Every time you pick up a smartphone, start a car, or use a kitchen appliance, you’re holding the end result of a manufacturing marvel: the work of assembly machines. These systems aren’t just metal and code—they’re the engine that turns raw components (a screw, a microchip, a metal frame) into products we rely on daily. Far beyond “automating manual work,” assembly machines define how efficiently, precisely, and scalably modern factories operate. But what exactly is an assembly machine? How does it differ across industries? And how is it evolving to meet the demands of smart manufacturing? Let’s break it down.

At Its Core: What Is an Assembly Machine?

An assembly machine is a specialized, purpose-built system designed to perform repeatable, controlled operations that join individual components into a finished product or sub-assembly. Unlike human workers—who tire, vary in precision, or struggle with repetitive tasks—assembly machines excel at consistency, speed, and accuracy tailored to the product’s needs.

Its core mission is simple: eliminate friction in “putting things together.” For example:

A tiny assembly machine might fasten 500 micro-screws to a laptop’s circuit board in an hour (a task that would take a human 4+ hours, with far more errors).

A large robotic assembly machine could lift a 200kg car engine and align it with the chassis, with a margin of error under 0.1mm (impossible for manual labor alone).

In short, it’s the bridge between “parts” and “products”—turning chaos (piles of components) into order (market-ready goods).

Key Functions: What Do Assembly Machines Actually Do?

While assembly machines vary widely in size and complexity, they all perform four core functions to keep production on track:

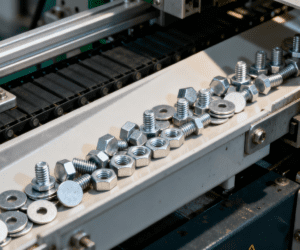

- Component Handling: Getting Parts Where They Need to Be

Before assembly can start, parts must be retrieved, sorted, and positioned correctly. Assembly machines use tools like vibrating feeders (which sort tiny parts like nuts or washers and feed them one-by-one to the assembly station—critical for electronics manufacturing), robotic grippers (which pick up irregularly shaped components like plastic casings or metal brackets and place them in exact positions; some use vacuum suction for delicate parts like phone screens, while others use mechanical claws for heavy items like car doors), and conveyor systems (which move partially assembled products between stations—e.g., carrying a toaster chassis from the “motor installation” station to the “cord attachment” station).

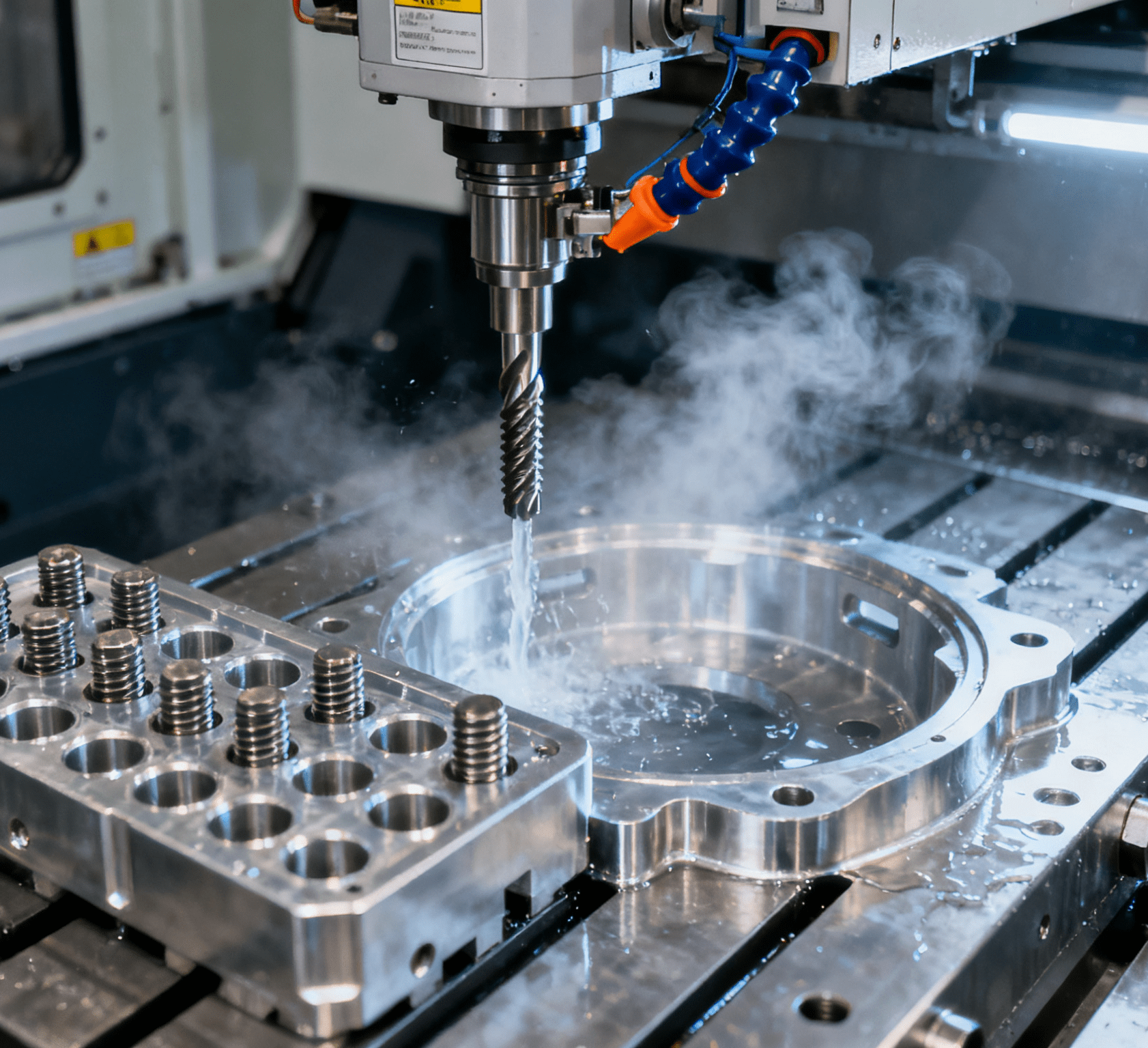

- Joining Operations: Securing Components Together

This is the “assembly” in assembly machines—permanently or temporarily connecting parts using methods tailored to the material and product. Common techniques include mechanical fastening (like screwing, bolting, or riveting; an assembly machine might use torque-controlled screwdrivers to attach a phone’s back cover, ensuring screws are tight but not stripped), welding or bonding (for metal parts, laser welding robots join aerospace components; for plastic parts, ultrasonic welding seals water bottle caps), and press-fitting (for interference fits, like pressing a bearing into a gearbox, where the machine applies precise force to avoid damaging either part).

- Quality Inspection: Catching Errors Before They Reach Customers

Modern assembly machines don’t just build—they verify. Integrated sensors and vision systems ensure every step meets standards: vision sensors use cameras to check for missing parts (e.g., “did the machine add all 4 screws to the laptop base?”) or defects (e.g., “is the phone screen cracked?”), force or torque sensors measure pressure or tension (e.g., “is the bolt tightened to 5 N·m, as required?”), and dimensional scanners confirm parts are aligned correctly (e.g., “is the car door flush with the body, within 0.5mm?”).

- Process Integration: Working With the Rest of the Factory

Assembly machines don’t operate in a vacuum—they connect to other factory systems to create a seamless flow. For example, if a feeder runs low on screws, the machine signals the inventory system to restock; once a product is assembled, the machine sends it to the packaging station via conveyor; and it shares production data (like “how many units did we build in an hour?” or “how many defects were found?”) to the factory’s central dashboard for real-time monitoring.

The Building Blocks: Key Components of an Assembly Machine

An assembly machine’s performance depends on its modular, integrated parts—each playing a critical role in turning components into finished products.

First is the mechanical structure—the “body” of the machine that provides stability and movement. This includes frames (from compact tabletops for small electronics to large floor-mounted systems for heavy parts), robotic arms (like 6-axis arms that rotate and position parts with micron-level accuracy), and conveyors or gantries (e.g., a gantry robot—an arm on a track—that moves across a car assembly line to reach different stations).

Next is the control system—the “brain” that dictates how the machine operates. Most modern assembly machines use a Programmable Logic Controller (PLC), a digital computer that runs pre-programmed instructions to control movement, timing, and task sequence. For instance, a PLC might tell a screwdriving machine to “tighten 4 screws, 3 N·m each, 2 seconds apart.”

Operators interact with the machine via a Human-Machine Interface (HMI)—the “control panel” that typically includes a touchscreen or physical buttons. This lets workers adjust settings (like increasing a machine’s speed from 10 units/hour to 12), monitor progress, or troubleshoot issues (e.g., viewing a alert if a part feeder is empty).

Then there are sensing and inspection modules—the machine’s “eyes and hands” for quality control. These include the vision sensors, force/torque sensors, and dimensional scanners mentioned earlier; a common example is a vision sensor that rejects a phone case with a scratch before it moves to the next assembly step.

Finally, the power system supplies the energy needed to run the machine. Electric motors are used for precision tasks (like small electronics assembly, where consistent speed is key), while hydraulic or pneumatic systems power heavy-duty operations (like press-fitting metal parts in automotive manufacturing, where high force is required).

Types of Assembly Machines: Tailored to Every Manufacturing Need

Assembly machines aren’t one-size-fits-all—they’re designed to match production volume, product complexity, and industry requirements. Here are the four most common types:

- Manual-Assist Assembly Machines

Best for small-batch, custom production (e.g., custom medical devices, prototype parts), these machines rely on humans to handle complex tasks (like loading delicate components) while automating repetitive steps. For example, a worker might place a custom circuit board into a fixture; the machine then automatically solders 10 connections and checks for defects—reducing manual effort without requiring full automation.

- Semi-Automatic Assembly Machines

Ideal for mid-volume production (e.g., small appliances, industrial tools), semi-automatic machines use one or two workers to support operations—feeding parts, swapping fixtures, or loading materials—while the machine handles most assembly and inspection. In a toaster factory, for instance, a worker loads a heating element into the chassis; the machine then attaches wires, tests the heating function, and sends the chassis to the next station.

- Fully Automatic Assembly Machines

Built for high-volume, repetitive production (e.g., smartphones, EV batteries, soda cans), these machines run 24/7 with minimal human intervention. Parts are fed automatically, assembly is done by robots, and defects are rejected without operator input. A prime example is a fully automatic EV battery assembly line: robots pick battery cells, stack them into modules, weld connections, test for leaks, and package the module—all in 60 seconds per unit.

- Collaborative Assembly Machines (Cobots)

Designed for tasks that need both human judgment and machine precision (e.g., complex electronics, custom furniture), cobots work with humans (not replace them). Equipped with safety sensors that stop movement if a human gets too close, they complement human skills: a cobot might hold a heavy laptop shell while a worker solders a delicate wire, keeping the shell steady (avoiding hand tremors) and pausing if the worker’s hand moves too close.

Where Assembly Machines Shine: Industry Applications

Assembly machines are everywhere in manufacturing—adapted to the unique needs of each sector:

Automotive: Heavy-duty robotic assembly machines build engines, transmissions, and EV batteries. Tesla’s Gigafactories, for example, use fully automatic machines to stack battery cells into packs with a precision of 0.02mm—critical for EV performance and safety.

Electronics: Compact, high-speed machines assemble smartphones, wearables, and IoT devices. A machine building AirPods can solder 1,000 microchips per minute and check for audio defects in real time, ensuring consistent quality across millions of units.

Medical Devices: Sterile, regulated assembly machines create syringes, insulin pens, and surgical tools. A machine assembling pacemakers uses cleanroom-compatible materials and vision sensors to detect even tiny defects (like a 0.1mm scratch on a wire)—meeting strict healthcare standards.

Consumer Goods: Versatile machines build everything from toothbrushes to refrigerators. A semi-automatic toothbrush machine attaches bristles to handles, trims excess bristle length, and packages the final product—streamlining production for everyday items.

The Future of Assembly Machines: Smart, Flexible, and Connected

As manufacturing shifts to Industry 4.0 (smart, data-driven factories), assembly machines are evolving beyond “automation” to “intelligence.” Here are the key trends shaping their future:

- IoT Integration: Machines That “Talk”

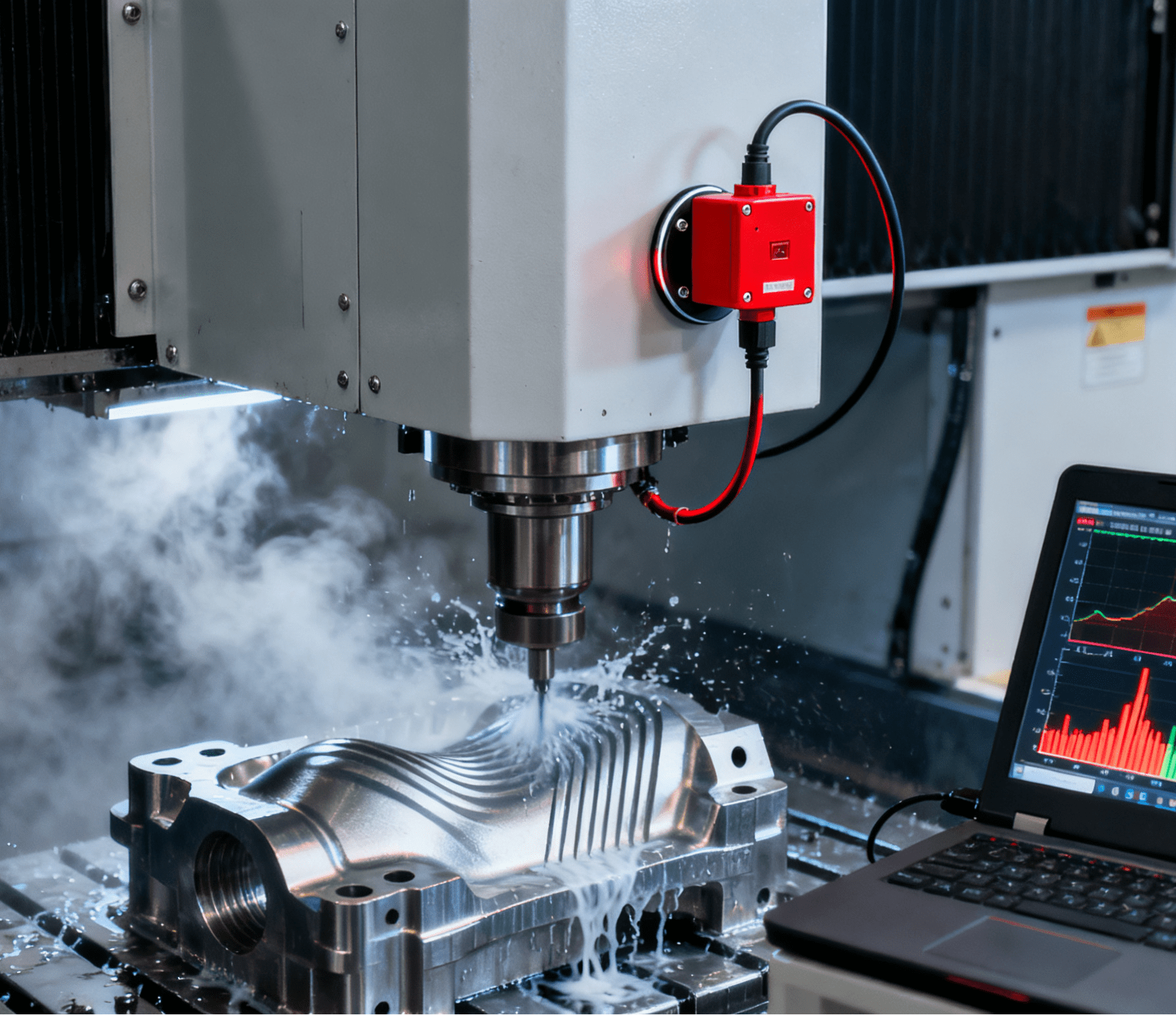

Sensors embedded in assembly machines collect real-time data (like vibration, temperature, or cycle time) and send it to cloud platforms. This enables predictive maintenance—if a sensor detects unusual vibration in a robotic arm, it alerts technicians to replace a worn bearing before the arm breaks, cutting unplanned downtime by 30–50%. It also allows remote monitoring: factory managers can check a machine’s performance from a phone or laptop, even when off-site.

- AI-Powered Optimization: Machines That “Learn”

Artificial intelligence analyzes production data to make real-time adjustments. For example, if an AI system notices a spike in loose screws, it automatically tweaks the machine’s torque settings (no human input needed). AI can also predict bottlenecks—like “the feeder will run out of screws in 10 minutes”—and reroute parts to avoid delays, keeping production smooth.

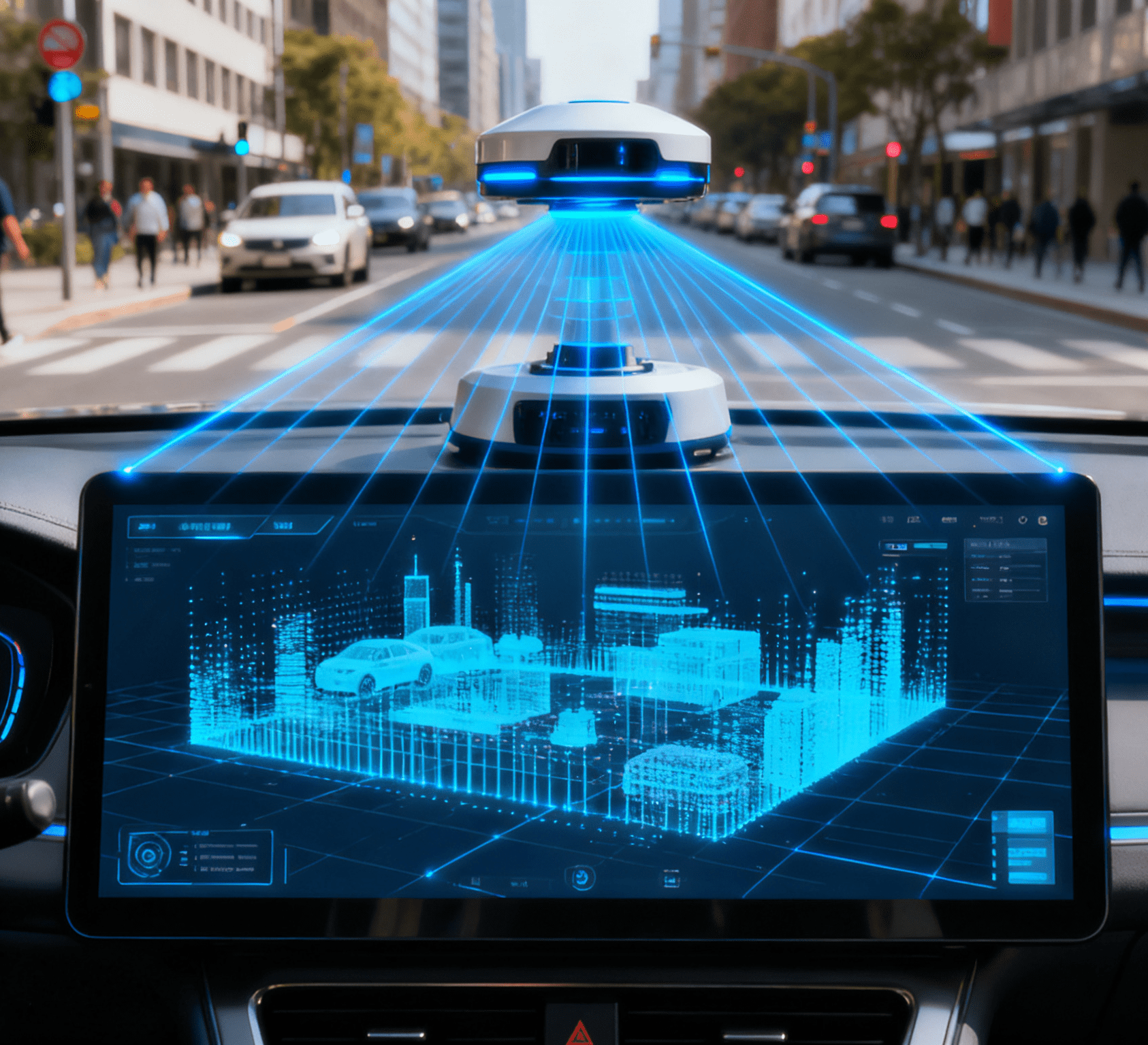

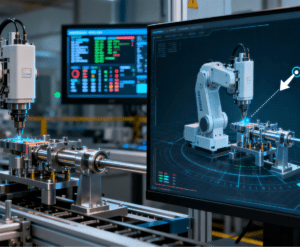

- Digital Twins: Machines That Have “Virtual Copies”

A digital twin is a 3D virtual replica of an assembly machine. Manufacturers use these twins to test new processes (e.g., “what if we change the welding speed?”) in a virtual space, without disrupting physical production. They also use twins to troubleshoot issues—like figuring out why a machine is rejecting 5% of parts—by simulating different fixes before applying them to the real machine.

- Flexible Automation: Machines That “Adapt”

As consumers demand more personalized products (e.g., custom-colored phones, made-to-order furniture), assembly machines are becoming modular. A single machine can now assemble both wireless earbuds and smartwatches by swapping out fixtures and updating its PLC program—taking just 1 hour to reconfigure, instead of days. Cobots, too, can switch between tasks (from screwdriving to packing) with minimal adjustments, making small-batch, high-variety production feasible.

Why Assembly Machines Matter: More Than Just “Productivity Tools”

Assembly machines aren’t just about making more products faster—they’re about redefining what’s possible in manufacturing. They reduce waste by catching defects early (saving materials and money), protect workers by taking over dangerous or repetitive tasks (like lifting heavy parts or working with high heat), and enable innovation: without assembly machines, complex products like EVs, smartphones, or pacemakers would be too slow or expensive to build at scale.

In a world where “faster, better, cheaper” is the norm, assembly machines are the unsung heroes. They turn design ideas into tangible products, small businesses into global brands, and manual factories into smart, efficient operations.

Wrapping Up

An assembly machine is more than a piece of equipment—it’s the backbone of modern manufacturing. From a tiny screwdriving machine building phones to a massive robotic line assembling cars, it’s the force that turns components into products, and products into progress. As it evolves to be smarter, more flexible, and more connected, it will keep driving manufacturing forward—making the products of tomorrow possible, today.

Assembly line for mass production by artificial intelligence