When production lines receive orders that shift from “100,000 identical parts” to “100 customized components with individual differences,” the “mass production dividend” of traditional manufacturing is facing unprecedented challenges. The surge in consumer demand for personalized, small-batch products stands in sharp contradiction to factories’ reliance on fixed processes and standardized equipment—a contradiction that flexible manufacturing is uniquely positioned to resolve. Its ultimate goal is not merely “multi-variety production,” but to “achieve the precision and efficiency of single-piece customization at the cost of mass production.” Behind this lies a complete reshaping of industrial production logic by intelligent technologies.

From “Rigidity” to “Flexibility”: The Growing Pains of Manufacturing Transformation

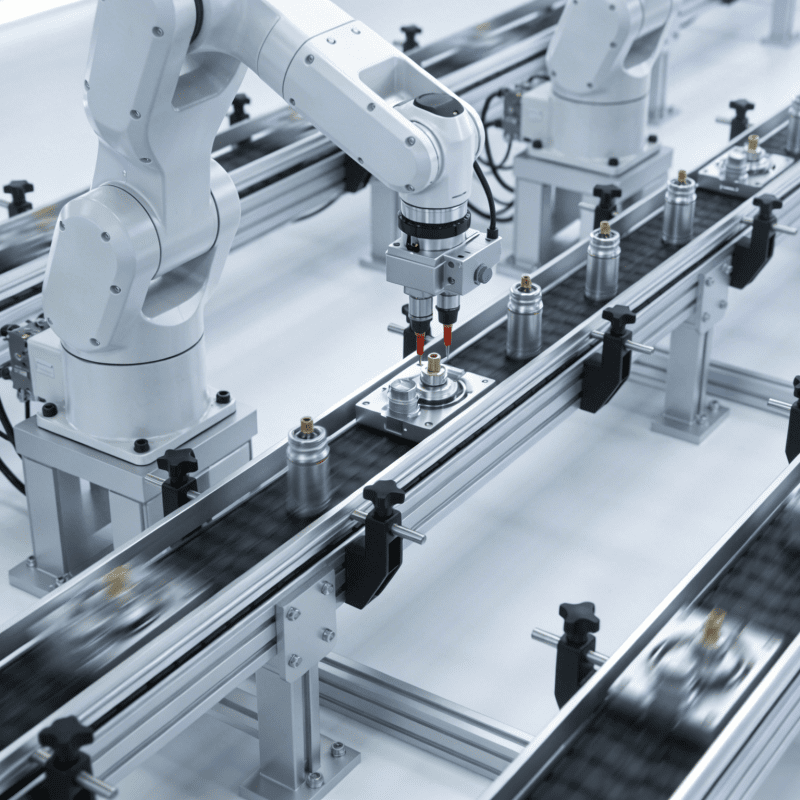

Traditional automated production lines are like precisely interlocking gears. Once programmed, they efficiently repeat a single task. However, this “rigidity” falters in the face of flexible demands: switching product models requires workers to manually adjust robotic arm trajectories, recalibrate sensor parameters, and modify assembly line rhythms—processes that can take hours or even days, often leading to quality fluctuations due to human error. Statistics from an auto parts factory show that when traditional lines switch products, the first-pass yield often plummets from 98% to 75%—a critical pain point in the shift to flexibility.

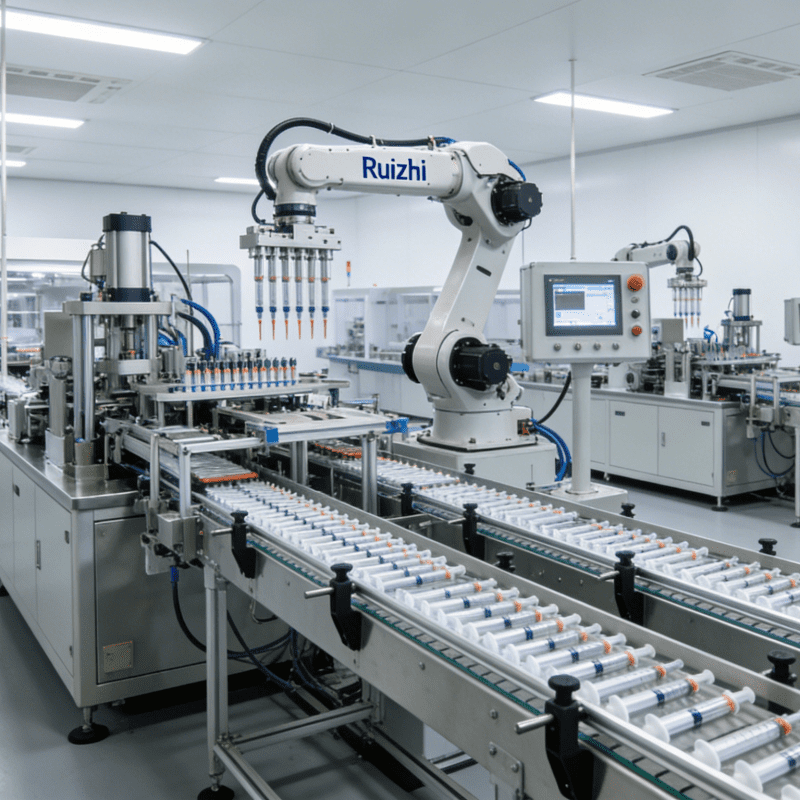

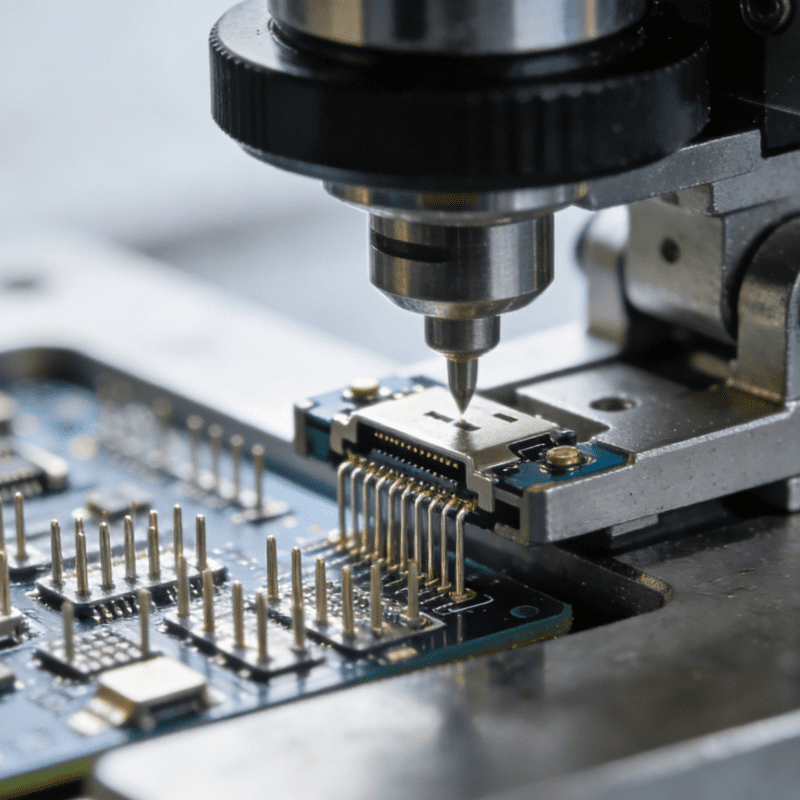

The core challenge of flexible manufacturing is endowing production systems with “dynamic adaptability.” This requires intelligent robots, sensors, and software systems to function not as isolated devices, but as an organic whole capable of real-time communication and autonomous collaboration: robots must automatically adjust gripping angles when incoming materials have minor size deviations; production lines must dynamically allocate equipment resources when order priorities change; and systems must self-reconfigure production paths during unexpected failures. This “unmanned adaptive capability,” far beyond the “rule-following” of traditional automation, demands deep integration of machine learning, computer vision, and industrial IoT technologies.

Digitalization: The Core Engine Activating Flexible Potential

“The essence of flexible manufacturing is endowing production systems with the wisdom of ‘autonomous decision-making,'” notes Gregor van Baars, an expert at the Netherlands Organisation for Applied Scientific Research (TNO). This highlights the key to transformation: digital technologies are not mere tools but grant factories a closed-loop “perceive-analyze-act” capability.

In practice, this “wisdom” is already showing promise. TNO’s “programming-free robot path planning system,” leveraging visual recognition and self-learning algorithms, enables robots to automatically scan part features and plan optimal gripping trajectories when encountering new products—no engineer-written code required. An electronics assembly plant using this technology reduced new product changeover time from 8 hours to 15 minutes and cut equipment idle rates by 60%. Critically, the system accumulates experience through continuous learning: when encountering similar parts, it automatically uses historical data to optimize movements, with precision improving as production volume increases.

Yet flexible manufacturing’s digitalization is not simply about “replacing humans with robots.” At a Dutch smart home factory, workers wear AR glasses that deliver real-time assembly instructions. Built-in image recognition compares current operations with standards, alerting users to deviations instantly. Meanwhile, smart sensors along the production line continuously collect data on equipment vibration and temperature, using algorithms to predict potential failures and trigger maintenance proactively. This “human-machine collaboration” retains humans’ flexible judgment while eliminating repetitive labor and errors through digital tools.

Beyond Technology: The Code to Implementing Flexible Manufacturing

Factories may invest in cutting-edge collaborative robots and industrial IoT platforms, only to still face “flexibilization failure”—often due to a “disconnect between technology and scenarios.” TNO research found that 70% of factory flexibilization projects stall not from technical shortcomings, but from neglecting “system integration” and “process reengineering.”

A truly flexible manufacturing system requires data across the entire chain: from order reception and design modeling to production scheduling and logistics. For example, a clothing brand’s flexible line converts real-time e-commerce order data directly into production parameters: the system automatically calculates fabric usage, generates cutting paths, assigns sewing tasks, and even dynamically adjusts workflows based on worker skill levels—shortening custom clothing production cycles from 15 days to 3 days. This relies on deep collaboration between ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), and PLM (Product Lifecycle Management), rather than isolated “smart islands” of single devices.

As van Baars emphasizes: “Flexible manufacturing is not a ‘problem solved by buying one robot.’ It requires redefining the relationships between ‘people, machines, materials, methods, and environment’ in production processes.” Only when technology is truly embedded in daily factory operations—from management decision systems to frontline workers’ habits—can flexibilization transition from “laboratory ” to “workshop normality.”

Conclusion: Flexible Manufacturing Reshapes the Future of Industry

The revolutionary significance of flexible manufacturing extends far beyond improving efficiency. It is rewriting manufacturing competition rules: small-batch, multi-variety production is no longer a “cost burden” but a competitive edge for rapid market response; factories thrive not on “scale effects” but “agility.” When a single line can produce both smartphone casings and medical device parts, and factories can meet 100,000-unit orders and 10-unit custom requests at the same cost, manufacturing will truly enter an intelligent era of “production on demand.”

The deeper value of this transformation lies in unleashing human creativity. As machines take over repetitive adjustments, calibrations, and inspections, workers evolve from “production line appendages” to “production system decision-makers”—focusing on optimizing processes, resolving anomalies, and designing innovative production schemes rather than mechanically executing instructions. This may be flexible manufacturing’s ultimate goal: letting technology serve human value, not the other way around.

In a future dominated by personalized demand, flexible manufacturing is more than a production method—it is manufacturing’s ability to thrive amid uncertainty. Its widespread adoption will drive industrial production from “large-scale replication” to “precision creation,” ultimately reshaping the entire manufacturing ecosystem and landscape.

Recommend some well-known custom factories for chain hoist automatic assembly lines.

What details need to be paid attention to when customizing a chain hoist automatic assembly line?