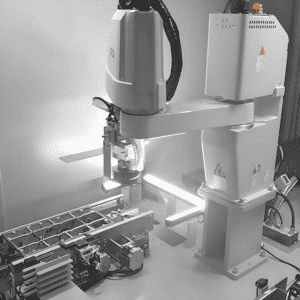

In the era of intelligent manufacturing, efficient and precise material handling is the key to improving production efficiency and reducing costs for enterprises. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing focuses on the R&D and production of automated handling equipment, and its 4-Axis Robotic Frame Pick-up System has become a core product favored by industries such as automotive parts, 3C electronics, and injection molding, integrating precision, efficiency, and flexibility to help customers achieve lean production.

The Core Advantage of Stable Material Handling

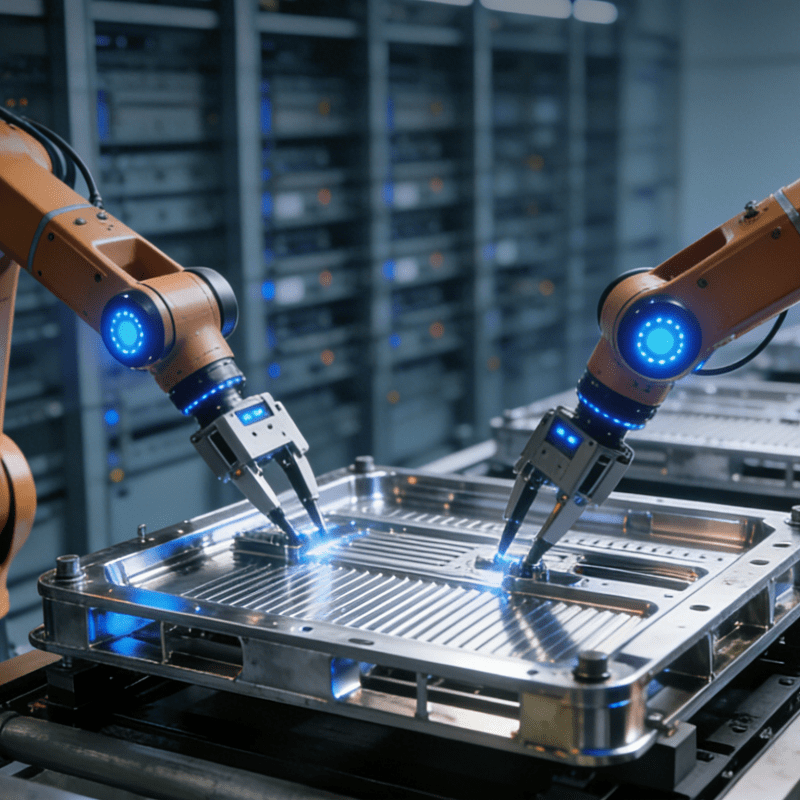

The 4-Axis Robotic Frame Pick-up System developed by Ruizhi Intelligent Manufacturing adopts advanced servo control technology and high-precision positioning algorithms, with a repeat positioning accuracy of ±0.02mm, which can accurately complete the picking, moving, and placing of frames and other workpieces. Compared with traditional manual handling or semi-automatic equipment, it effectively avoids errors caused by human operation, reduces workpiece damage, and ensures the stability of the production line. Whether it is light and small precision frames or heavy-duty workpieces, the system can operate stably, meeting the high-precision handling needs of various non-standard scenarios.

Breaking Through the Bottleneck of Production Efficiency

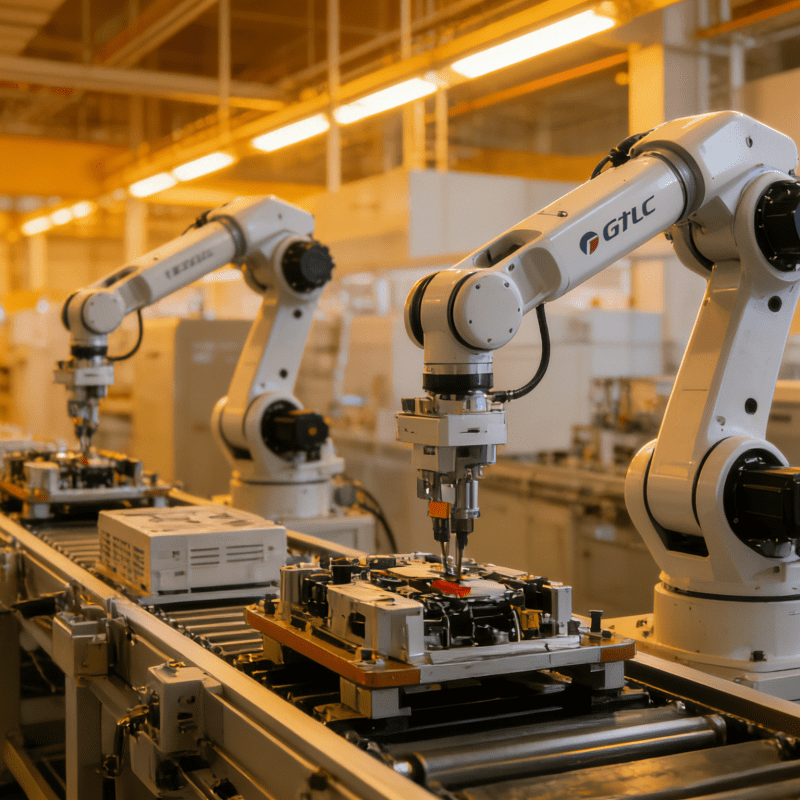

Efficiency improvement is the core demand of every manufacturing enterprise. Ruizhi’s 4-Axis Robotic Frame Pick-up System realizes 24-hour uninterrupted operation, with a handling speed 3-5 times that of manual work, greatly shortening the production cycle. The system can be seamlessly integrated with automated assembly lines, injection molding machines, and other equipment, realizing automatic connection of upstream and downstream processes, reducing manual intervention, and solving the pain points of low efficiency and high labor costs in traditional handling. It is estimated that the system can help customers reduce labor costs by 30% and improve overall production efficiency by more than 40%.

Adapting to Diverse Non-Standard Needs

As a non-standard automation expert, Ruizhi Intelligent Manufacturing fully considers the diverse needs of different industries and customers. The 4-Axis Robotic Frame Pick-up System supports customized design according to workpiece size, weight, handling distance, and on-site production layout. We provide tailored solutions, including customized end effectors, adjustable handling paths, and intelligent control systems, to ensure that the equipment can perfectly adapt to the actual production needs of customers. In addition, the system is equipped with a simple human-machine interface, which is easy to operate and maintain, reducing the professional requirements for operators.

Ruizhi Intelligent Manufacturing is committed to empowering the manufacturing industry with high-quality automation equipment. Our 4-Axis Robotic Frame Pick-up System takes precision as the foundation and efficiency as the goal, solving the handling pain points of enterprises and helping customers achieve intelligent upgrading. Choose Ruizhi, and choose a reliable partner for your efficient production.