With the cosmetic industry pursuing personalized and high-quality production, non-standard eyebrow pencil assembly machines are becoming the core driving force for upgrading production lines. Ruizhi Intelligent Manufacturing keeps abreast of industry demands, integrating cutting-edge technology and practical experience to lead the development direction of this field. Below are three key trends shaping the future of non-standard eyebrow pencil assembly machines.

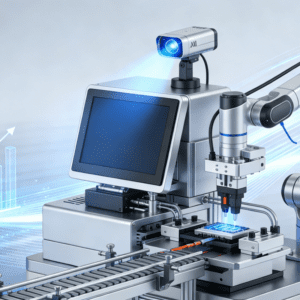

Intelligent Integration Upgrade, Reconstructing Production Precision

Intelligent control has become a core trend in non-standard equipment. Ruizhi integrates PLC systems, AI visual inspection and servo-driven positioning, realizing real-time monitoring and automatic adjustment of assembly parameters. The equipment can accurately identify deviations in lead insertion and cap fitting, with precision reaching ±0.02mm. It also uses big data analysis to optimize processes, reducing defect rates to below 1.5%. This intelligent upgrade not only replaces 6-8 manual workers but also ensures consistent product quality, adapting to the high-standard requirements of cosmetic factories.

Flexible Customization Deepening, Adapting to Diversified Demands

Market demand for eyebrow pencils (twist-up, retractable, double-headed) promotes flexible customization of non-standard equipment. Ruizhi’s solutions feature quick-change fixtures, enabling model switching in 3 minutes to match different sizes and structures of eyebrow pencil cases. The equipment can be customized with exclusive assembly processes for special processes like non-halogen rapid curing, solving the pain points of traditional equipment’s poor adaptability. This flexibility helps enterprises quickly respond to market changes and gain competitive edges.

Green Compliance Integration, Aligning with Beauty Industry Norms

Green and compliant production has become a rigid requirement. Ruizhi’s non-standard assembly machines adopt 316L stainless steel and food-grade parts, fully complying with GMP standards. Energy-saving motors and low-noise designs reduce energy consumption and environmental impact, in line with sustainable beauty trends. Meanwhile, the integrated leak testing and dust removal functions ensure the cleanliness of the production process, meeting the safety requirements of skincare and cosmetic products.

Ruizhi Intelligent Manufacturing adheres to technological innovation, integrating these trends into product R&D. Its non-standard eyebrow pencil assembly machines help enterprises overcome production bottlenecks, achieving efficient, precise and compliant production upgrades in the ever-changing cosmetic market.