In fields such as auto parts, home appliance manufacturing, and medical equipment, springs serve as core basic components. The “last mile” of their production process—finished product arrangement and tray loading—has long relied on manual operations. However, manual arrangement is not only inefficient (with a daily processing capacity of less than 5,000 pieces per person) and prone to high error rates (misalignment and missing rates exceeding 3%), but also faces challenges such as rising labor costs year by year and difficulty in recruiting skilled workers. With the accelerated upgrading of manufacturing automation, the Automatic Spring Tray Arrangement Equipment has emerged as a key device to solve the pain points of spring arrangement and close the production loop.

- Why Has Automatic Spring Tray Arrangement Equipment Become a “Necessity”? Analyzing the Core Pain Points of the Industry

After production, springs need to be neatly arranged in trays by specification and direction (e.g., compression springs with a diameter of 5-20mm require directional arrangement to avoid directional confusion during subsequent assembly). Traditional manual operations have three core problems:

Efficiency Bottleneck: Manual arrangement requires sorting and positioning one by one. Filling a single tray (holding 200-500 springs) takes 15-20 minutes, while automated equipment can reduce this time to 3-5 minutes, increasing efficiency by 3-5 times.

Out-of-Control Precision: Manual arrangement is susceptible to fatigue and visual errors, leading to reversed spring directions and uneven gaps. Subsequent assembly requires rework, adding 15% of invalid costs.

Cost Pressure: Calculated at an average monthly salary of 6,000 yuan per person, a spring production line needs 2-3 arrangement workers, resulting in an annual labor cost of over 150,000 yuan. In contrast, automated equipment enables “one person to monitor multiple lines,” reducing annual costs by more than 60%.

Especially in high-precision scenarios such as automotive shock absorber springs and home appliance temperature control springs, manual arrangement can no longer meet the production requirements of “zero error and high continuity.” Therefore, automatic spring tray arrangement equipment has become an inevitable choice for enterprises to break through production capacity bottlenecks.

- Core Functions of Automatic Spring Tray Arrangement Equipment: From “Manual Dependence” to “Intelligent Closed Loop”

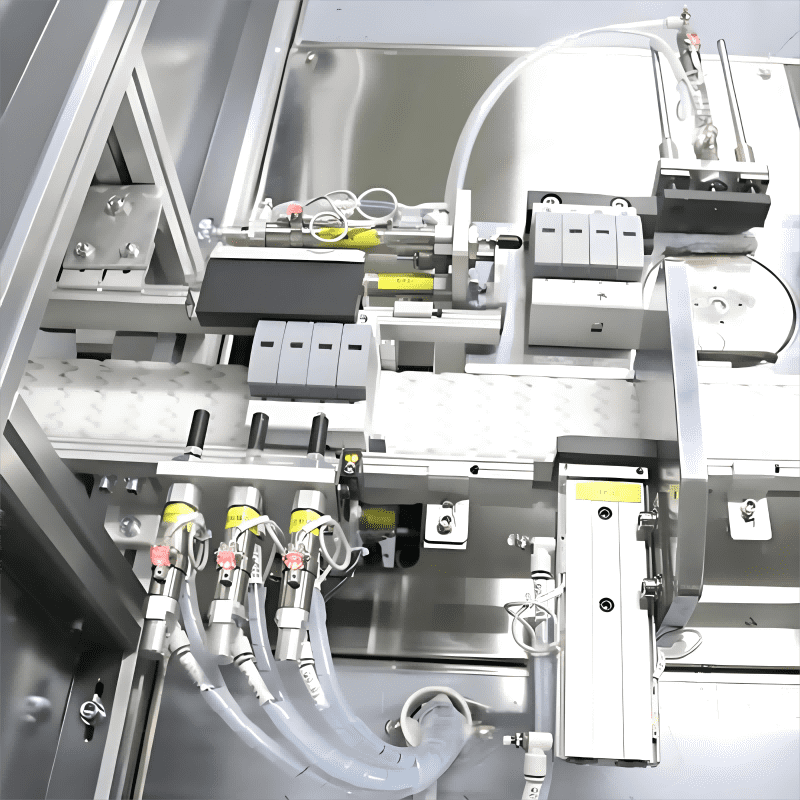

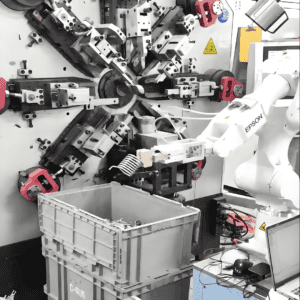

High-quality automatic spring tray arrangement equipment is not simply a “machine replacing manual labor,” but achieves “high efficiency, precision, and continuity” in spring arrangement through full-process automation of “feeding → identification → arrangement → tray loading → tray changing.” Its core functions can be summarized into four modules:

- Automatic Feeding: Adapting to Multi-Specification Springs and Avoiding Jamming

The equipment realizes automatic spring feeding through a vibratory bowl or conveyor belt, equipped with an adjustable-speed feeding channel (width adjustable from 5-30mm). It is compatible with different types of springs such as compression springs, extension springs, and torsion springs, as well as multi-specification products with diameters of 2-50mm and lengths of 5-100mm. A built-in “anti-jamming sensor” automatically triggers reverse vibration when springs are stacked, controlling the jamming rate below 0.1%.

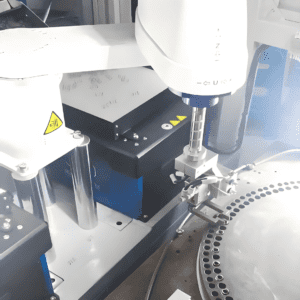

- Visual Positioning + Mechanical Arrangement: Precision up to ±0.1mm with Zero Misalignment

The equipment is equipped with an industrial camera (20-megapixel resolution) and an AI visual recognition system, which can real-time identify the direction and specification of springs (e.g., distinguishing the thickness difference between the two ends of a spring). Then, through a mechanical claw or push plate driven by a servo motor, the springs are neatly arranged in the tray according to preset spacing (e.g., 2mm gap) and direction. The arrangement precision can reach ±0.1mm, and the misalignment and missing rates are close to zero, meeting the assembly requirements of automotive-grade components.

- Automatic Tray Changing: 24/7 Continuous Production Without Interruption

The equipment is equipped with multiple tray stations (usually 2-4). When one tray is full, the system automatically moves an empty tray to the arrangement station and pushes the full tray to the discharge area, with a changeover time of only 10-15 seconds. Equipped with an automatic tray library (capable of storing 50-100 empty trays), it can realize 24-hour unmanned continuous production, solving the problem of production line interruption caused by manual tray changing.

- Data Traceability and Intelligent Monitoring: Connecting to MES System for Visual Management

The equipment has a built-in PLC control system and touch screen, which can real-time display data such as production quantity, arrangement precision, and equipment operation status. It also supports connection to the enterprise’s MES system via 4G/Ethernet, enabling “real-time upload of production data and remote push of abnormal alarms.” For example, when the spring specification does not match the tray, the system will automatically shut down and send an early warning to avoid batch errors.

Core Technical Highlights: The “Hard Strength” Supporting Stable Equipment Operation

The performance difference of automatic spring tray arrangement equipment essentially lies in the competition of core technologies. High-quality equipment usually has three technical highlights:

- Flexible Adaptation Technology: Rapid Changeover for Multi-Variety Orders

In response to the “multi-variety, small-batch” order characteristics of the manufacturing industry, the equipment supports “parameterized changeover”—by inputting parameters such as the diameter, length, and arrangement direction of new springs through the touch screen, the system automatically adjusts the feeding channel, visual recognition parameters, and arrangement spacing. The changeover time is shortened to 5-10 minutes (traditional manual adjustment takes 1-2 hours), meeting the production needs of enterprises for “one equipment handling multiple specifications.”

- Anti-Interference Mechanical Structure: Adapting to Complex Workshop Environments

The equipment adopts a dust-proof and oil-proof closed housing (protection level IP54), and key components (such as servo motors and bearings) use industrial-grade brands. It can operate stably in workshop environments with temperatures ranging from -10℃ to 45℃ and humidity ranging from 30% to 80%. At the same time, the arrangement platform is equipped with a shock absorption device to avoid the impact of workshop vibration on arrangement precision, with a comprehensive equipment failure rate of less than 0.5% per year.

- Energy-Saving Design: Reducing Long-Term Operating Costs

Compared with the combination of traditional manual labor and simple machinery, automatic spring tray arrangement equipment has more advantages in energy consumption. A single device usually has a power of 1.5-3kW and a daily power consumption of about 36-72 kWh. In contrast, manual arrangement requires supporting equipment such as lighting and fans, resulting in higher energy consumption. Some high-end equipment also supports an “intermittent operation mode,” which automatically enters a low-power state when there is no spring feeding, further reducing energy consumption.

Key Factors for Enterprise Selection: 4 Dimensions to Avoid “Adaptation Traps”

Many enterprises find that “the equipment does not match production” after purchasing automatic spring tray arrangement equipment—such as inability to be compatible with their own spring specifications, high failure rates, and slow after-sales response. When selecting equipment, focus should be placed on the following four dimensions:

- Specification Adaptability: Clarify the “Maximum/Minimum Compatibility Range”

Before purchasing, provide the manufacturer with detailed spring parameters (diameter, length, weight, type) and confirm whether the equipment’s compatibility range covers its own products. For example, to produce large springs with a diameter of more than 30mm, it is necessary to select equipment equipped with extended mechanical claws and large-size trays; to produce micro-springs (diameter 2-5mm), focus on the resolution of the visual recognition system (required to be ≥20 megapixels).

- Stability: Prioritize Manufacturers with “Industry Cases”

Request the manufacturer to provide application cases in the same industry (such as usage reports from automotive spring manufacturers) to understand the actual operation stability of the equipment (e.g., daily operation duration, failure rate). At the same time, check the brands of core components (e.g., servo motors from Panasonic, visual systems from Keyence) to avoid frequent maintenance in the later stage due to low-quality components.

- After-Sales Service: Focus on “Full-Cycle Support Capability”

After-sales service of automated equipment is crucial. Confirm whether the manufacturer provides: ① On-site installation and commissioning (to avoid precision deviation caused by self-installation by the enterprise); ② Operator training (to ensure workers can skillfully adjust parameters and handle simple faults); ③ Warranty period (at least 1 year of free warranty, 3 years of warranty for core components is recommended); ④ 24-hour remote technical support (to deal with sudden faults).

- Digital Adaptability: Whether “Future Upgrades” Are Supported

If the enterprise plans to build an intelligent factory in the future, select equipment that supports data connection—confirm whether the equipment has OPC UA protocol and Ethernet interface, and can link with MES and ERP systems to realize full-process traceability of production data. Avoid purchasing “isolated equipment,” which may require additional transformation during later digital upgrading.

Application Case: The Efficiency Upgrade Journey of a Domestic Automotive Spring Manufacturer

A domestic automotive spring manufacturer (specializing in shock absorber springs and clutch springs) once faced three major challenges: low manual arrangement efficiency (daily processing of 80,000 pieces requiring 6 workers), high misalignment rate (about 2.5%, with monthly rework costs exceeding 50,000 yuan), and rising labor costs (annual labor costs exceeding 900,000 yuan).

In 2024, the manufacturer introduced 3 sets of automatic spring tray arrangement equipment, achieving the following upgrades:

Efficiency Improvement: A single device processes 120,000 springs per day. 3 devices replace 6 workers, increasing the daily output from 80,000 pieces to 360,000 pieces, with an efficiency improvement of 350%.

Precision Optimization: The misalignment rate decreased from 2.5% to below 0.05%, reducing monthly rework costs by 48,000 yuan and annual cost savings by 576,000 yuan.

Cost Reduction: The annual depreciation + energy consumption cost of the equipment is about 200,000 yuan. Compared with the original annual labor cost of 900,000 yuan, the annual savings are 700,000 yuan, with an investment payback period of only 8 months.

In addition, after the equipment is connected to the enterprise’s MES system, it can real-time monitor the output of various specifications of springs, providing data support for order scheduling and further improving the accuracy of production plans.

Conclusion: Small Equipment Drives Great Value—Automated Arrangement Is a “Must-Answer Question” for Manufacturing Upgrading

Under the general trend of “cost reduction, efficiency improvement, and quality enhancement” in the manufacturing industry, the automatic spring tray arrangement equipment seems to be a “small device” in the production process, but it can close the “last mile” of spring production and solve the long-standing pain points of enterprises such as manual dependence, out-of-control precision, and high costs. For enterprises pursuing automated upgrading, selecting a suitable automatic spring tray arrangement equipment can not only quickly improve production capacity and precision but also lay the foundation for the subsequent construction of intelligent factories. After all, an efficient production closed loop starts with the precise arrangement of every spring.