In modern manufacturing, precision gears, as key components, are widely used in numerous fields such as automotive, aerospace, and industrial machinery. From power transmission in automotive engines to precise motion control in medical equipment, the performance of precision gears directly affects the operational accuracy and stability of entire systems. During the machining process of precision gears, the control of tooth profile errors has always been a focus of the industry.

Tooth profile error refers to the deviation between the actual tooth profile and the theoretical tooth profile during gear machining. Such errors can cause noise and vibration when gears are in operation, reduce transmission efficiency, and even affect the service life of equipment. In traditional precision machining, tooth profile errors arise from multiple factors, including tool wear, reduced machine tool accuracy, and unreasonable setting of machining process parameters.

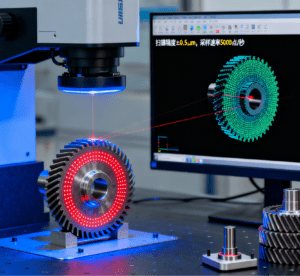

Non-Contact Optical Measurement: A Leap Forward in Detection Efficiency

For a long time, the detection of tooth profile errors has mainly relied on contact measurement methods, such as the use of gear measuring centers. Although this method offers high accuracy, the measurement process is cumbersome, requires professional operators, and has a slow measurement speed, making it difficult to meet the needs of large-scale production. With the development of science and technology, non-contact detection technologies have gradually emerged, among which optical measurement technology has made a name for itself in the field of CNC precision machining. Through means such as laser scanning and image recognition, 3D data of gear tooth profiles can be quickly acquired, enabling efficient detection of tooth profile errors. In the CNC machining industry in Dongguan, some advanced enterprises have introduced such optical detection equipment, which has significantly improved detection efficiency while achieving accuracy comparable to that of traditional contact measurement.

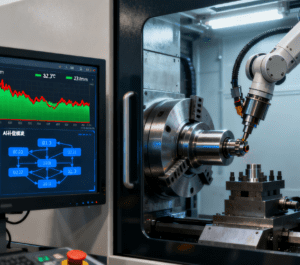

Intelligent & Multi-Axis Linkage: Innovations in Error Compensation Technology

In terms of tooth profile error compensation technology, new breakthroughs are constantly emerging. In the past, compensation mainly relied on manual experience to adjust machining parameters; this method was not only inefficient but also had limited compensation effects. Today, compensation technology based on big data and artificial intelligence has become a development trend. During CNC machining, by real-time collecting the operating data of machine tools, tool status, and various parameters during the gear machining process, machine learning algorithms are used to establish mathematical models. These models can accurately analyze the causes of tooth profile errors, automatically generate optimal compensation schemes, adjust machining parameters, and achieve precise compensation for tooth profile errors. For example, in the manufacturing of precision gears involved in mold machining, after adopting this intelligent compensation technology, tooth profile errors have been significantly reduced, and the transmission accuracy and stability of gears have been greatly improved.

In addition, in the field of multi-axis CNC machining (such as 5-axis CNC machining and 4-axis CNC machining), compensation for tooth profile errors can also be achieved by optimizing tool path planning. Using advanced CAM software, more reasonable tool movement trajectories are generated based on the design parameters of gears and actual machining conditions, reducing tooth profile errors caused by improper tool movement. This error compensation technology based on multi-axis linkage provides a more effective solution for the machining of precision gears with complex tooth profiles.

Industrial Empowerment: The Far-Reaching Impact of Technological Breakthroughs

Complementing these detection and compensation innovations, automatic injection-molded part feeding and assembly systems have been widely applied in the mass production of precision gears. These systems realize high-precision, continuous feeding and assembly of injection-molded auxiliary components (such as wear-resistant bushings, protective housings, and positioning sleeves) that match precision gears, ensuring the dimensional consistency of auxiliary parts and their tight fit with gear bodies. Working in tandem with advanced detection and intelligent compensation technologies, they further eliminate assembly-related deviations, enhance the overall operational reliability of gear systems, and lay a solid foundation for the large-scale application of precision gears in high-end equipment.

The new breakthroughs in tooth profile error detection and compensation technology for precision gear machining have brought higher machining accuracy and production efficiency to the manufacturing industry. From advanced detection methods to intelligent compensation technologies, these innovations are driving the precision gear machining industry to new heights and contributing to the improvement and optimization of equipment performance in various fields.