With the continuous development of industrial technology, precision manufacturing processes have become the core driving force behind the advancement of high-end products. In industries such as medical devices, stage lighting, and life sciences, the precision of components directly impacts product performance, safety, and user experience. This is particularly true in the production of medical equipment parts and precision components for stage lighting, where the importance of precision manufacturing processes cannot be overstated. From a popular science perspective, this article will provide a detailed analysis of how precision manufacturing processes enhance these two fields.

What is Precision Manufacturing Process?

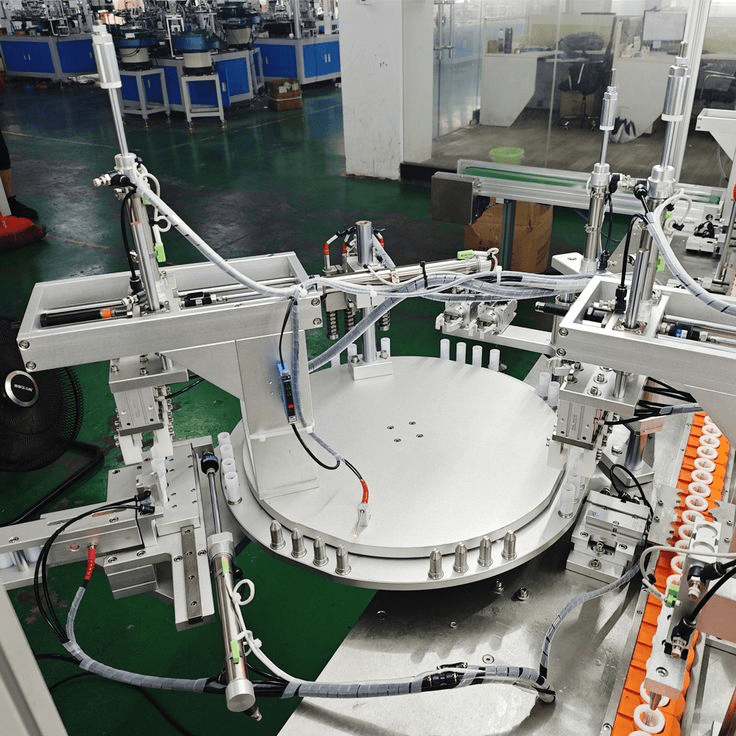

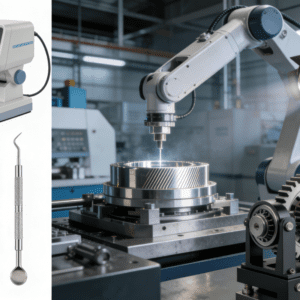

Precision manufacturing process refers to the process of processing raw materials into components with dimensions, shapes, and surface quality that meet strict standards using high-precision equipment and advanced processing technologies. This includes not only traditional mechanical processing but also modern technologies such as numerical control machining, laser processing, ultrasonic processing, precision mold manufacturing, and micro-nano surface treatment.

Compared with general manufacturing processes, precision manufacturing emphasizes error control and repeatability. For example, in the machining of medical equipment parts, a micrometer-level deviation in a single component may affect the accuracy of the entire device. In the case of precision components for stage lighting, even a minor structural deviation can lead to beam offset or abnormal mechanical operation. Therefore, precision manufacturing requires not only advanced equipment but also strict process flow and a highly skilled operation team.

The Enhancement of Precision Manufacturing Processes on Medical Equipment Parts

Medical equipment has extremely high requirements for the precision, durability, and reliability of its components. Each component can directly impact diagnostic and therapeutic outcomes, and even patient safety. Through precision manufacturing processes, medical equipment parts are significantly improved in the following aspects:

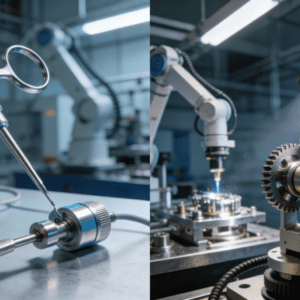

Significant Improvement in Machining AccuracyPrecision manufacturing can drastically enhance the machining accuracy of components. Modern medical equipment, such as surgical instruments, imaging devices, or laboratory analytical instruments, requires extremely strict tolerances for component dimensions. Precision manufacturing processes can control machining errors to the micrometer level, ensuring that components perfectly match the entire device. This high-precision machining not only improves the stability of the equipment but also makes operations smoother, enabling medical professionals to achieve more accurate diagnoses and treatments.

Extended Service Life of ComponentsHigh-precision components experience less friction and wear, making them less prone to deformation. For medical equipment that requires continuous operation over long periods, precision manufacturing not only reduces the frequency of equipment maintenance but also lowers overall operational costs. Additionally, high-quality components can reduce equipment failure rates, ensuring the smooth operation of medical institutions.

Enhanced Safety of EquipmentIn the medical field, even the smallest deviation can lead to misdiagnosis or treatment risks. Precision manufacturing processes ensure that every component meets strict standards, providing reliable and safe equipment from the source. This is why many high-end medical equipment manufacturers consider precision manufacturing capabilities as a crucial factor when selecting suppliers.

The Enhancement of Precision Manufacturing Processes on Stage Lighting Accessories

Compared with medical equipment, the components of stage lighting play a key role in the entertainment and performance industry. Precision components for stage lighting typically include optical brackets, gear mechanisms, slide rails, and heat dissipation parts. The impacts of precision manufacturing processes on these accessories are reflected in multiple aspects:

Guaranteed High Precision of Optical and Mechanical StructuresStage lighting requires precise beam control and smooth movement. Any minor deviation in components can affect lighting effects, leading to issues such as beam offset or mechanical jamming. Precision manufacturing processes can control component dimensions within tight tolerances, ensuring that the optical and mechanical performance of stage lighting meets design standards.

Reduced Noise and Failure RatesStage lighting needs to operate continuously for long periods during performances. High-precision components fit tightly together, reducing friction and mechanical vibration, resulting in more stable and quieter operation of the lighting system. This minimizes the impact of sudden failures on performances and extends the overall service life of the lighting equipment, providing a reliable guarantee for performances and tours.

Increased Design FlexibilityHigh-precision machining enables the realization of more complex structures and miniaturized designs, making stage lighting lighter and more versatile. For example, some new types of stage lighting use precision gears and micro-motors to achieve adjustable beams, multi-angle rotation, and precise light-tracking effects—all made possible by precision manufacturing technology.

The Driving Role of Precision Manufacturing Processes in Overall Industrial Value

Beyond medical equipment and stage lighting, the value of precision manufacturing processes is increasingly prominent across the entire industrial sector. It not only improves product quality and performance but also drives industrial technological upgrading and innovation. Through precision manufacturing, lighter, smaller, and more efficient components can be produced to meet the demands of modern industry for high-performance and highly reliable products.

Furthermore, precision manufacturing processes are equally important in the R&D phase. Designers and engineers can use precision machining to verify prototypes and test complex structures, enabling rapid iteration of design solutions. This capability not only shortens product development cycles but also reduces R&D costs, giving enterprises a stronger competitive edge in the market.

Conclusion

In summary, precision manufacturing processes are not merely a technical tool but also a key guarantee for enhancing the quality and performance of high-end products such as medical equipment and stage lighting. For medical equipment parts, they ensure high precision, reliability, and safety; for precision components of stage lighting, they guarantee optical accuracy, mechanical stability, and design innovation capabilities.

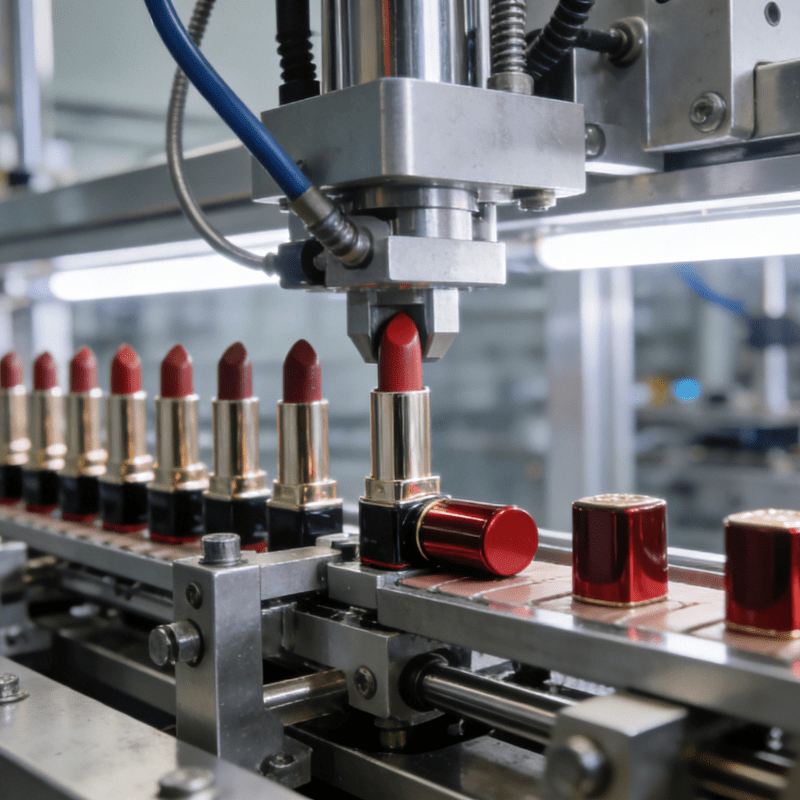

Assembly line for mass production by artificial intelligence