Amid the vigorous development of high-end manufacturing, the accuracy of precision machining seems to have entered a “slow lane,” with its improvement speed falling short of expectations. What factors are holding it back? Let Aier Precision Machinery explore the reasons for you.

Hardware and Inspection Bottlenecks: Equipment Limitations and Lagging Inspection Technology

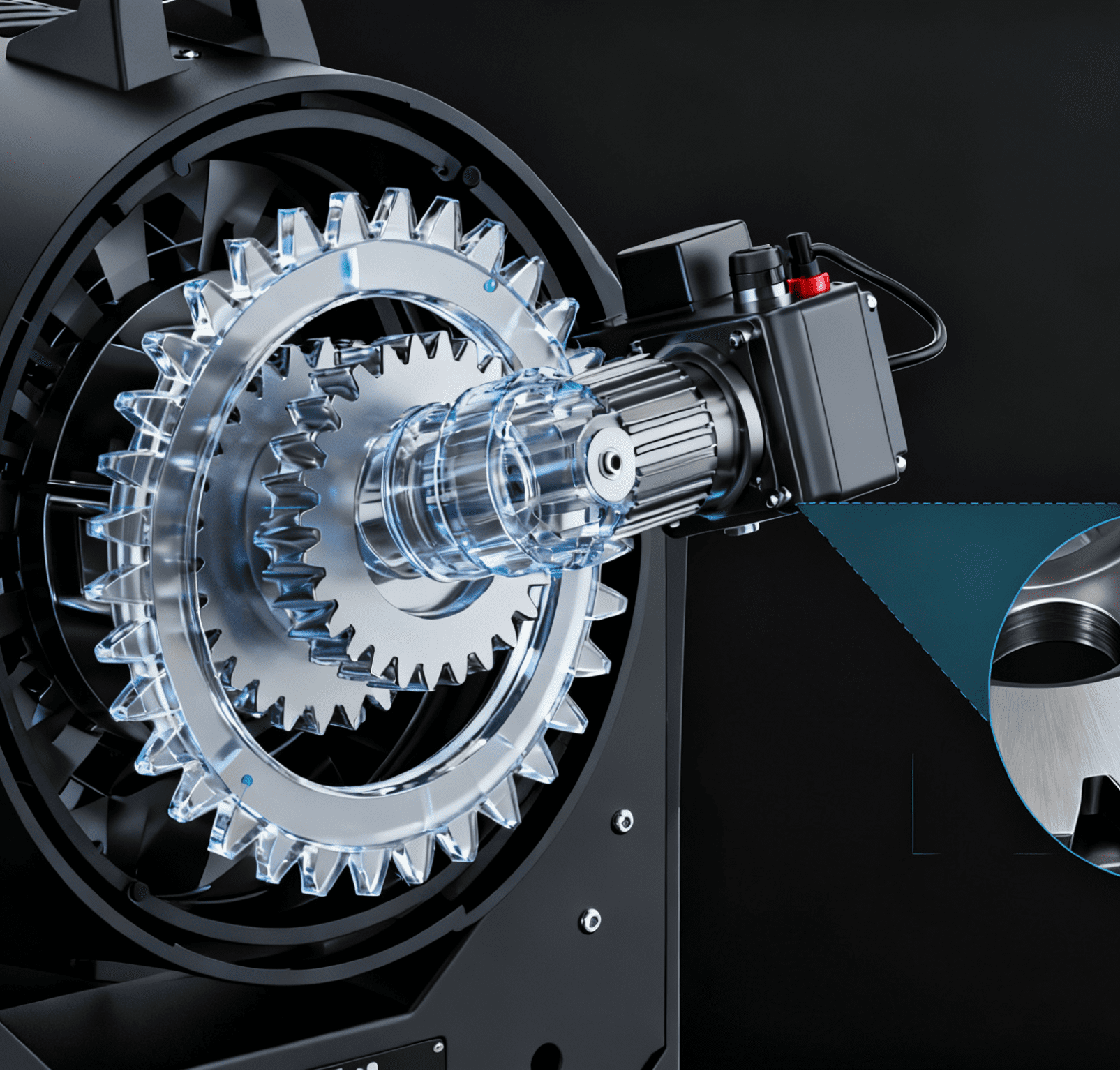

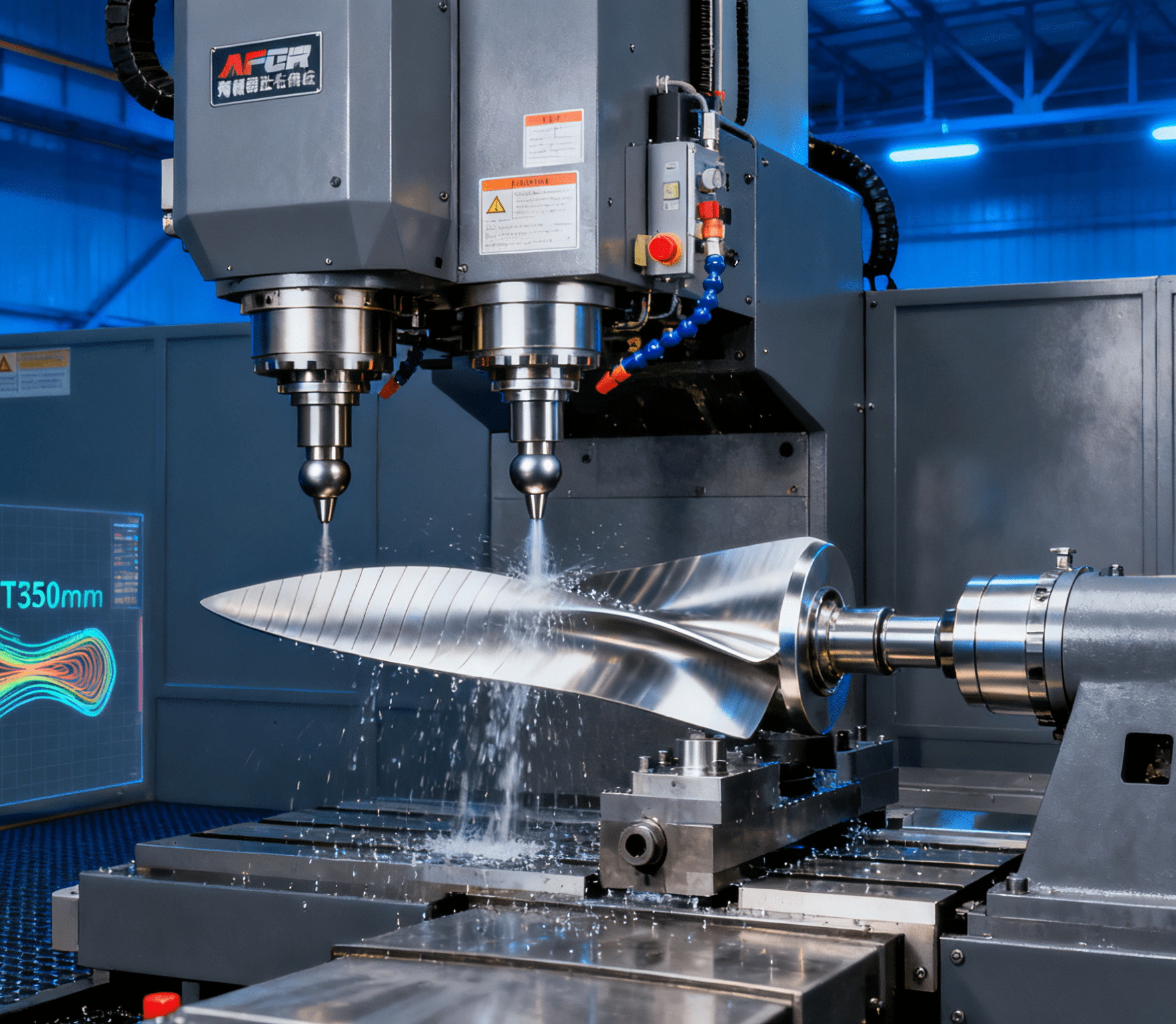

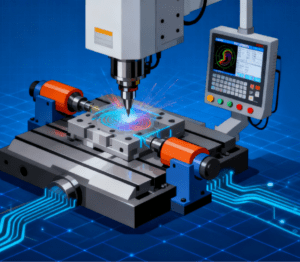

First, the inherent limitations of processing equipment are a major “obstacle.” Taking CNC precision machining as an example, although Computer Numerical Control (CNC) machine tools have been widely used and made significant contributions to precision machining, they also face “growing pains.” Through practical experience, Aier Precision Machinery has found that even minor wear or gap changes in the mechanical transmission components of CNC machine tools will be amplified like a “butterfly effect” during processing, leading to deviations in machining accuracy. Furthermore, the positioning accuracy of machine tools is limited by the accuracy of sensors. Although current sensor technology is constantly advancing, achieving high-precision real-time and accurate feedback still requires overcoming many challenges, which undoubtedly restricts the pace of rapid improvement in machining accuracy.

In addition, the relatively slow development of precision inspection technology has plunged accuracy improvement into a “blind zone.” Without precise inspection methods, it is impossible to accurately determine the actual level of machining accuracy, and subsequent improvements become impossible. Existing inspection equipment often struggles when measuring the accuracy of workpieces with micro-sized dimensions or complex shapes, making it difficult to promptly identify and resolve accuracy issues during the machining process.

Process Constraints: Material Properties and Skill Threshold for Operators

Moreover, material properties pose a challenge to precision machining. Different materials exhibit varying deformation and stress release behaviors during processing. For instance, titanium alloy, commonly used in the aerospace field, has high strength and good heat resistance, but it is prone to generating residual stress during machining. This residual stress can cause subtle deformation of the workpiece in subsequent processes, undermining the existing accuracy achievements. When dealing with such difficult-to-process materials, Aier Precision Machinery needs to conduct repeated tests and optimize process parameters, which consumes a great deal of time and effort to minimize accuracy losses—greatly slowing down the overall process of accuracy improvement.

The skills and experience of operators are also crucial. CNC precision machining is not a simple “one-click operation”; it requires operators to have a deep understanding of processes and a thorough grasp of machine tool performance. New operators may cause a significant decline in machining accuracy due to improper parameter settings or incorrect tool selection. Aier Precision Machinery is well aware that cultivating a mature precision machining operator requires years of practical experience accumulation. During this period, accuracy fluctuations caused by human factors are inevitable, affecting the stability and continuity of accuracy improvement.

Environmental Adaptation Challenges: Costs and Fluctuation Risks of High-Demand Processing Environments

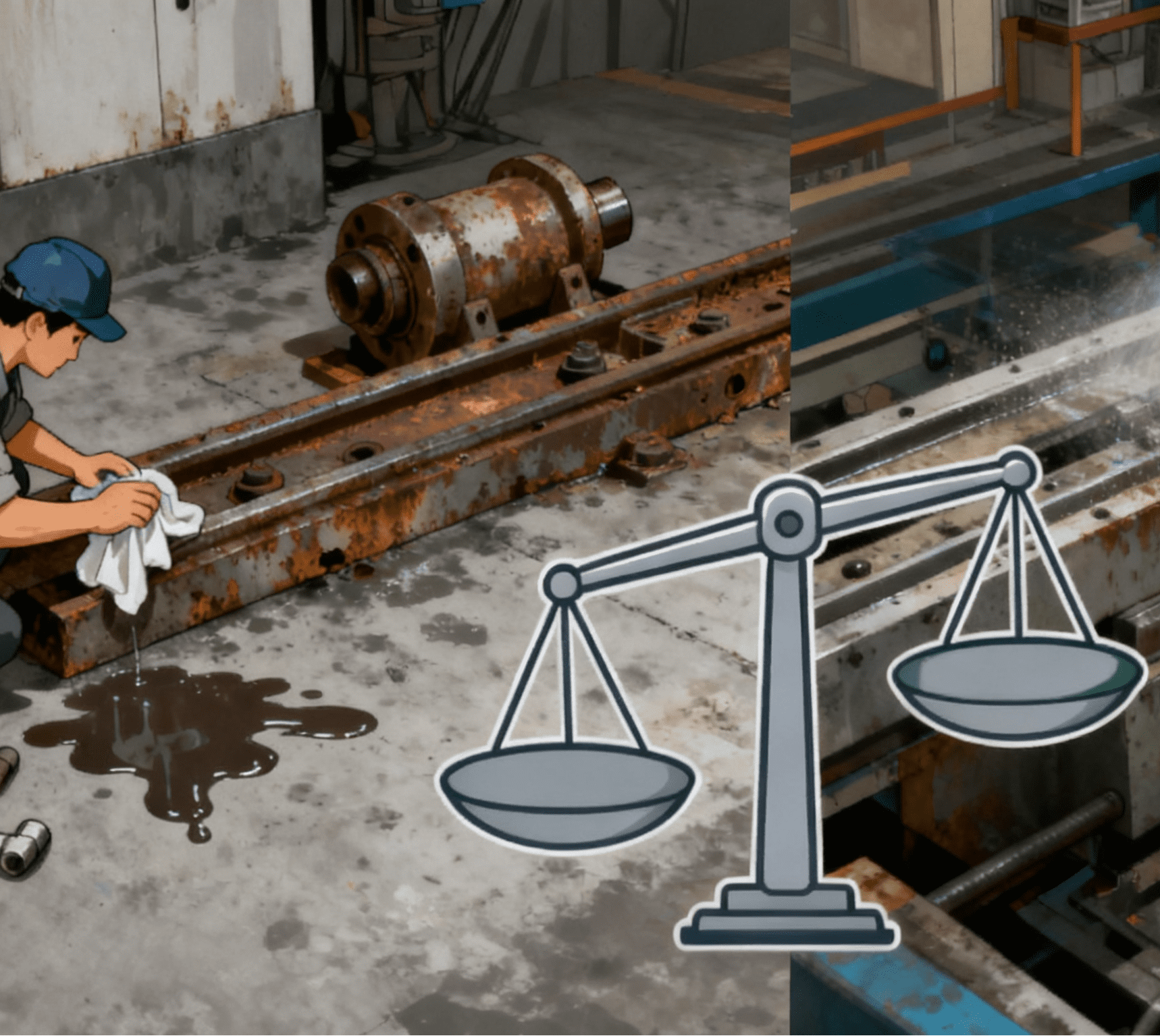

The nearly harsh requirements for the processing environment also contribute to the slow improvement of accuracy. Even tiny temperature changes or vibration interference can be “captured” by precision machining. In ultra-precision machining workshops, the temperature must be controlled within an extremely narrow range; even vibrations caused by personnel movement or equipment operation need to be eliminated using professional shock absorption devices. Aier Precision Machinery invests significant costs to create such an environment, but even a slight oversight can lead to environmental fluctuations that hinder the improvement of accuracy.

Despite facing numerous difficulties, Aier Precision Machinery has never stopped exploring. On one hand, it increases R&D investment to upgrade equipment and optimize processes; on the other hand, it strengthens talent cultivation to improve the skills of operators. At the same time, it collaborates with scientific research institutions to tackle key issues in inspection technology, striving to break the deadlock of slow improvement in precision machining accuracy and promote high-end manufacturing to reach new heights.

Assembly line for mass production by artificial intelligence