Lipstick assembly involves core links like core positioning, tube fitting, and cap sealing, which directly affect product quality and production efficiency. Cosmetic factories often struggle with core misalignment, low adaptability to multi-style orders, and high labor costs. Ruizhi Intelligent Manufacturing summarizes three key optimization directions, empowering factories with non-standard automation solutions to achieve high-quality and efficient production.

Achieve Millimeter-Level Precision

Core misalignment is a major cause of lipstick defects. Ruizhi solves this by integrating AI visual inspection and high-precision servo systems into non-standard assembly machines. The AI system captures core position in real time, identifying 0.01mm-level deviations, while servo drives dynamically adjust positioning to ensure assembly precision of ±0.02mm. This reduces defect rates from over 8% to below 1%, ensuring consistent product appearance and performance.

Tackle Multi-Style Production

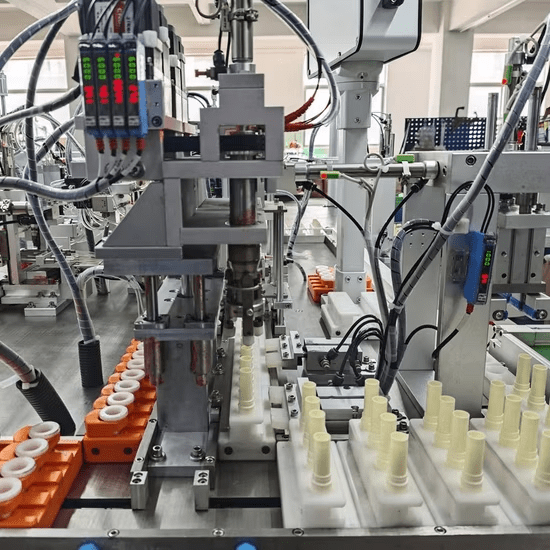

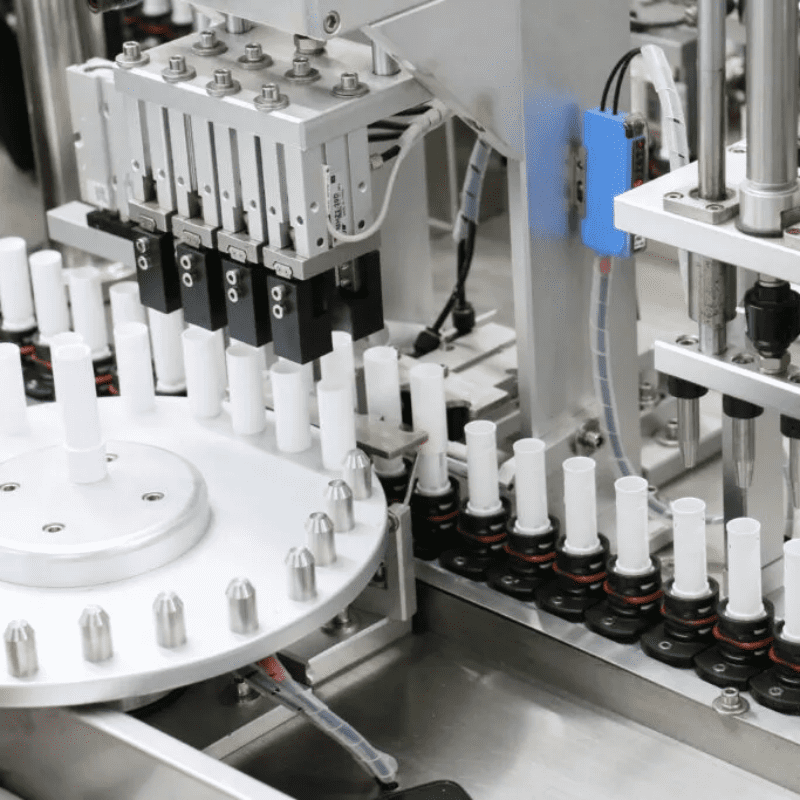

Diverse lipstick styles (twist-up, bullet, slim) pose challenges to assembly efficiency. Ruizhi’s non-standard solutions adopt quick-change modular design, with customized clamping modules for different tube shapes. Operators can switch between styles in just 4 minutes without professional debugging, reducing batch change downtime by over 85%. Flexible clamping technology also avoids tube scratches, adapting to small-batch and multi-variety production demands.

Cut Labor & Boost Efficiency

Traditional manual assembly is inefficient and error-prone. Ruizhi’s fully automatic non-standard machines integrate feeding, positioning, assembly, and inspection into one line, replacing 8-10 manual workers. Equipped with intelligent PLC control systems, the whole process runs automatically, with real-time data monitoring for production traceability. Energy-saving motors and GMP-compliant components (316L stainless steel) further reduce operational costs and meet industry norms.

Ruizhi Intelligent Manufacturing focuses on customized non-standard automation. By optimizing precision, adaptability, and automation, we help cosmetic factories break through lipstick assembly bottlenecks and gain a competitive edge in the fast-paced market.