The cost of automated robots is not a single figure, but varies significantly depending on their type, functional complexity, and supporting services. According to 2025 market data, their prices range from $25,000 for basic collaborative robots to over $500,000 for complete industrial automation systems, and even exceed $200,000 for advanced humanoid AI robots. This variation stems not only from hardware specifications but also from deep ties to “hidden costs” such as software functions, installation and integration, and training support. This article systematically breaks down the cost structure of automated robots, sorts out key influencing factors with practical cases (e.g., the RO1 6-axis robot), and provides cost optimization suggestions to help enterprises accurately match their needs with budgets.

Core Price Ranges of Automated Robots: Classified by Type and Application Scenario

Different types of automated robots have significant differences in their basic purchase prices due to varying design objectives (e.g., collaboration, load capacity, intelligence level). Enterprises need to choose based on their own production scenarios:

Collaborative Robots (Cobots): $25,000 – $150,000, Suitable for Human-Robot Collaboration Scenarios

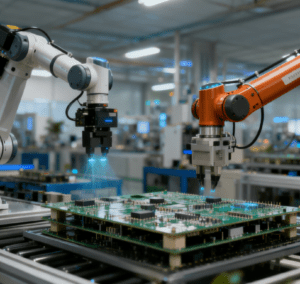

Core Positioning: No safety fences required; can work in close proximity to humans (e.g., assisting workers with loading/unloading materials, assembling small parts). Load capacity typically ranges from 3kg to 16kg, with precision between ±0.1mm and ±0.05mm.Typical Applications: PCB board handling in electronics factories, auxiliary assembly of automotive components, quality inspection of 3C products.Price Examples:

Basic models (e.g., 5kg load, 800mm working radius): Starting at approximately $25,000.

Advanced models with built-in vision systems (e.g., RO1 6-axis collaborative robot): Approximately $50,000 – $80,000.

High-end brands (e.g., Universal Robots UR10e): Up to $120,000 – $150,000.

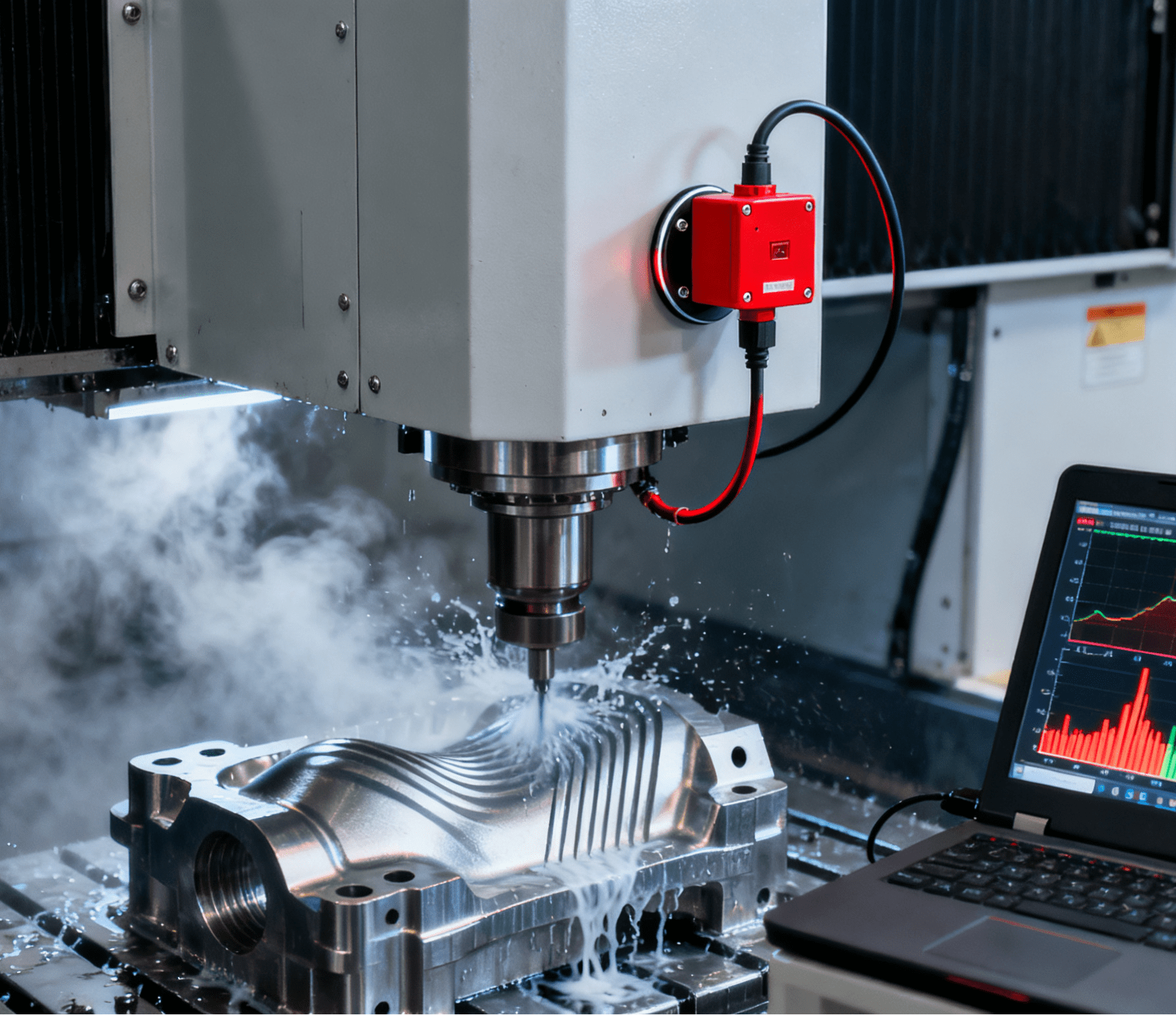

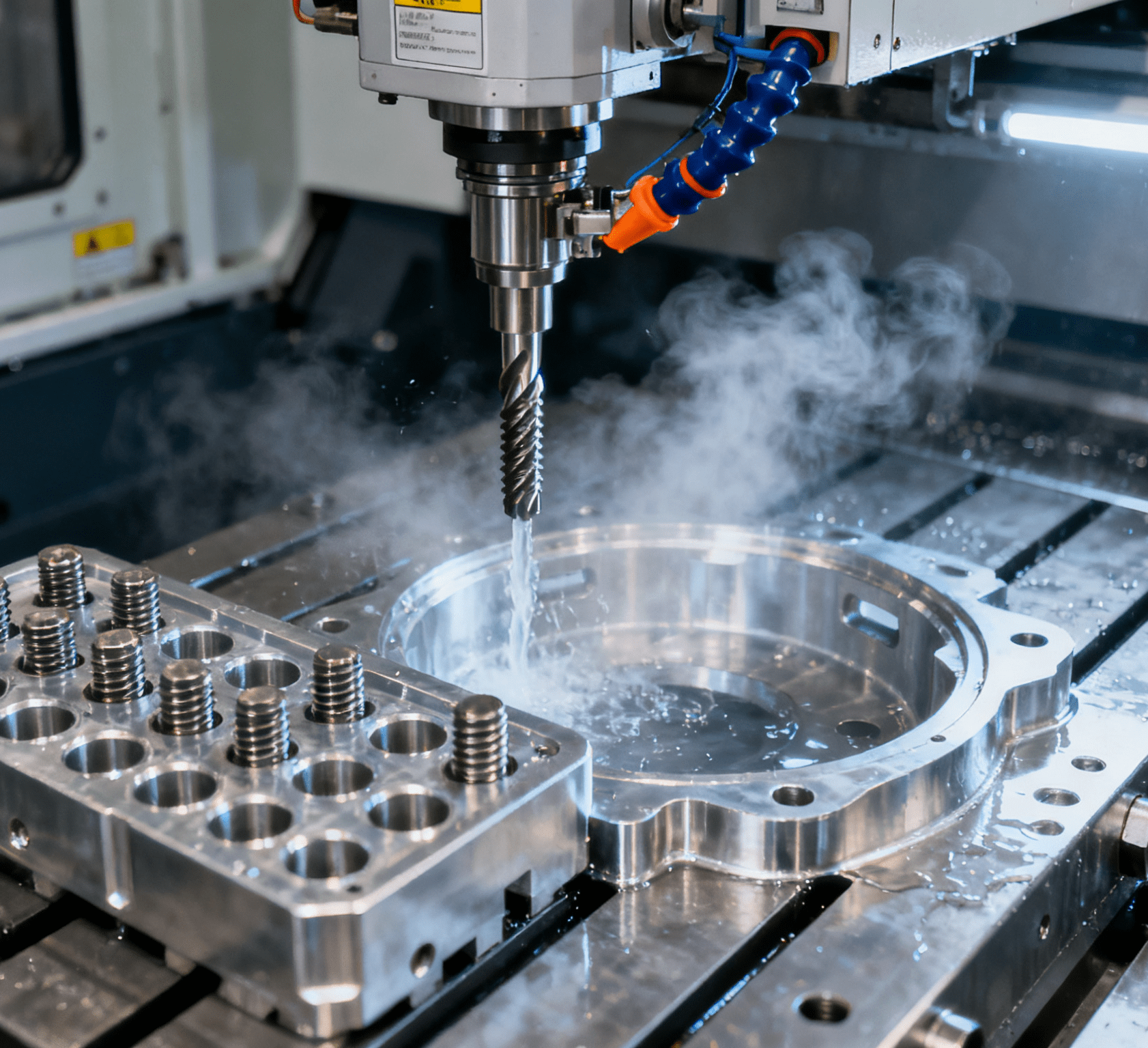

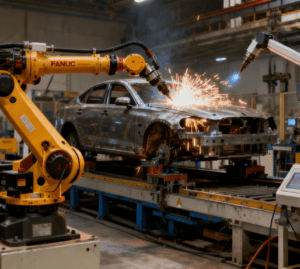

Industrial Robots (Single Unit): $80,000 – $500,000, Suitable for High-Intensity Automation Tasks

Core Positioning: Independently perform high-load, high-speed, or high-precision tasks (e.g., welding, heavy material handling, precision grinding). Load capacity ranges from 10kg to 500kg, with precision up to ±0.02mm – ±0.005mm.Typical Applications: Automotive body welding, new energy battery handling, loading/unloading for metal processing machines, and specialized medical device assembly such as thermometer visual labeling machines—these devices integrate SCARA robots with 2D vision systems to ensure labels are accurately aligned on thermometer casings (critical for reading temperature scales and product information) and avoid misalignment that could render medical thermometers unusable.Price Examples:

6-axis welding robots (15kg load, with welding torch): Approximately $120,000 – $180,000.

Heavy-duty handling robots (100kg load, 2000mm working radius): Approximately $300,000 – $500,000.

Thermometer visual labeling machines (SCARA robot + 2D vision + custom labeling fixture): Approximately $100,000 – $150,000, with visual positioning modules accounting for ~30% of costs and custom fixtures adding an extra $15,000 – $25,000.

Imported brands (e.g., FANUC M-20iA): 30% – 50% more expensive than domestic counterparts of similar specifications.

Complete Industrial Automation Systems: $500,000 – $5,000,000+, Suitable for Full-Process Automation

Core Positioning: Composed of multiple robots, conveyors, visual inspection modules, and control systems, enabling fully unmanned processes from “material loading → processing → assembly → inspection → material unloading”.Typical Applications: Automotive transmission assembly lines, consumer electronics complete machine assembly lines, aseptic assembly lines for medical equipment.Price Examples:

Simplified automotive component assembly systems (2 robots + conveyor belt + basic inspection): Approximately $500,000 – $800,000.

High-end electronic complete lines (with 5+ robots, 3D vision, MES integration): Approximately $2,000,000 – $5,000,000.

Precision component assembly systems for aerospace: Exceeding $5,000,000.

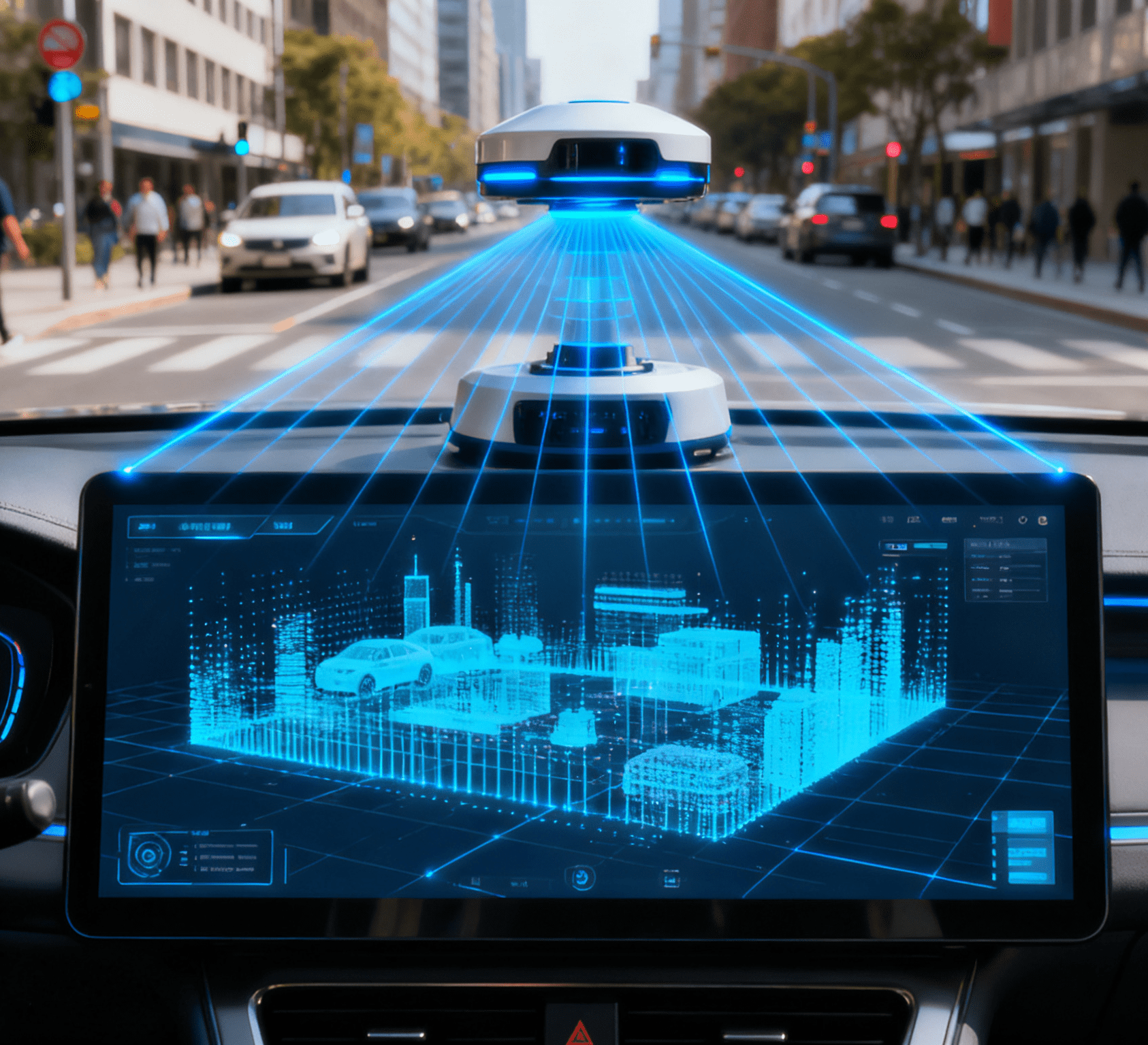

Humanoid AI Robots: $200,000 – $1,000,000+, Suitable for Complex Scenario Interaction

Core Positioning: Feature human-like forms (head, torso, limbs) and integrate AI voice interaction, environmental perception, and adaptive motion capabilities. Capable of performing tasks in unstructured scenarios (e.g., service reception, complex equipment maintenance).Typical Applications: Equipment inspection in high-end manufacturing, commercial services (e.g., hotel reception), operations in special environments (e.g., nuclear power plant inspection).Price Examples:

Basic service-oriented humanoid robots (with voice interaction, simple grasping functions): Approximately $200,000 – $350,000.

Industrial-grade humanoid robots (10kg load, with force feedback): Approximately $500,000 – $800,000.

High-end models with multimodal AI (e.g., autonomous obstacle avoidance, complex task planning): Exceeding $1,000,000.

Breakdown of Cost-Driving Factors: Full-Cycle Impacts from Hardware to Software

The total cost of an automated robot, beyond the basic purchase price, is influenced by multiple factors including hardware specifications, software functions, and integration services. Each choice can lead to a 20% – 100% cost fluctuation:

Hardware Specifications: Load Capacity, Axis Count, and Precision Are Core Variables

Hardware forms the “foundation” of costs, with payload capacity, axis count, and precision tolerance being the most critical pricing factors:

Payload Capacity (Load Ability): Costs rise exponentially with increasing load capacity. For example:

Robots with 5kg load (for small parts): Basic price of $25,000 – $50,000.

Robots with 50kg load (for medium-sized components): Basic price of $150,000 – $250,000.

Robots with 200kg load (for heavy equipment): Basic price of $400,000 – $800,000.

The reason is that high-load robots require more powerful motors, more robust body structures (e.g., high-strength aluminum alloy or steel), and more stable transmission systems (e.g., precision gearboxes). These components account for 40% – 60% of the total machine cost.

Axis Count and Flexibility: More axes mean higher motion freedom for the robot and higher costs. For example:

4-axis robots (mostly SCARA structure, for planar tasks like insertion and handling—such as the SCARA robots in thermometer visual labeling machines): Basic price of $80,000 – $120,000.

6-axis robots (for complex spatial movements like welding and assembly, e.g., RO1): Basic price of $120,000 – $200,000.

7-axis robots (with redundant axes, for flexible operations in narrow spaces): Basic price of $250,000 – $400,000.

Multi-axis designs require additional motors, encoders, and control modules. Each additional axis increases costs by approximately 15% – 25%.

Precision and Sensors: Higher precision requirements demand more sophisticated sensors and drive systems, leading to significant cost increases. For example:

Ordinary precision (±0.1mm, for general assembly): No additional cost.

High precision (±0.02mm, for electronic component alignment or thermometer label positioning): Requires laser displacement sensors or linear scales, increasing costs by $10,000 – $30,000.

Ultra-high precision (±0.005mm, for aerospace parts): Requires a combination of servo motors and torque sensors, increasing costs by $50,000 – $100,000.

Additionally, built-in safety sensors for collision detection and force feedback can increase the basic price by 10% – 20% (e.g., force control sensors in collaborative robots to prevent injury during human-robot collisions).

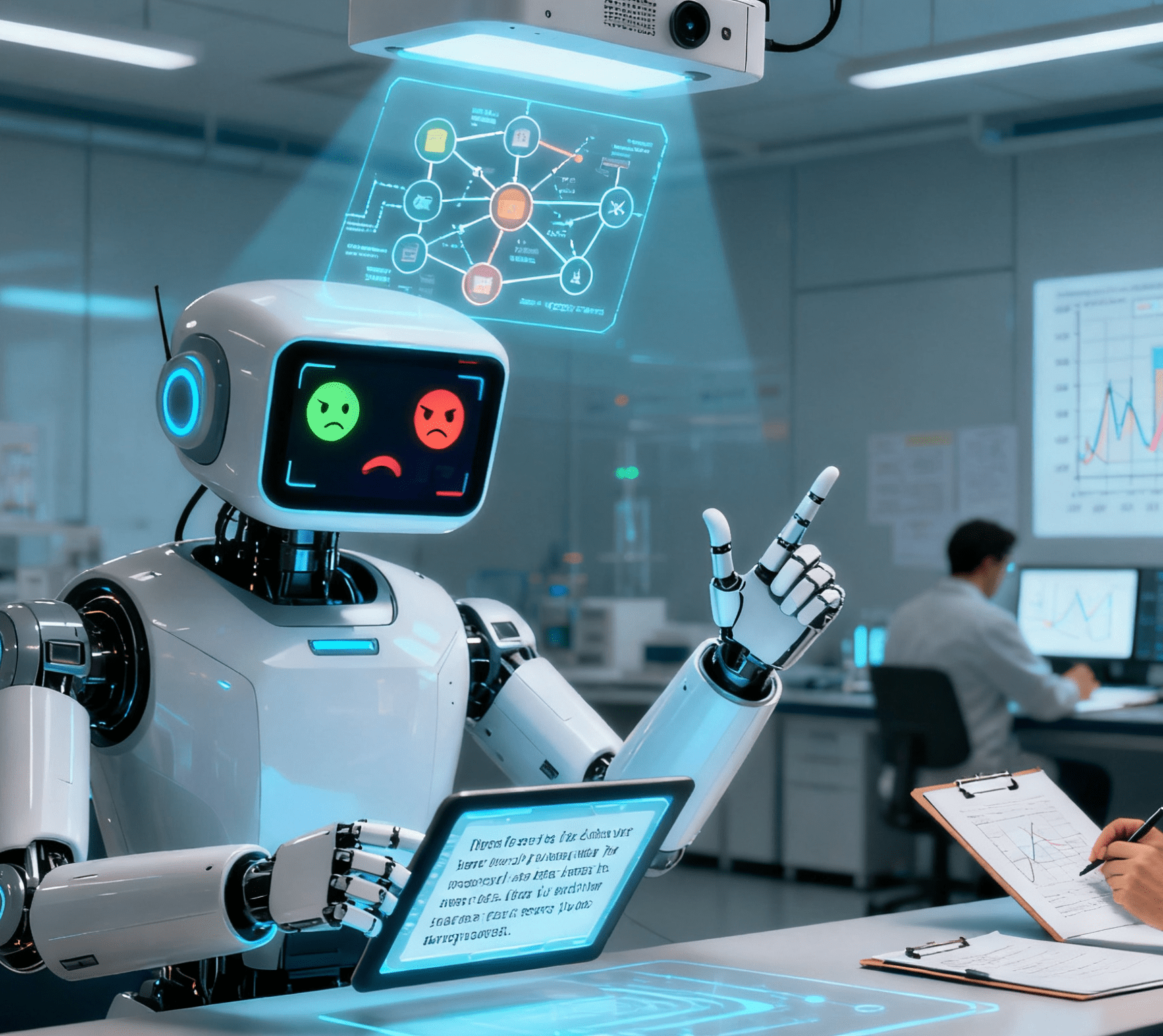

Software and AI Functions: Vision and AI Are Major Premium Drivers

Software functions directly determine the “intelligence level” of a robot and are also an important source of cost differences:

Vision Systems: Used for part positioning, defect detection, and barcode recognition, they are essential for most industrial scenarios. Cost differences lie in “third-party procurement” vs. “built-in integration”:

Third-party vision systems (e.g., Cognex In-Sight, Keyence IV2): Separate purchase price of $10,000 – $30,000, plus additional integration and debugging fees of $5,000 – $15,000, resulting in a total cost of $15,000 – $45,000. This is often the choice for customized thermometer visual labeling machines that require compatibility with multiple thermometer models.

Built-in vision systems (e.g., 2D vision in RO1 robots): No additional cost, requiring only software activation, saving $15,000 – $40,000.

3D vision systems (for irregular part positioning) are more costly: Third-party solutions cost approximately $50,000 – $100,000, while built-in solutions require an additional $100,000 – $150,000 on top of the basic price.

AI Functions: Include machine learning (autonomous optimization of motion paths), adaptive motion (adapting to part size deviations), and error correction (automatic correction of assembly errors). Currently, these are only available in high-end models with significant premiums:

Basic models without AI functions: No additional cost.

Basic AI functions (e.g., autonomous path optimization): 20% – 30% higher price than basic models (e.g., a $120,000 robot becomes approximately $144,000 – $156,000 with AI).

Advanced AI functions (e.g., autonomous multi-task planning, environmental adaptation): 40% – 60% higher price than basic models (e.g., a $120,000 robot becomes approximately $168,000 – $192,000 with advanced AI).

The cost of AI functions mainly comes from algorithm development and data training. Currently, only leading enterprises such as FANUC, ABB, and UBtech can provide mature solutions.

Hidden Costs Cannot Be Ignored: Installation, Training, and Ongoing Support

Most enterprises only focus on the “purchase price” of robots, but overlook “hidden costs” such as installation and integration, training, and maintenance. These costs often account for 50% – 150% of the purchase price and are critical to the Total Cost of Ownership (TCO):

Installation and System Integration: Costs May Double; Turnkey Solutions Are More Convenient

System integration is the core link for connecting robots to existing production lines (e.g., conveyors, machine tools, inspection equipment), with significant cost variations:

Traditional Integration (Step-by-Step Connection):

Installation and debugging fees: Approximately 30% – 50% of the robot purchase price (e.g., $60,000 – $100,000 for a $200,000 robot). For specialized equipment like thermometer visual labeling machines, additional debugging of vision-label alignment (to ensure label position accuracy within ±0.5mm) adds $8,000 – $12,000.

Facility modification fees: Include power upgrades (e.g., 380V industrial power for high-power robots, $10,000 – $30,000), compressed air systems (for pneumatic fixtures, $5,000 – $20,000), and safety fences (mandatory for industrial robots, $20,000 – $50,000).

Total hidden costs account for approximately 50% – 80% of the purchase price. Enterprises also need to coordinate multiple suppliers (robot manufacturers, integrators, facility modifiers), which may lead to responsibility shirking.

Turnkey Solutions (One-Stop Integration):Suppliers handle the entire process from solution design, equipment procurement, installation and debugging to acceptance. Costs are approximately 80% – 120% of the purchase price (e.g., a total cost of $160,000 – $240,000 for a $200,000 robot). For thermometer visual labeling lines, turnkey solutions also include integration with upstream thermometer assembly stations and downstream quality inspection modules, shortening deployment time by 40% compared to traditional integration.

Training Fees: Significant Differences Based on Skill Requirements (from Basic Operation to Programming)

Robots require professional personnel for operation and maintenance, and training costs increase with skill requirements:

Basic Operator Training: Covers startup/shutdown, daily inspection, and simple troubleshooting. Duration: 1 – 2 days. Cost: $500 – $1,500 per person (e.g., ABB’s basic operation course: $800 per person per day).

Programming Engineer Training: Covers robot program writing, trajectory optimization, and vision system debugging. For thermometer visual labeling machines, this includes training on adjusting vision parameters for different thermometer sizes—duration 4 – 6 days, cost $3,000 – $6,000 per person.

Customized Training: For enterprise-specific scenarios (e.g., setting process parameters for welding robots). Duration: Over 1 week. Cost: $5,000 – $10,000 per person.

It is recommended that enterprises train personnel at a ratio of “1 engineer + 3 – 5 operators”, with an initial total training cost of approximately $10,000 – $30,000.

Ongoing Support: 10% – 15% of the Purchase Price Annually to Ensure Long-Term Stable Operation

Post-purchase maintenance and software updates are important parts of long-term costs:

Annual Maintenance Services: Include regular inspections (once per quarter), spare parts replacement (e.g., motor bearings, sensors), and software version updates. For thermometer visual labeling machines, this includes calibration of vision cameras (to maintain labeling precision) and replacement of wear-resistant label rollers—annual cost approximately 12% – 18% of the purchase price (slightly higher than general industrial robots due to medical-grade precision requirements).

Emergency Repair Services: On-site repairs for unplanned downtime. One-time cost: $2,000 – $10,000 (domestic manufacturers: response time within 48 hours, cost $2,000 – $5,000; imported manufacturers: response time within 72 hours, cost $5,000 – $10,000).

Spare Parts Stockpiling: Key spare parts (e.g., servo motors, controllers) need to be stocked in advance. Cost: Approximately 5% – 10% of the purchase price (e.g., $10,000 – $20,000 for spare parts of a $200,000 robot) to avoid long-term downtime due to spare part shortages.

Customized vs. Off-the-Shelf Solutions: Balancing Cost and Flexibility

Enterprises need to choose between “customized” and “off-the-shelf solutions” when purchasing robots. The two have significant cost differences and are suitable for different scenarios:

Off-the-Shelf Solutions (Standard Models): Low Cost, Fast Deployment, Suitable for General Scenarios

Core Advantages: No additional engineering design required; model parameters (load, precision, working radius) are standardized for direct deployment (e.g., RO1 6-axis robot: installation and debugging can be completed within 1 – 2 days after unboxing).Cost Level: No premium on the basic purchase price; hidden costs (integration, training) are also lower (20% – 30% lower than customized solutions).Suitable Scenarios: General tasks (e.g., handling, assembly, quality inspection), small-to-medium batch production, cost-sensitive enterprises (e.g., small-to-medium electronics factories, hardware factories).

Customized Solutions: High Cost, Long Cycle, Suitable for Special Scenarios

Core Needs: Require customized mechanical structures (e.g., special fixtures, unique working radii), software functions (e.g., integration with enterprise-specific MES systems), or adaptation to special environments (e.g., high temperature, explosion-proof, aseptic conditions). For example, thermometer visual labeling machines for medical grade I devices need customized stainless steel frames (to meet GMP standards) and anti-static fixtures (to avoid damaging sensitive electronic thermometers)—these customizations increase costs by 40% – 60% compared to standard labeling robots.Cost Level: Total cost is 25% – 100% higher than off-the-shelf solutions, depending on complexity:

Light customization (e.g., customized fixtures, simple software integration): Cost increases by 25% – 50% (e.g., a $200,000 off-the-shelf robot becomes approximately $250,000 – $300,000 after customization).

Heavy customization (e.g., explosion-proof structures, aseptic design, dedicated AI algorithms): Cost increases by 50% – 100% (e.g., a $200,000 off-the-shelf robot becomes approximately $300,000 – $400,000 after customization).

Suitable Scenarios: Special industries (e.g., aseptic assembly in medical care, explosion-proof handling in chemical engineering), complex tasks (e.g., precision welding of aerospace parts), large-scale mass production enterprises with unique needs (e.g., large automotive manufacturers).

Cost Optimization Suggestions: Accurately Matching Needs to Avoid “Over-Investment”

Enterprises do not need to pursue the “most advanced” or “highest configuration” robots; instead, they should select cost-effective solutions based on their own needs. The following 4 steps can help:

Match Hardware Specifications to Tasks: Avoid “overloading” or “over-precision”. For example, if labeling standard electronic thermometers (requiring ±0.5mm label alignment), a 4-axis SCARA robot with basic 2D vision ($100,000 – $120,000) is sufficient—there is no need to purchase a 6-axis robot with 3D vision ($180,000+).

Prioritize Models with Built-In Core Functions: Choose robots with built-in vision systems (e.g., RO1) to save third-party integration costs. For thermometer visual labeling machines, this can reduce vision-related expenses by $15,000 – $30,000.

Evaluate the Long-Term Value of Turnkey Solutions: If the enterprise lacks professional integration teams, turnkey solutions (though 10% – 20% more expensive upfront) can avoid rework costs caused by misalignment (e.g., vision-label mismatch in thermometer production), reducing long-term losses.

Optimize Training and Maintenance Costs: Train 1 – 2 core engineers first, then let them train operators internally to cut external training fees by 30% – 50%. For maintenance, sign annual service agreements with manufacturers—this is 20% – 30% cheaper than paying for one-time repairs.