Debut of New Products: The “Wolf Series” Makes a Stunning Appearance

On October 28, 2025, the Asia International Logistics Technology and Transportation Systems Exhibition (CeMAT ASIA) grandly opened in Shanghai. As an annual flagship event in the logistics technology sector, this exhibition attracted over 900 high-quality exhibitors from fields such as logistics robots and industrial-level autonomous driving, jointly showcasing cutting-edge industry technologies and innovative achievements.

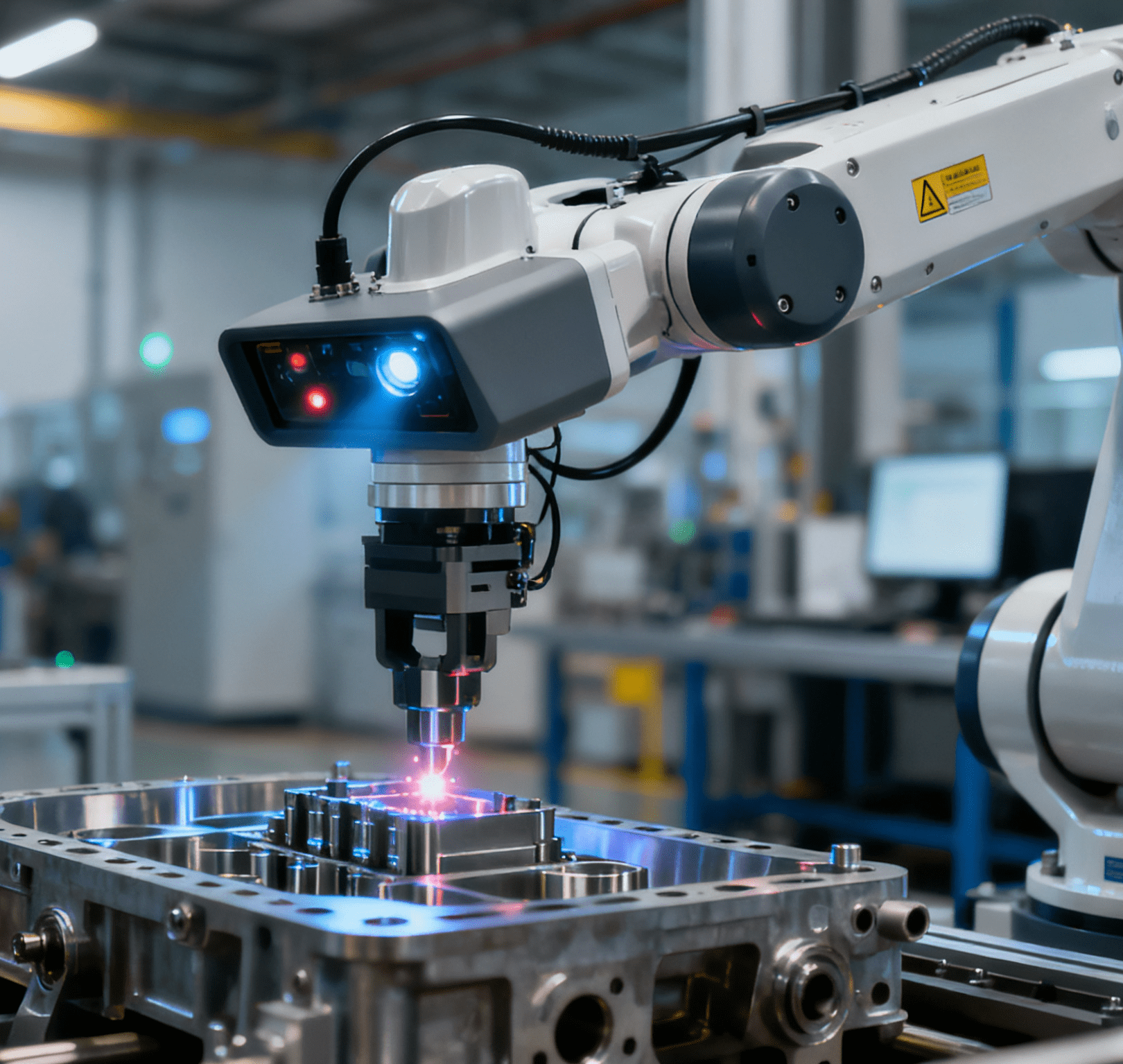

On the eve of the 11.11 Grand Promotion, JD Logistics launched three new members of the “Wolf Series” for the first time at this exhibition – the Smart Wolf Extended Version, Sky Wolf Four-Way Shuttle, and Automated Sorting Wall (End-to-End Version) – officially expanding its powerful robot fleet. These three robots are mature technical solutions meticulously developed by JD Logistics for grand promotion scenarios, based on years of practical experience and technical accumulation. Complementing this new lineup is the upgraded robotray rack loader, a key equipment optimized for pallet and rack handling that further enriches the “Wolf Pack” ecosystem. Together, they fully demonstrate the strong capability of artificial intelligence in reshaping new models of warehouse intelligence.

Intelligent Collaboration: Empowering Logistics Upgrading Across the Entire Chain

This year’s 11.11 Grand Promotion marked the first practical test of the large-scale deployment of JD Logistics’ robot fleet, truly realizing “AI + Robot” -driven operation across the entire logistics chain. Currently, these robots have been widely applied in more than 500 warehouses around the world, serving as a strong support for the efficient operation of JD Logistics.

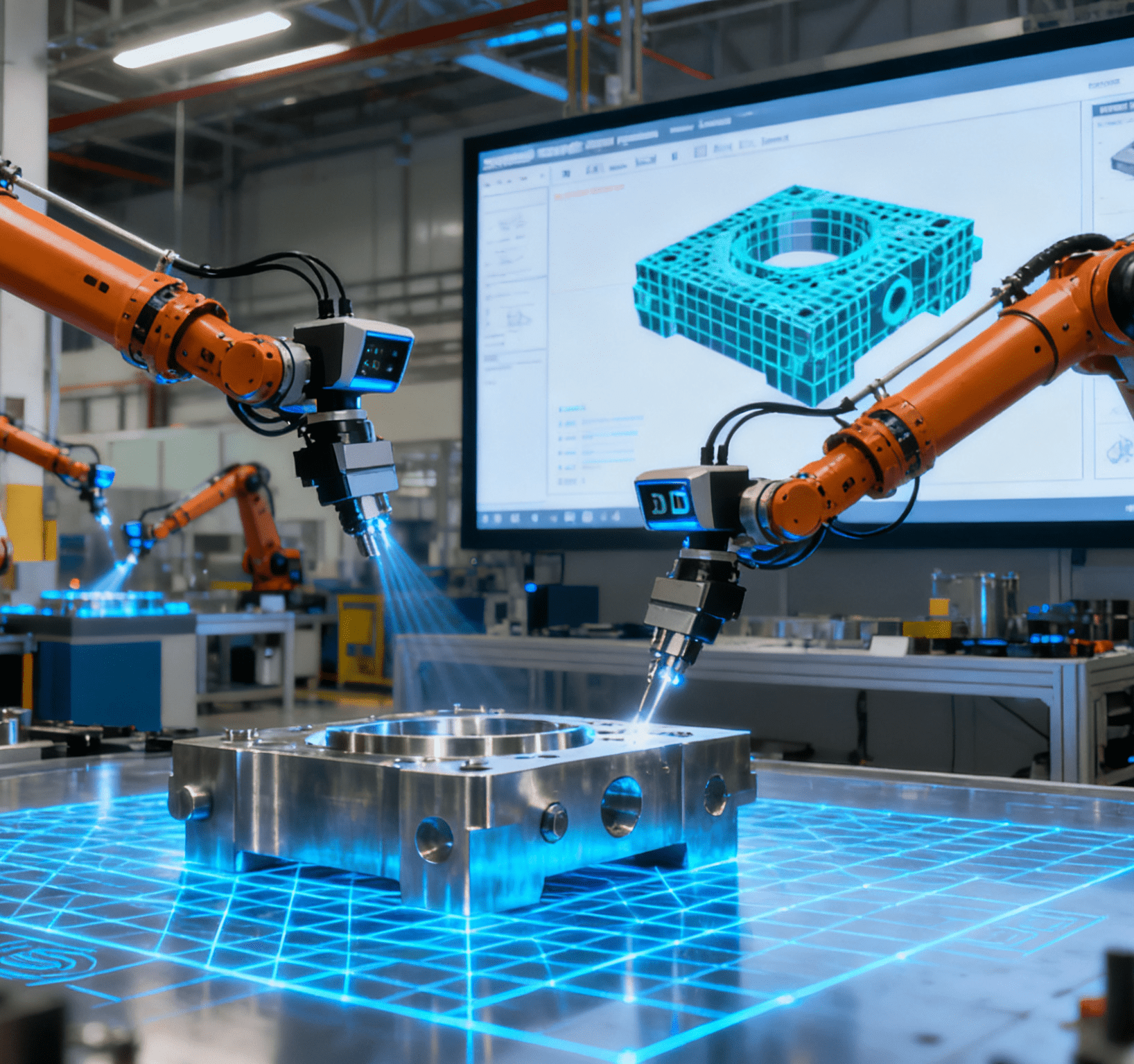

Under the intelligent dispatching of JD Logistics’ Super Brain AI Large Model, the “Wolf Series” robots no longer operate independently; instead, they achieve interconnection and intelligent collaboration. In the warehousing link:

– The Sky Wolf Four-Way Shuttle, equipped with laser radar, supports four-dimensional movement (forward, backward, left, and right), enabling efficient cargo transfer without switching lanes and realizing high-density storage.

– The Smart Wolf Series focuses on “goods-to-person” picking, accurately and quickly completing cargo handling and picking tasks.

– The robotray rack loader undertakes the critical task of loading and unloading palletized goods to and from high-rise racks. With its adaptive clamping mechanism and precise positioning system, it can handle various sizes of pallets and cooperate with the Sky Wolf Four-Way Shuttle to realize seamless connection between goods inbound and rack storage, reducing the time cost of intermediate links by 25%.

In the sorting link, the Automated Sorting Wall (End-to-End Version) adopts a three-dimensional layered design, with a sorting efficiency of up to 15,200 items per hour. It efficiently handles massive orders, covering scenarios such as order sorting, return classification, and small-item consolidation. Compared with traditional sorting equipment, its area efficiency is increased by 200%, greatly improving sorting efficiency and accuracy.

Meanwhile, the Smart Wolf Shuttle plays a key role in ultra-high automated warehouses. By closely cooperating with elevators, it significantly improves space utilization and inbound/outbound efficiency, meeting the needs of large-scale warehouse centers. The robotray rack loader also synergizes with the Smart Wolf Shuttle in ultra-high warehouses, undertaking the transfer of goods between the ground operation area and the shuttle’s lifting platform, forming a smooth vertical transportation channel.

This closed-loop collaborative model across the entire process – from cargo warehousing and storage, to order picking, and then to sorting and distribution – connects each link closely, forming an efficient and intelligent logistics operation system. During the practical operation of the 11.11 Grand Promotion, the “Wolf Series” robot fleet fully demonstrated its strong collaborative operation capabilities. Whether it was meeting the demand for efficient storage and picking of multi-category goods in popular product warehouses, dynamically adapting to large fluctuations in orders during the sorting link, or planning cargo location layouts in advance to cope with inventory pressure, it performed with ease, strongly ensuring the stable and efficient operation of logistics during the grand promotion. Specifically, the robotray rack loader showed outstanding performance in handling peak inbound volumes, completing 30% more pallet handling tasks per hour than traditional equipment and effectively alleviating the pressure of goods accumulation.

Future Blueprint: Sustained Innovation Leading Transformation

Looking ahead, a person in charge of JD Logistics Technology stated with confidence that the company will unswervingly continue to optimize the collaboration between the large model and the “Wolf Series” robots. By continuously tapping into the potential of the large model, it will further enhance the robots’ independent decision-making capabilities and task execution efficiency in complex warehouse environments, enabling them to respond more flexibly and intelligently to various unexpected situations and diverse business needs. For the robotray rack loader, the focus will be on integrating AI visual recognition to realize automatic identification of damaged pallets and intelligent adjustment of clamping force, further improving operation safety and adaptability.

At the same time, JD Logistics will commit to enhancing the environmental adaptability and business scalability of intelligent warehouses. Aiming at the personalized needs of customers in different industries and of different scales, it will develop customized intelligent warehouse solutions that are more in line with actual scenarios, promoting the in-depth application and popularization of intelligent warehouse technology in a wider range of fields. This includes tailoring the robotray rack loader for cold-chain warehouses and hazardous goods warehouses, developing low-temperature-resistant and explosion-proof versions to expand its application boundaries.

As a firm practitioner of “AI reshaping new warehouse models”, JD Logistics is well aware of its industry responsibilities and missions. In the future, the company will actively leverage its advantages in technological innovation and practical application, carry out extensive and in-depth cooperation with upstream and downstream enterprises in the industry, scientific research institutions, etc., share technological achievements and practical experience, and jointly promote the intelligent upgrading process of the entire logistics industry.

Under the guidance of the national strategy of “building an intelligent supply chain, improving the level of warehouse intelligence, and reducing social logistics costs”, JD Logistics will continue to increase investment in technology research and development, talent cultivation, and infrastructure construction, and constantly improve the intelligent supply chain ecosystem. Through efficient and intelligent logistics services, it will provide solid support for the development of the real economy, assist in industrial upgrading and high-quality economic development, and take more solid steps on the path of serving national strategies and promoting social progress.

Robots realize the automated assembly of automotive connectors