In an era where manufacturing is rapidly shifting toward small-batch, customized production and “batch size one” demands, the limitations of traditional part-feeding solutions are becoming increasingly pronounced. For decades, vibratory bowl feeders have been the workhorses of assembly and packaging lines, reliably sorting small parts into consistent orientations for automated or manual handling. Yet as market needs evolve, a new technology—flexible feeding systems, which integrate robotics, vision, and precision motion control—is emerging as a transformative alternative, redefining efficiency and adaptability in part handling.

Vibratory bowl feeders earned their long-standing popularity for their ability to repeatedly align small parts in a specific direction, a critical function in high-volume production. However, their design is inherently rigid: each bowl is engineered for a single part type. This means switching to a new part requires swapping out the entire bowl, a process that devours valuable production time. In today’s landscape, where manufacturers must pivot quickly between product variants, such lengthy changeovers have become a major bottleneck.

Beyond inflexibility, noise is another persistent issue. “Vibratory bowls operate through constant vibration, creating significant noise pollution in factories,” notes Rick Tomaszewski, strategic account manager for Omron Automation America. This, combined with their limited adaptability, has spurred manufacturers to seek more versatile feeding solutions.

Armo-Tool’s Flexible Feeding Breakthrough

To address these challenges, Armo Tool—a provider of industrial tooling and automation based in London, Ontario—teamed up with Omron Automation and local distributor Taylor Fluid Systems to develop a flexible feeding system for a Tier 1 automotive supplier. The supplier, which produces brake lines for multiple passenger vehicle models, was struggling with vibratory bowls used to sort end-form fittings: frequent part changes led to excessive downtime, and inefficiencies hovered at 70% or lower.

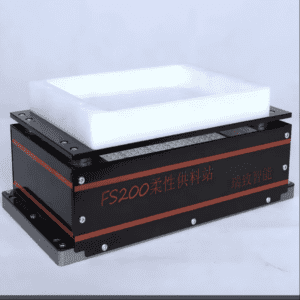

Leveraging Omron’s AnyFeeder flexible feeding system, paired with rotary and linear servos, FH vision technology, e-Cobra SCARA robots, and a Sysmac controller, the team created a integrated solution that delivered 99% efficiency from startup—nearly a 30% jump. Equally critical, changeover time plummeted to less than 10 minutes, a game-changer for rapid product switches.

“The AnyFeeder, when combined with vision-guided robots, outperforms traditional hand-tooled bowls by handling diverse parts—varying in size, shape, and material—with minimal retooling,” Tomaszewski explains. This flexibility slashes tooling costs and accelerates line transitions, key for meeting custom production demands.

Precision Through Vision Integration

A cornerstone of the system’s success is Omron’s FH vision technology, which guides the e-Cobra 600 SCARA robots in precise pick-and-place actions. The vision system verifies part accuracy, pinpoints coordinates of randomly oriented parts on the feeder bed, and ensures correct placement—critical for the automotive supplier, where attaching the wrong brake line fitting could trigger costly recalls.

The integration of poka-yoke (mistake-proofing mechanisms) further guarantees error-free operation, ensuring the right fitting is always matched to the right pipe. “This level of precision is non-negotiable in safety-critical applications like automotive braking systems,” Tomaszewski emphasizes.

Adaptability for the Future

Beyond immediate efficiency gains, the system’s adaptability shines in long-term use. “Customers can easily program new parts—even those with entirely different geometries—into the AnyFeeder at any time,” says Christina Koroll, account manager at Armo Tool. “Plus, at the end of a line’s lifecycle, the system can be repurposed for new projects, maximizing ROI.”

As manufacturing continues to prioritize agility, flexibility, and precision, flexible feeding systems are no longer just an alternative to vibratory bowls—they are becoming the backbone of next-generation production. By merging robotics, vision, and smart motion control, these systems not only solve today’s challenges of changeover time and noise but also lay the groundwork for adaptive, future-ready factories. In this shift, the rise of flexible feeding technology marks a pivotal step toward truly intelligent manufacturing.

Advantages of flexible automated hardware component feeding and assembly

Working process of flexible automated hardware component feeding and assembly equipment