Table of Contents

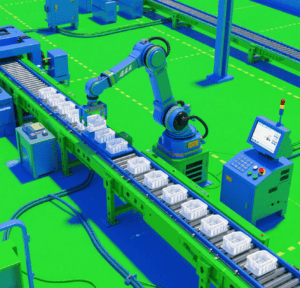

Toggle4-Axis Robotic Injection Molding Part Removal System: Revolutionizing Post-Molding Automation

In the high-volume landscape of injection molding, traditional part removal methods—ranging from manual extraction to basic mechanical arms—face critical limitations: slow cycle times (15–30 seconds per part), inconsistent handling (±0.5mm positioning errors), and high risk of part damage. The 4-Axis Robotic Injection Molding Part Removal System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive gripping to streamline post-molding operations in automotive, electronics, and medical device manufacturing.

I. Core Technical Architecture: Speed Meets Precision

The system’s modular design synergizes robotic agility with intelligent control, comprising three interdependent subsystems:

1. High-Speed 4-Axis Robotic Manipulation

Powered by SCARA robots (e.g., Epson LS6, Yamaha YK-XG), the system delivers:

- Planar Motion Efficiency: Achieves part removal speeds of 120–180 parts per hour with ±0.02mm repeatability, 3–5x faster than traditional systems;

- Adaptive Payload Handling: Lightweight carbon fiber arms handle 0.1–5kg molded parts (including end-effectors), balancing speed with stability for delicate components;

- Compact Work Envelope: Horizontal reach up to 800mm, ideal for integration with standard injection molding machines (50–500 ton clamping force).

2. Vision-Guided Part Localization

A dual-camera vision setup ensures sub-millimeter accuracy:

- Overhead 2D Camera: 12MP resolution with telecentric lenses maps part positions on mold ejector plates, correcting ±10mm deviations using YOLOv8-based feature recognition;

- Infrared Thermal Imaging: Detects residual heat patterns (temperature variance >5°C) to avoid handling undercooled or overheated parts, critical for dimensional stability;

- Real-time Defect Inspection: AI algorithms identify flash, warpage, or surface defects with 99.7% accuracy before part removal, reducing downstream rework.

3. Adaptive Gripping & Deposition System

End-effectors combine precision mechanics with smart sensing:

- Multi-Config Gripper Tooling: Pneumatic vacuum cups for smooth-surface parts (e.g., automotive trim) and mechanical clamps for complex geometries (e.g., connectors), with force control (0.5–10N) to prevent deformation;

- Quick-Change Tooling: Swaps between gripper modules in <15 seconds using standardized interfaces, supporting rapid adaptation to new mold designs;

- Anti-Static Design: Conductive materials and ionizing bars for ESD-sensitive electronics components (surface potential <100V).

II. Industrial Applications: From Micro-Molding to Mass Production

1. Automotive Component Extraction

- Bumper & Trim Removal: Vacuum grippers handle 1–5kg plastic bumpers with ±0.1mm positional accuracy, enabling immediate robotic trimming of flash edges;

- Engine Component Demolding: Magnetic grippers extract metal-injected plastic (MIM) parts from high-temperature molds (up to 200°C), with heat-resistant coatings extending tool life by 50%.

Case Study: A German automotive supplier reduced part removal cycle time by 60% and increased mold utilization by 35% after deploying 30 systems, achieving 24/7 operation with 99.5% uptime.

2. Electronics & Consumer Devices

- Micro-Molded Connector Extraction: Piezoelectric microgrippers handle 0.1–1g connectors with ±0.05mm accuracy, preventing pin deformation in high-density connectors;

- Wearable Device Housing Removal: Vision-guided deposition into anti-static trays, with ESD protection meeting IEC 61340 standards for smartwatch casings.

3. Medical Device Manufacturing

- Sterile Syringe Component Removal: 316L stainless steel grippers and ISO 8 cleanroom compatibility for medical-grade parts, with traceability software recording each part’s removal timestamp;

- Microfluidic Chip Demolding: Force control (±0.1N) ensures damage-free extraction of 0.5mm-thick PDMS chips for diagnostic devices.

III. Competitive Advantages Over Traditional Systems

| Performance Metric | Manual/Semi-Automated | 4-Axis Robotic System |

| Removal Cycle Time | 15–30 seconds | 3–5 seconds |

| Positioning Accuracy | ±0.5mm | ±0.02mm (X/Y) |

| Defect Rate (handling) | 0.8–1.5% | <0.05% |

| Heat Resistance | <80°C | Up to 200°C (heat-treated parts) |

| Labor Requirement (per line) | 2–3 operators | 1 supervisor (remote monitoring) |

IV. Future Innovations

AI-Driven Autonomous Operation

- ML models analyze 100,000+ removal cycles to predict optimal grip points for new part designs, reducing setup time by 70%.

5G-Enabled Edge Computing

- Real-time data streaming from force sensors and vision systems enables millisecond-level collision avoidance in multi-robot cells.

Sustainable Design Paradigms

- Regenerative drives recover 30% of braking energy, and biodegradable gripper materials reduce waste in disposable medical device production.

Conclusion

The 4-Axis Robotic Injection Molding Part Removal System represents a paradigm shift in post-molding automation, addressing the critical needs for speed, precision, and reliability in modern manufacturing. By eliminating manual inefficiencies and enabling data-driven quality control, it becomes an indispensable asset in smart factory ecosystems. As Industry 4.0 progresses, these systems will evolve into self-optimizing cyber-physical systems, ensuring every molded part is removed with unprecedented efficiency while adapting to the ever-growing complexity of injection molding applications.

#4-Axis Robotic Injection Molding #Vision-Guided Part Removal System #Automated Molding Deposition Technology