As one of the key processes in metal forming and manufacturing, die casting is widely used in the automotive, electronics, electrical machinery, home appliances, and mechanical equipment sectors. With its advantages of high forming precision, high production efficiency, and strong product consistency, die casting has gradually become a common manufacturing method for structural components of many industrial products. This article will systematically introduce die casting from aspects such as its definition, process composition, key equipment, and practical functions.

Die Casting is a processing method that uses high pressure to quickly inject molten metal into precision metal molds, and forms metal parts of specific shapes through cooling and solidification. Compared with traditional casting, die casting emphasizes high-pressure and high-speed filling more, and has significant advantages in product dimensional accuracy, surface quality, and production efficiency.

Currently, commonly used die casting materials include aluminum alloys, zinc alloys, magnesium alloys, etc. Among them, aluminum alloy die casting is the most widely used due to its light weight and excellent mechanical properties.

Key Components of Die Casting

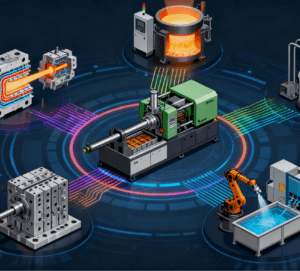

Die casting usually consists of the following core links and elements:

Die Casting Mold: The mold is the fundamental infrastructure of die casting, composed of moving mold, fixed mold, gating system, venting channels, cooling system, etc. The mold structure directly affects the product shape, dimensional accuracy, and production efficiency, so it has high requirements for quality and service life.

Die Casting Machine: The die casting machine is the main equipment for die casting forming. According to the feeding method of molten metal, it can be divided into cold-chamber die casting machines and hot-chamber die casting machines. (Cold-chamber machines are often used for high-melting-point metals such as aluminum alloys and magnesium alloys; hot-chamber machines are suitable for low-melting-point materials such as zinc alloys. The die casting machine injects molten metal into the mold cavity at high speed through the injection system, and completes the forming under high pressure and forced cooling.)

Metal Melting and Heat Preservation System: Metal raw materials need to be heated and melted in a melting furnace, and the temperature is maintained at an appropriate level through a holding furnace to ensure the fluidity of the molten metal and the stability of the forming process. The quality of melting is related to the internal structure, strength, and surface quality of the product.

Spraying and Demolding System: To ensure the smooth operation of the mold, the mold needs to be regularly sprayed with a release agent, which can not only protect the mold but also improve the demolding effect of the product.

Post-Processing Procedures: After the die castings are demolded, they usually need to undergo processes such as deburring, machining, polishing, and surface treatment to make the products meet the design requirements and application standards.

Functions and Advantages of Die Casting

Due to its process characteristics, die casting plays multiple roles in modern manufacturing:

Enabling High-Precision Forming of Complex Structures: Die casting molds can form complex geometric structures in one go, ensuring good dimensional consistency and high surface quality of products, and reducing subsequent processing workload.

Improving Production Efficiency, Suitable for Mass Manufacturing: Die casting is a high-speed forming process. Once the mold is finalized, the production cycle is short and the unit cost is low, making it suitable for large-scale mass production.

Enhancing Product Performance and Stability: Die castings have high density, good strength, and uniform internal structure, which can meet the reliability requirements of mechanical parts, automotive structural components, etc.

Supporting Lightweight Design: Light metal materials represented by aluminum alloys and magnesium alloys can be formed by die casting, which can effectively reduce product weight and is suitable for fields such as automotive lightweighting and electronics thinning.

Expanding Multi-Industry Applications: Die casting is widely used in automotive engine casings, electrical machinery housings, communication equipment structural components, lamp housings, home appliance accessories, etc., covering industrial and consumer sectors.

Application Trends of Die Casting

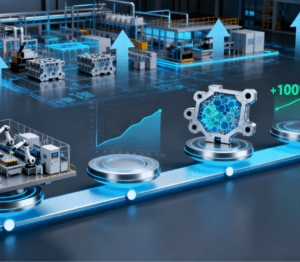

As the manufacturing industry moves towards automation, intelligence, and green development, die casting is also showing new technological trends:

Automated Die Casting Production Lines: Integrating technologies such as robotic part picking, automatic spraying, and visual inspection to improve consistency and efficiency.

Application of Lightweight Materials: The demand for aluminum-magnesium alloy die casting continues to grow, and the lightweighting of structural components has become a key focus in design.

Precision Die Casting and Thin-Wall Forming Technology: Meeting the demand for high-precision parts in new energy vehicles, 5G communication equipment, and other fields.

Green Production: Reducing energy consumption, optimizing melting processes, and improving material utilization to achieve a more environmentally friendly manufacturing process.