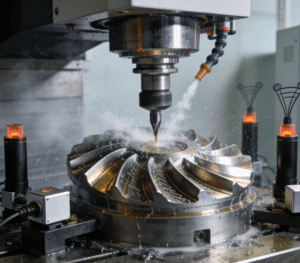

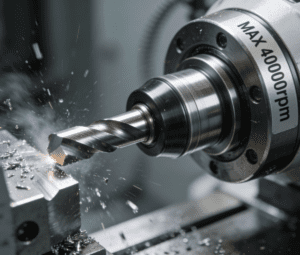

High-speed milling technology represents an innovation in modern manufacturing. It enables high-efficiency machining through the intelligent control strategies of intelligent machining systems. This article focuses on how intelligent systems optimize parameters such as spindle speed and cutting depth to enhance the precision and efficiency of precision machining under the conditions of higher rotational speed and micron-level cutting depth. The core content includes the optimal design of cutting tools, such as material selection and geometric adjustment, as well as process monitoring technologies to ensure machining stability and quality control. The article will analyze these elements step by step, laying a foundation for the subsequent discussion on intelligent control mechanisms.

Core of Intelligent Machining Control

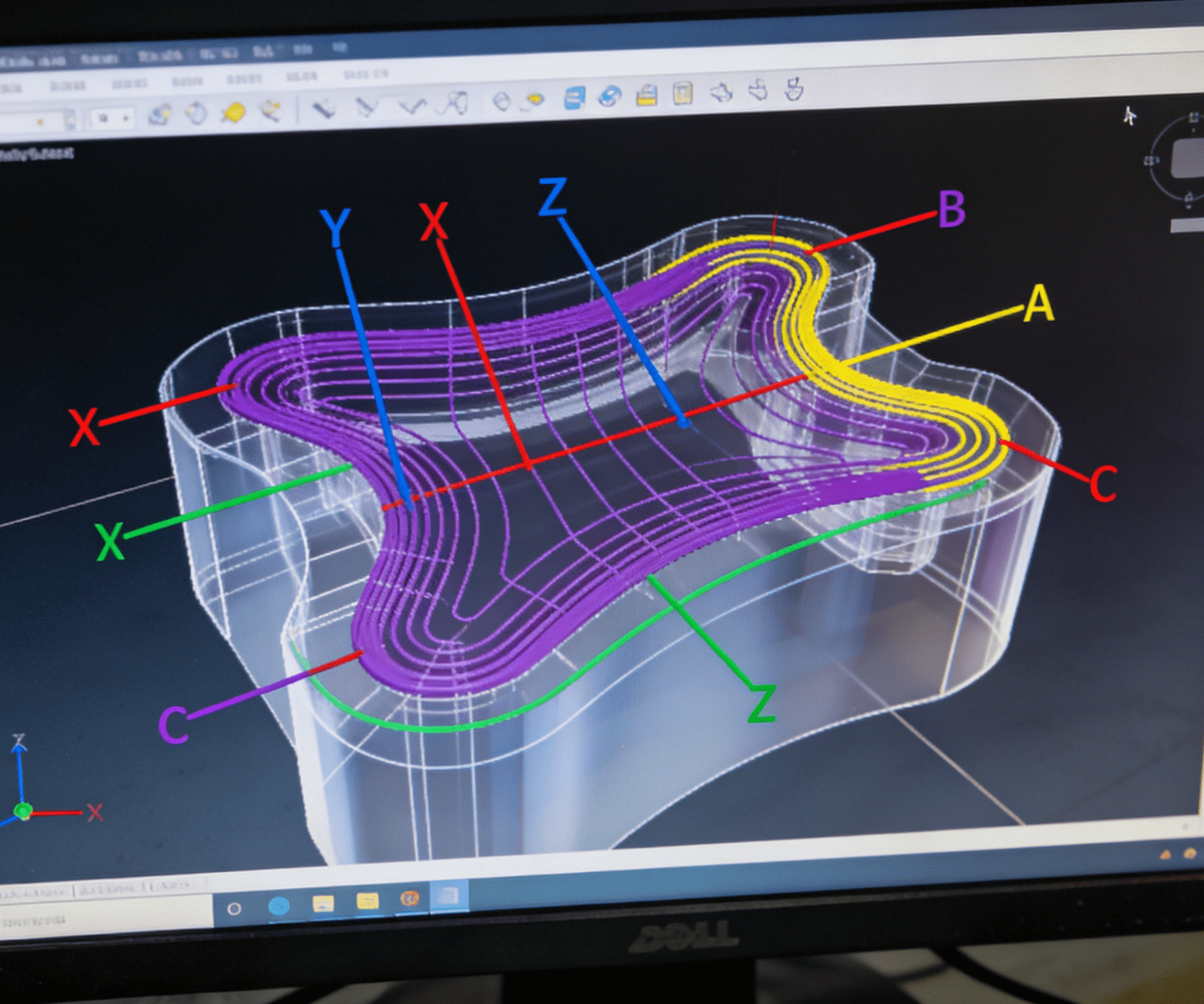

The key to achieving the high spindle speed and micro cutting depth pursued by high-speed milling lies in the intelligent control capability of the intelligent machining system. Modern intelligent systems can perform extremely precise dynamic adjustment of spindle speed and cutting depth through advanced algorithms. This relies on a powerful real-time feedback mechanism built into the system, which continuously monitors key parameters during the machining process, such as cutting force, vibration, and temperature changes. Based on this real-time data, the system applies complex control strategies (such as adaptive control and predictive control) to make decisions and adjustments within microseconds. For example, when a potential vibration trend is detected, the system can instantly fine-tune the rotational speed or feed rate to suppress it; when dealing with different material properties or tool conditions, the system can also automatically optimize the combination of cutting parameters. This intelligent real-time response and precise regulation are the fundamental guarantees for maintaining machining accuracy and surface quality even under the conditions of extremely high rotational speed and micron-level cutting depth.

Precise Adjustment of Rotational Speed and Cutting Depth

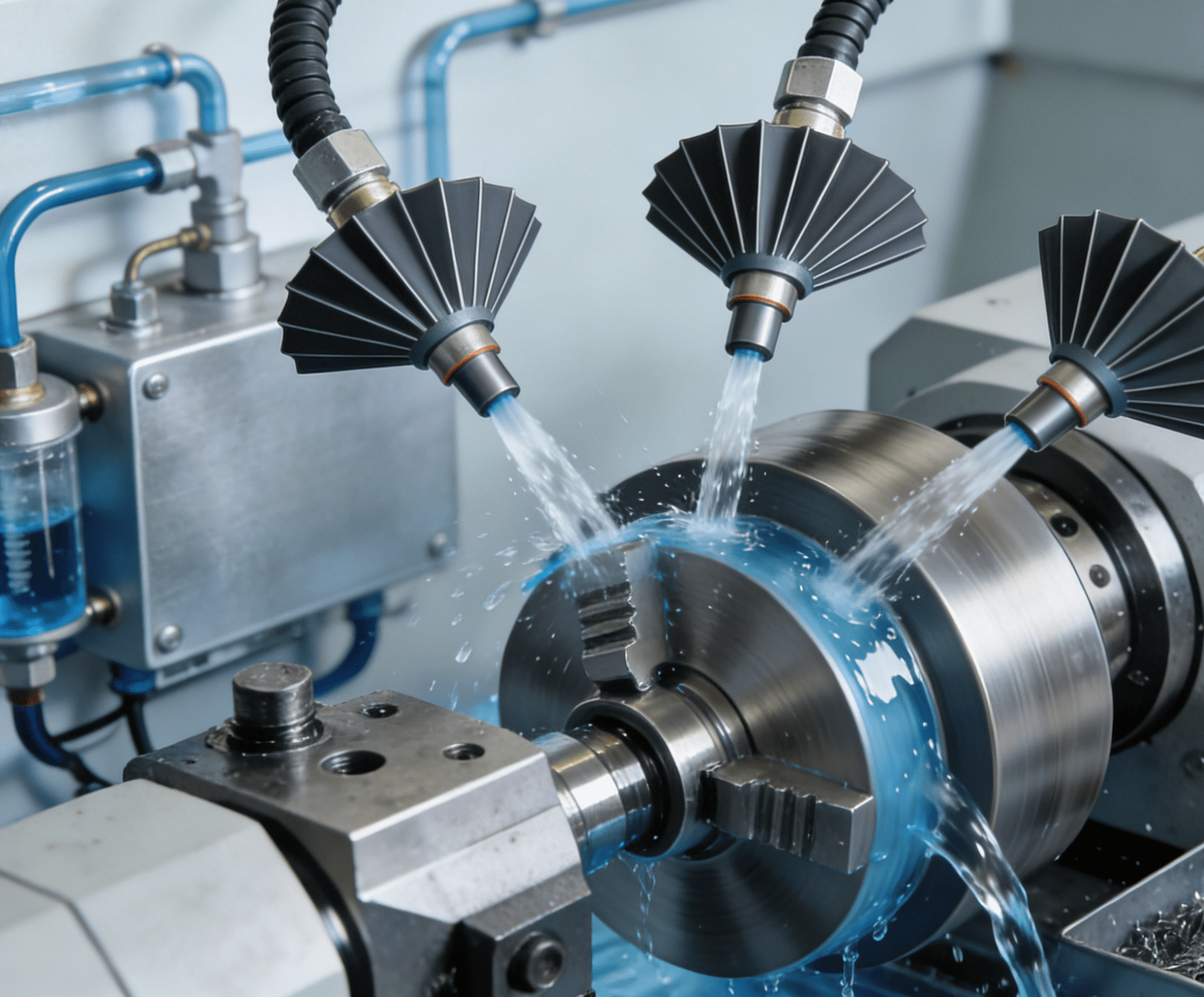

In high-speed milling technology, the intelligent system is the core for achieving precise control of higher spindle speed and smaller cutting depth. Specifically, advanced intelligent algorithms analyze the machining status in real time and dynamically adjust the spindle drive signal to ensure stable operation even at extremely high rotational speeds of tens of thousands of revolutions per minute. Meanwhile, for the setting of micron-level cutting depth, the intelligent system realizes ultra-fine adjustment of tool feed through the coordinated work of high-resolution feedback devices and precision servo drives. This precise dual control allows the tool to cut across the workpiece surface with a minimal cutting amount and a very high linear speed, effectively reducing cutting force and thermal deformation, and laying a crucial foundation for ultimately achieving excellent machining accuracy and surface finish.

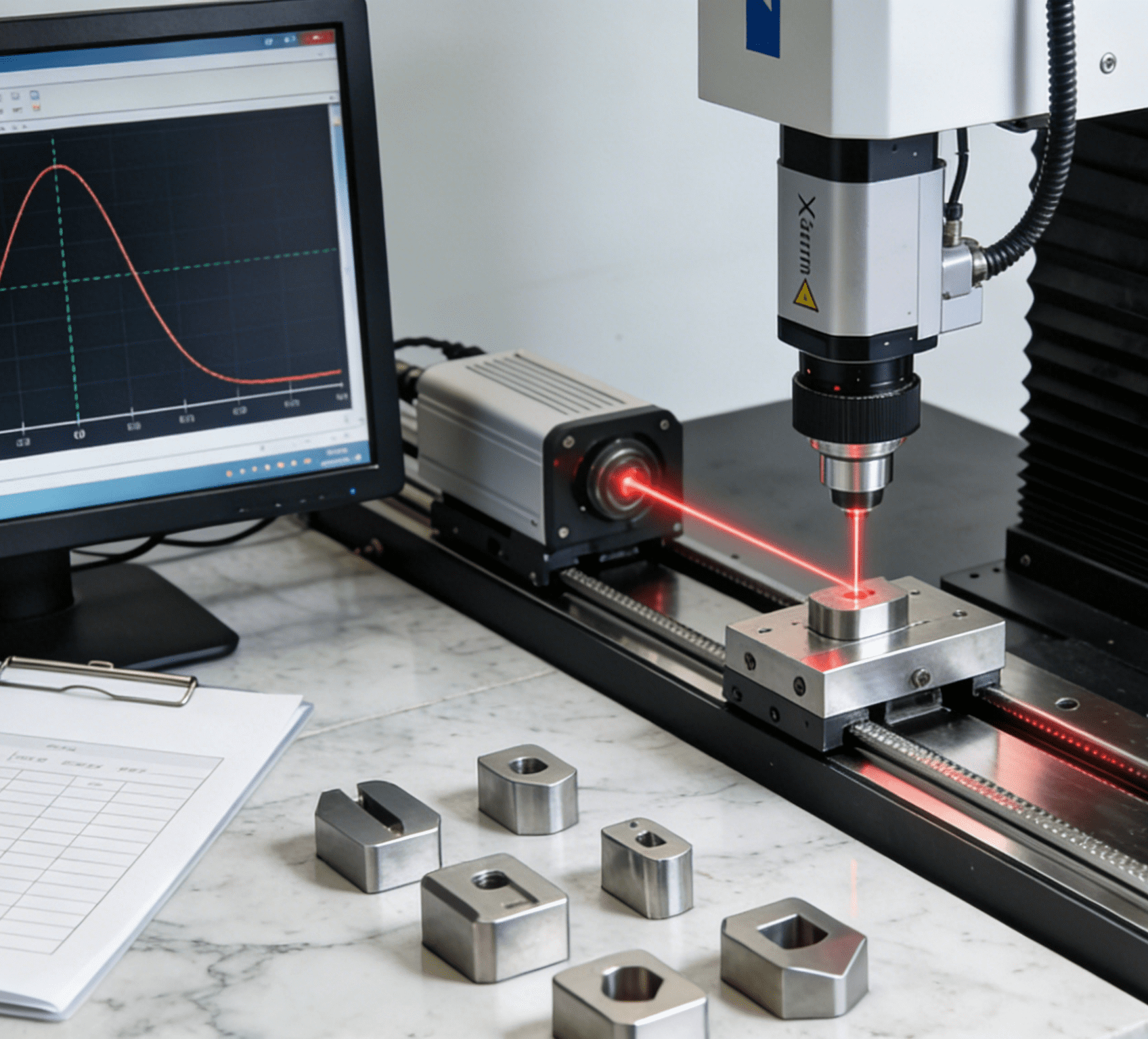

Tool Monitoring for Efficiency Improvement

In high-speed milling technology, after the intelligent system optimizes the spindle speed and cutting depth through intelligent control strategies, tool monitoring becomes a key link to improve overall efficiency. By using real-time sensors to monitor the temperature, vibration, and wear status of cutting tools, the system can quickly identify potential failures. For instance, when abnormal signals are detected, it can automatically adjust machining parameters or issue early warnings. This not only reduces unplanned downtime but also extends the service life of cutting tools, thereby significantly improving the precision and output efficiency of precision machining. Industry practices show that the integration of such monitoring technologies shortens the machining cycle by 15%-20% while avoiding quality fluctuations caused by tool failure.

Notably, the high-precision parts processed by high-speed milling technology often require matching intelligent assembly solutions to maintain overall production precision and efficiency, and 4-axis robot automatic assembly equipment plays a vital role in this link. These equipment, with their high positioning accuracy and flexible movement capabilities, can achieve seamless connection with high-speed milling processes. They can accurately grasp and assemble the micron-level precision parts machined by high-speed milling, and through collaborative control with the intelligent machining system, form a “machining-assembly” integrated intelligent production chain, further amplifying the efficiency and precision advantages of high-speed milling technology.

The breakthrough progress of high-speed milling technology is fully realized through the intelligent control of intelligent systems. With the above-mentioned technologies, intelligent systems achieve precise coordinated adjustment of spindle speed and cutting depth, making it possible to control micron-level cutting depth while pursuing higher machining efficiency. This not only significantly improves the surface accuracy and dimensional consistency of workpieces but also effectively extends the service life of cutting tools. The intelligent tool monitoring and process feedback mechanism ensure the stability and reliability of the machining process. Ultimately, the integration of these core elements enables modern manufacturing to stably produce precision components that meet stringent requirements in shorter cycles, providing solid technical support for the high-end manufacturing field.