, with force control (5–20N) to withstand vehicle vibration;

- Head-Up Display (HUD) Alignment: Vision systems ensure ±0.5° angular accuracy for HUD projectors, critical for driver safety.

III. Competitive Advantages Over Traditional Systems

| Performance Metric | Manual/Semi-Automated | Robotized Pick-and-Place |

| Cycle Time (55″ Panel) | 20–40 seconds | 8–15 seconds |

| Positioning Accuracy | ±0.5mm | ±0.05mm (X/Y), ±0.1mm (Z) |

| Panel Damage Rate | 0.8–1.5% | <0.03% |

| Changeover Time (new panel) | 15–30 minutes | <3 minutes (auto-calibration) |

IV. Future Innovations

AI-Driven Autonomous Handling

- ML models analyze 100,000+ handling cycles to predict optimal grip points for new panel designs, reducing trial-and-error by 80%

5G-Powered Edge Computing

- Real-time data from 50+ sensors (pressure, vibration, temperature) enables millisecond-level collision avoidance in multi-robot cells.

Sustainable Design Paradigms

- Regenerative drives recover 35% of braking energy, and biodegradable vacuum cup materials reduce waste in display recycling lines.

Conclusion

The Robotized Display Pick-and-Place System represents a quantum leap in precision material handling, addressing the unique challenges of fragile, high-value display panels. By merging robotic accuracy, AI vision, and display-specific engineering, it enables manufacturers to tackle next-generation display technologies—from foldables to micro-LED—with unprecedented reliability. As display technologies continue to push boundaries, these systems will evolve into self-optimizing cyber-physical systems, ensuring every panel is handled with the care and precision it demands.

#Robotized Display Pick-and-Place System #ision-Guided Display Handling #High-Precision Panel Automation