In the intricate landscape of modern manufacturing, where precision and efficiency are paramount, the automatic spring white disc machine has emerged as a silent workhorse, redefining how small but critical components are assembled. This specialized automated system, designed to streamline the pairing of springs with white discs—common in industries ranging from automotive to electronics—combines mechanical precision, intelligent control, and adaptive technology to meet the demands of high-volume, high-accuracy production.

The Core Function: Marrying Precision with Speed

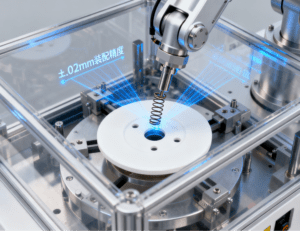

At its heart, the automatic spring white disc machine is engineered to perform a deceptively simple yet technically demanding task: aligning, inserting, and securing springs into white disc components with minimal human intervention. Springs, often delicate and prone to deformation, and white discs (typically made of plastic, metal, or composite materials) require consistent positioning to ensure functionality in end products—whether as part of a valve mechanism, a damping system, or an electronic switch.

Traditional manual assembly of these components is not only labor-intensive but also riddled with risks: uneven alignment can compromise product performance, while fatigue from repetitive work increases error rates. The automatic spring white disc machine eliminates these pitfalls by integrating several key features:

High-precision feeding systems: Vibratory bowls or conveyor belts with custom tooling separate and orient springs and white discs, ensuring each component arrives at the assembly station in the correct posture.

Robotic pick-and-place mechanisms: Equipped with vision sensors, these robotic arms identify, grasp, and position springs with micron-level accuracy, placing them into pre-drilled or molded slots on the white discs.

Adaptive pressing units: After insertion, the machine applies controlled pressure to secure the spring in place, adjusting force based on component size or material to avoid damage.

Real-time quality inspection: Cameras and sensors check for proper alignment, missing components, or defects, rejecting faulty assemblies instantly to maintain batch consistency.

Why It Matters: Transforming Industrial Efficiency

The impact of the automatic spring white disc machine extends far beyond mere automation—it addresses critical pain points in modern manufacturing:

Boosting production throughput: By operating 24/7 with minimal downtime, these machines can assemble hundreds to thousands of spring-white disc pairs per hour, far outpacing manual rates. This scalability is invaluable for industries with tight production deadlines, such as automotive part suppliers or consumer electronics manufacturers.

Ensuring uniform quality: Human variability is eliminated. Every assembly adheres to preprogrammed tolerances, reducing waste from defective parts and lowering the need for post-production rework. For safety-critical applications—like brake system components—this consistency is non-negotiable.

Reducing operational costs: While the initial investment in automated equipment is significant, long-term savings are substantial. Labor costs plummet, and lower scrap rates, combined with energy-efficient designs, create a compelling return on investment over time.

Enhancing worker safety: By handling small, potentially hazardous components (e.g., sharp metal springs or fragile discs), the machine minimizes worker exposure to repetitive strain injuries or accidental cuts, fostering a safer workplace.

Innovation in Action: Customization for Diverse Industries

What sets advanced automatic spring white disc machines apart is their adaptability. Modern systems are not one-size-fits-all; they are programmable to accommodate varying sizes of springs (from tiny coil springs to larger compression springs) and white discs (different diameters, slot configurations, or materials).

For example, in the electronics industry, where miniaturization is key, the machine can be calibrated to handle micro-springs and thin plastic discs used in smartphone buttons. In automotive manufacturing, it adjusts to sturdier metal springs and heat-resistant discs for engine valves. This flexibility is enabled by user-friendly HMI (Human-Machine Interface) panels, where operators can input new parameters or switch between production recipes in minutes.

The Future: Smart Integration in Industry 4.0

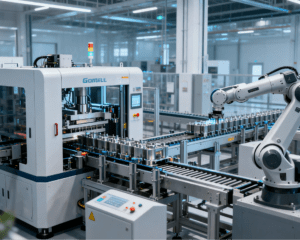

As manufacturing evolves toward Industry 4.0, automatic spring white disc machines are becoming smarter and more connected. Integration with IoT (Internet of Things) sensors allows real-time monitoring of performance metrics—such as cycle time, error rates, or energy usage—enabling predictive maintenance to prevent breakdowns. Machine learning algorithms can even analyze historical data to optimize feeding speeds or adjust pressure settings, further improving efficiency.

Moreover, these machines are increasingly part of automated production lines, communicating with upstream component suppliers and downstream packaging systems to create a seamless workflow. This interconnectedness reduces bottlenecks and ensures that the spring-white disc assemblies flow into final product assembly without delays.

Conclusion

The automatic spring white disc machine may operate behind the scenes, but its role in modern manufacturing is indispensable. By merging precision, speed, and adaptability, it not only elevates product quality but also empowers manufacturers to meet the ever-growing demands of global markets. As industries continue to pursue greater efficiency and reliability, this unsung hero of the assembly line will undoubtedly remain a cornerstone of smart, sustainable production.