The global perfume market is moving towards high-endization and diversification, with consumers paying more attention to the quality and user experience of perfume sprayers. However, traditional perfume sprayer production relies on manual or semi-automatic assembly, which is plagued by problems such as poor sealing, high leakage rates, low efficiency, and difficulty in adapting to multi-specification production. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing is driving the transformation of the cosmetic industry with high-precision and flexible perfume sprayer assembly machines, reshaping the production pattern of the industry.

The Pain Points of Traditional Perfume Sprayer Production: The Urgency of Automation Upgrade

Perfume sprayers have strict requirements for sealing and precision, but traditional manual assembly is prone to problems such as uneven assembly force and misalignment of components, resulting in a leakage rate of more than 5%. At the same time, the market has diverse demands for sprayer specifications (such as different nozzle calibers and pump core models), and standardized equipment can only meet fixed production needs, making it difficult for factories to respond quickly to market changes. In addition, rising labor costs and low manual production efficiency (only 30-40 pieces per minute) further restrict the development of enterprises.

Ruizhi’s Perfume Sprayer Assembly Machine: Core Advantages Driving Industrial Transformation

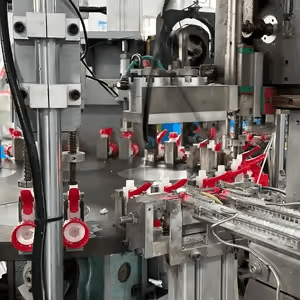

Targeting the pain points of the industry, Ruizhi’s non-standard perfume sprayer assembly machine integrates precision control, flexible adaptation and automatic inspection, bringing revolutionary changes to production. Firstly, with customized non-standard design, it can be tailored to different sprayer specifications, and the production line can be switched in 10-20 minutes, easily meeting the diversified production needs of enterprises. Secondly, adopting precision servo control and airtightness testing technology, the production efficiency is increased by 2-3 times compared with manual work, and the leakage rate is reduced to less than 0.3%. Finally, the integrated automatic inspection module can timely screen out defective products, ensuring stable product quality.

One-Stop Service: Ruizhi’s Escort for Enterprise Transformation

The transformation of perfume sprayer production is not only about equipment replacement, but also requires professional overall solutions. Ruizhi Intelligent Manufacturing provides one-stop services from demand communication, scheme design, equipment customization to on-site installation and after-sales maintenance. Our engineering team with rich experience in the cosmetic industry will fully consider the factory layout, production capacity and quality requirements of customers to create the most suitable assembly solution. The perfect after-sales support system ensures timely technical guidance and maintenance services, solving the worries of enterprises in the process of equipment use.

In the fiercely competitive cosmetic market, perfume sprayer assembly machines have become a key factor for enterprises to gain competitive advantages. Ruizhi Intelligent Manufacturing relies on professional non-standard automation technology to help cosmetic factories break through production bottlenecks, improve product quality and efficiency, and seize market opportunities. Choose Ruizhi’s perfume sprayer assembly machine to inject strong momentum into the high-quality development of your enterprise.