Lotion pumps are essential packaging for daily chemical and cosmetic products, but many enterprises are trapped in the high cost of manual assembly. From labor wages to rework losses caused by low efficiency and high defects, manual assembly has become a heavy burden affecting profitability. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, offers efficient lotion pump assembly machines to replace manual operations, helping enterprises achieve substantial cost reduction and efficiency improvement.

The Hidden Costs of Manual Lotion Pump Assembly: Beyond Labor Wages

The high cost of manual assembly is not just about direct labor wages. Firstly, low efficiency leads to opportunity costs: A worker can only assemble 800-1000 lotion pumps per day, and production capacity is difficult to scale up, missing market supply deadlines. Secondly, high defect rates cause material waste: Manual operations are prone to errors such as loose fitting and leakage, with a defect rate often exceeding 3%, resulting in repeated rework and material loss. Thirdly, management costs increase: Enterprises need to invest a lot in training, supervision and labor dispatch, which further pushes up the overall assembly cost. These hidden costs make manual assembly increasingly uneconomical in large-scale production.

Ruizhi’s Automated Solution: Cutting Costs at the Root

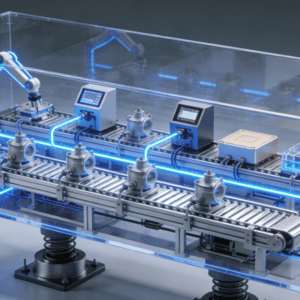

Targeting the cost pain points of manual assembly, Ruizhi’s efficient lotion pump assembly machine achieves root-level cost reduction through non-standard customization and full-process automation. Firstly, reducing labor dependence: The full-automatic process integrates feeding, assembly, airtightness testing and packaging, replacing 8-10 manual workers, and reducing labor costs by 65% directly. Secondly, improving efficiency and reducing opportunity costs: The daily output can reach 15,000 pieces, which is 15 times that of manual work, easily meeting large-scale production needs. Thirdly, reducing waste with high precision: Equipped with visual positioning and servo control systems, the defect rate is reduced to below 0.2%, minimizing material waste and rework costs.

Practical Results: From High Labor Costs to Stable Profit Growth

Ruizhi’s automated solution has been fully verified in practical applications. A medium-sized daily chemical enterprise once spent 200,000 yuan on labor costs for lotion pump assembly every month, with a defect rate of 3.5%. After adopting Ruizhi’s customized assembly line, the monthly labor cost was reduced to 70,000 yuan, and the defect rate dropped to 0.18%. The investment was recovered in 6 months. In addition, the 12-minute quick-change tooling system adapts to multi-spec production, avoiding the cost of additional equipment purchase. Ruizhi’s one-stop service from scheme design to after-sales maintenance also reduces equipment operation and maintenance costs.

In the fierce market competition, controlling assembly costs is the key to improving enterprise profitability. Ruizhi Intelligent Manufacturing’s lotion pump assembly machine, with its high efficiency, high precision and low operation cost, provides a reliable path for daily chemical enterprises to get rid of the high cost of manual assembly. Choosing Ruizhi’s automation solution means choosing a more economical and efficient production mode.