Since launching the construction of “zero-waste cells“, Hefei has successfully built 79 “zero-waste factories”, covering key industries such as electronics, automobile, and new energy.

Since initiating the construction of “zero-waste cells”, Hefei has successfully completed 79 “zero-waste factories”, spanning multiple key sectors including electronics, automotive, and new energy. These factories have established a green production model featuring efficient resource recycling and waste reduction at the source, injecting new impetus into the city’s sustainable development.

Green Production and Source Reduction

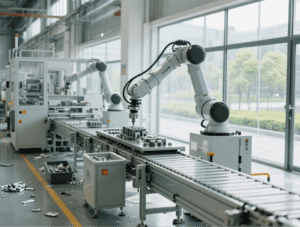

Through technological innovation and refined management, the generation of solid waste and resource waste has been significantly reduced. In the electronics manufacturing industry, the high-precision operation of Automatic placement machines not only improves the efficiency of component assembly but also reduces the loss and discarding of electronic components by optimizing the accuracy of material grabbing and usage, thereby achieving resource conservation at the front end of production. Volkswagen (Anhui) Co., Ltd. has eliminated plastic packaging for 170 parts and changed the filling method of raw materials such as antifreeze. As a result, it reduces the use of 30 tons of plastic packaging annually and cuts down the generation of over 300 hazardous waste barrels. The “paperless supermarket” in the final assembly workshop saves 282,250 sheets of paper each year. Foggini (Anhui) New Material Co., Ltd. has strengthened the whole-process refined management of hazardous waste. By precisely controlling raw material proportioning, regulating the frequency and water consumption of flushing equipment during production, and reusing flushing water, it has managed to reduce the generation of hazardous waste by 71% year by year from source control to production process management. This saves the enterprise 500,000 yuan in hazardous waste disposal fees annually and significantly reduces operational costs.

Resource Recycling and Turning Waste into Treasure

Efforts have been made to build internal recycling chains and improve the utilization of solid waste. Lujiang Longqiao Mining Co., Ltd. has constructed a tailings comprehensive utilization production line. It uses fine tailings from mineral processing to produce ultra-fine admixtures, which are used as raw materials for cement mixtures, concrete admixtures, and high-pressure pipe piles. This converts tailings into green building materials and promotes the technology of backfilling goafs with tailings, achieving a resource utilization rate of 95%. Lenovo (Hefei) Electronics Technology Co., Ltd. has established a systematic management mechanism for its main waste—raw material product packaging. By formulating a waste circular economy plan with local suppliers, some packaging materials are reused between suppliers and Lenovo Technology. Meanwhile, the company conducts meticulous classification, sorting, utilization, and disposal of waste internally, achieving a comprehensive utilization rate of 99%.

Chain Collaboration and Waste Regeneration

Cross-enterprise waste resource utilization is promoted to build a collaborative green development industrial chain. The waste glass generated during production by Corning Display Technologies (Hefei) Co., Ltd. is partly sent back to glass furnaces for reuse in production, and partly handed over to professional glass recyclers for processing into recycled materials, which can be used in manufacturing building materials. The annual resource utilization volume exceeds 10,000 tons, reintroducing “resources in the wrong place” into the economic cycle. Anli Material Technology Co., Ltd. has joined hands with upstream and downstream enterprises in the supply chain to actively develop and apply recycled polyurethane synthetic leather and composite materials, successfully realizing high-value-added conversion of solid waste. In 2025, the company’s “key technology for water-based solvent-free polyurethane composite materials” was successfully selected into the first batch of advanced and applicable technologies recognized by the Ministry of Industry and Information Technology, becoming the only enterprise in the same industry nationwide to be selected.

The practice cases of “zero-waste factories” show that industrial development and environmental protection are not mutually exclusive. Through technological and model innovation, it is entirely possible to achieve a win-win situation in both “economic accounts” and “environmental accounts”. As more enterprises join this green transformation, Hefei is accelerating its march towards a new path of industrialization characterized by resource conservation and environmental friendliness, laying a solid ecological foundation for the high-quality development of the city.

Six feeding systems for automatic assembly

What are the commonly used reclaiming mechanisms in automatic assembly?