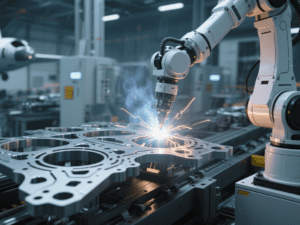

Against the backdrop of increasingly fierce global competition in the manufacturing industry, flexible manufacturing, as an emerging production model, is gradually becoming an important way for enterprises to improve efficiency and reduce costs. However, the realization of flexible manufacturing faces many challenges, such as complex production processes, high flexibility requirements, severe mixed production, and rising labor costs. With the continuous development of industrial technology, robots and automated equipment are playing an increasingly important role in the field of flexible manufacturing. Automated mechanisms based on technologies such as robots and modules are becoming key technologies to realize unmanned and intelligent production.

- Advantages of Robots and Automated Equipment in Flexible Manufacturing

Automated mechanisms such as robots and modules play an irreplaceable role in flexible manufacturing. They can undertake repetitive and tedious work, realize automated production processing, thereby greatly reducing labor costs and improving production efficiency. In addition, automation technology can effectively reduce human errors, improve product quality, and realize traceability and controllability of the production process.

Freeing Human Resources to Achieve Higher Output and Faster Production Speed

In the manufacturing industry, many jobs require workers to perform repetitive labor, which is labor-intensive and inefficient. By introducing automated mechanisms such as robots and modules, these tasks can be replaced by machines, reducing the labor intensity of workers and ensuring the stable operation of the production line. At the same time, automated equipment can work in harsh environments such as high temperature, low temperature, and high risk, which greatly reduces the restrictions on the human working environment and avoids potential injury risks.

High Flexibility and Programmability

Robots and automated equipment have high flexibility and programmability. They can not only repeatedly perform a single task but also be modified and adjusted according to different product requirements. This flexibility makes the layout and process of the production line more flexible, enabling rapid adaptation to changes in market demand. In addition, modular production can reduce equipment investment and maintenance costs, shorten product development cycles, and improve market competitiveness.

High Precision and High Stability for Producing High-Quality Products

Compared with manual operations, robots can ensure the consistency of operation results and avoid errors caused by human factors. This is particularly important for industries with high product quality requirements, such as home appliances, furniture, automobiles, and electronic equipment manufacturing. By introducing automated equipment, enterprises can ensure the consistency and reliability of product quality and improve customer satisfaction.

- Applications of Robots and Automated Equipment in Flexible Manufacturing

Haiyan Technology has been deeply engaged in intelligent vision solutions in the field of flexible manufacturing. Based on automated mechanisms such as robots and modules, we provide unmanned and intelligent solutions for production lines. By introducing advanced robot technology and module technology and deeply integrating them with self-developed machine vision technology, we help enterprises realize unmanned production sites, standardized and intelligent production processes. In practical applications, our solutions cover intelligent pasting, intelligent locking, intelligent assembly, and intelligent leak detection.

Intelligent Pasting

Haiyan Technology’s self-developed pasting equipment is equipped with a visual positioning and verification system, which can realize high-precision and high-quality online printing and pasting of printed materials. The equipment can perform full-process automated operations such as automatic grabbing, peeling, positioning, pasting, and information verification, greatly improving production efficiency and pasting quality. At the same time, we adopt a modular design, enabling the equipment to adapt to the needs of different mixed production conditions. In practical applications, it can be widely used in scenarios such as energy efficiency label pasting, nameplate pasting, logo pasting, and label pasting.

Intelligent Locking

Haiyan Technology combines visual guidance, visual positioning, visual inspection with robot technology to achieve high-precision locking. The 3D camera is used to obtain the accurate position and angle information of the equipment, which is compared with the preset screw position and angle. Machines replace manual operations, effectively ensuring locking precision and quality. This solution can be widely applied to any screw locking scenarios such as vertical locking and horizontal locking.

Intelligent Assembly

Haiyan Technology adopts a collaborative working mode of robot technology and 2D and 3D visual positioning technology to realize the grabbing of different targets. This solution is suitable for mixed production conditions, effectively replacing manual operations and reducing labor intensity. At the same time, we also support combination with locking equipment to realize intelligent interconnection of handling and locking fixing processes.

Intelligent Leak Detection

Haiyan Technology integrates a flexible visual adaptive mechanism, which can accurately locate leak points in complex backgrounds. Through advanced artificial intelligence technology and image processing algorithms, we can quickly and accurately detect leak points, thereby ensuring the quality of target products. This solution can be widely applied to multiple fields such as air tightness testing, water resistance testing, and sealing testing.

With the continuous development of industrial technology, the application of robots and automated equipment in the field of flexible manufacturing will become more extensive. Haiyan Technology has been committed to researching and developing innovative technologies, promoting the development of intelligent manufacturing, and helping enterprises improve production efficiency and product quality by continuously optimizing the performance and functions of automated equipment. At the same time, Haiyan Technology has always attached importance to cooperation and communication with manufacturing enterprises, deeply understanding their needs and pain points, so as to better provide them with more advanced and efficient intelligent equipment and solutions. In the future, Haiyan Technology will continue to give full play to its technical advantages, contribute to the sustainable development of the intelligent manufacturing industry, and help “Made in China” go global.