Non-standard Automation Equipment: Five Core Advantages Leading the Path of Flexible Upgrading in the Manufacturing Industry

In the surging tide of Industry 4.0 and intelligent manufacturing, the traditional assembly line production mode is faced with many thorny problems such as multi-variety, small-batch production and a sharply shortened delivery cycle. When standardized equipment fails to meet the increasingly diverse personalized needs of enterprises, non-standard automation equipment, with its unique flexibility and customization features, has quietly transformed into a core “invisible engine” that helps enterprises reduce costs and improve production efficiency. This article will closely focus on practical application scenarios and deeply explore how non-standard equipment creates unique competitive advantages for the manufacturing industry.

Customized Production: Precisely Meeting the Personalized Needs of Enterprises

The core charm of non-standard automation equipment lies in “exclusive customization”. Completely different from standardized equipment, it can carry out modular design according to the special properties of products, the technological process, and even the actual space conditions of the workshop. Take a medical device manufacturing enterprise as an example. When conducting the aseptic assembly of precision parts, traditional equipment severely restricted production due to the pollution hazards brought about by human intervention that were difficult to avoid. However, after introducing a non-standard system with a non-isolation cabin and robotic arms working in coordination, a fully enclosed production environment was successfully established, and the product qualification rate increased significantly from the original 82% to 98%. This development mode that is completely driven by the needs of enterprises has enabled enterprises to completely get rid of the dilemma in the past where they were forced to adjust their own production needs to accommodate the equipment.

Flexible Upgrading: Responsively Adapting to the Changeable Market Demands

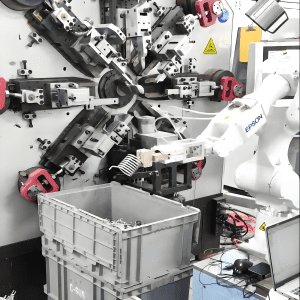

Against the backdrop of the increasingly fragmented consumer demands, the production line must possess extremely strong flexibility like a “Transformer”. Through the ingenious integration of the Programmable Logic Controller (PLC) and the visual recognition system, non-standard equipment has achieved the excellent function of “one machine with multiple uses”. For instance, a certain home appliance enterprise was once troubled by the frequent changes in the product specifications of overseas orders for a long time. Its customized non-standard assembly production line, by using the rapid model-changing technology, has reduced the adjustment time of the production line from the original 4 hours to only 20 minutes. Relevant data shows that for enterprises adopting flexible non-standard solutions, the average time for new products to be launched on the market can be shortened by 30% – 45%.

Dual Improvement of Efficiency and Precision: Breaking through the Limitations of Traditional Equipment

Standardized equipment often struggles to balance between production efficiency and processing precision. In contrast, non-standard equipment can successfully break this deadlock through targeted optimization. Take the automotive parts manufacturing industry as an example. When a certain enterprise was processing special-shaped gears, the processing errors of traditional machine tools led to a scrap rate of as high as 15% of the products. Through the specially designed multi-axis linkage special machine tool, combined with the online detection closed-loop system, not only has the daily production capacity increased sharply from 800 pieces to 2,400 pieces, but also the precision error has been accurately controlled within ±0.002mm. This characteristic of designing equipment specifically for specific products is especially suitable for the production and manufacturing of products with high complexity and high added value.

Optimization of the Total Life Cycle Cost: Cost Advantages from a Long-term Perspective

Although the initial investment in non-standard equipment is usually higher than that in standard equipment, when considering the entire service life cycle of the equipment, its Life Cycle Cost (LCC) is more advantageous. The case of a certain food packaging enterprise is highly representative: The enterprise originally used 3 standard filling machines and needed to be equipped with 6 operators. After the customized fully automatic filling-sealing-palletizing integrated machine was put into use, the number of equipment was reduced by 2 units, and it also achieved completely unmanned operation. Calculated based on a five-year service cycle, the labor cost savings exceeded 2 million yuan, and the floor area occupied by the equipment was reduced by 40%. More importantly, the preventive maintenance system equipped with the equipment has reduced the failure shutdown rate by 76%.

The Cradle of Technological Integration: An Ideal Testing Ground for Cutting-edge Technologies

Non-standard automation equipment can be regarded as an excellent application carrier for cutting-edge technologies such as the Industrial Internet of Things (IIoT), AI algorithms, and digital twins. For example, in the sanitary ware category, there are sanitary ware automatic assembly machines, bathroom fixture assembly equipment, toilet assembly lines, etc. In the automotive category, there are Contactor Assembly Machines, Fuse Assembly Machines, etc.a certain electronics foundry implanted a deep learning model into the non-standard detection equipment, increasing the defect recognition accuracy rate from 89% to 99.7% rapidly; a chemical enterprise used the AR remote operation and maintenance system to triple the equipment debugging efficiency. These innovative measures not only effectively solve the actual problems currently faced by enterprises, but also accumulate key core technical assets for enterprises in the process of digital upgrading.

With the in-depth implementation of the “14th Five-Year Plan for the Development of Intelligent Manufacturing”, the demand for non-standard automation equipment in the manufacturing industry is continuously increasing at an average annual rate of 18%. From 3C electronics to new energy, from medical devices to aerospace, non-standard equipment is reconstructing the production logic in an all-round way – it is no longer just a simple replacement of manual labor by machines. Instead, by deeply conforming to the unique needs of enterprises, it helps the manufacturing industry successfully create a stable competitive advantage in a market environment full of uncertainties.

As the “14th Five-Year Plan for the Development of Intelligent Manufacturing” is implemented with full force, the manufacturing industry’s appetite for non-standard automation equipment is growing voraciously at an average annual rate of 18%. Spanning across industries from 3C electronics to new energy, from medical devices to aerospace, non-standard equipment is engaged in a comprehensive overhaul of production logics. It represents a paradigm shift far beyond the simple substitution of manual labor with machines. By closely aligning with the idiosyncratic needs of each enterprise, it serves as the cornerstone upon which the manufacturing industry can erect a steadfast competitive stronghold in a market rife with uncertainties. The future of manufacturing is being rewritten, and non-standard automation equipment is the indelible pen driving this transformative narrative.