- The Whole Province Makes Efforts: Taking Pilots and Innovations as the Starting Points to Build a Leading Edge in Smart Construction

In recent years, Guangdong Province has deeply studied and implemented the spirit of the 20th National Congress of the Communist Party of China, and thoroughly implemented the important speeches, instructions of General Secretary Xi Jinping during his inspection in Guangdong and the important expositions of General Secretary Xi Jinping on urban work. It has taken the development of smart construction as an important starting point to promote the transformation and upgrading of the construction industry, focused on key points such as policy

coordination, industrial agglomeration, innovation – led and integrated development, and guided smart – construction pilot cities to cultivate leading edges such as a full – chain industrial ecosystem, the integrated development of the information industry, and the innovative application of construction robots. Up to now, the province has released 42 provincial – level smart – construction pilot projects and 138 typical cases of innovative services of new technologies and products in smart construction. Three projects have been listed as national smart – construction pilot projects, and a total of 55 experience – based practices have been included in the list of replicable experience – based practices of the Ministry of Housing and Urban – Rural Development and promoted nationwide, with the quantity remaining ahead in the country.

- Guangzhou’s Experience: Dual – Driven by Policy Guidance and Technical Specifications to Solve the Problem of Smart – Construction Implementation

Guangzhou’s experience and practices in policy – planning formulation, modular – building incentives, bidding – technology application, pilot – standard refinement, technical evaluation, and case promotion have been promoted nationwide.

Improved policy system: Issued medium – and long – term plans such as the “Implementation Plan for Guangzhou as a Smart – Construction Pilot City” and the “Five – Year Action Plan for Accelerating the New – Type Building Industrialization in Guangzhou (2024 – 2028)” to clarify the development path; required that no less than 15% of the area of urban – village renovation and public – rental – housing projects adopt modular buildings, and took the lead in the country to give a 6% area reward (three projects have already obtained an incentive area of 2,455.92 square meters); included smart – construction technical requirements in the bidding documents of key projects and planned to incorporate them into the bid – evaluation method.

Rich technical system: Released a series of standards such as the “Construction Regulations for Industrialized Buildings” and the “Evaluation Guidelines for Smart – Construction Projects” to standardize the promotion of technologies; provided a basis for technical optimization by tracking pilot applications through regular evaluations, on – site observations, and exchanges; released 64 typical cases to help with the transformation of achievements and industry progress.

- Shenzhen’s Experience: Full – Chain Layout and Ecological Construction to Create a High – Ground for the Smart – Construction Industry

Shenzhen’s experience and practices in the five major measures of pilot – tracking, technology – promotion, standard – introduction, industrial – chain construction, and talent – cultivation have been promoted nationwide.

Pilot and technology – promotion: Cumulatively cultivated 124 smart – construction pilot projects, released 36 new – technology cases (8 of which were selected by the Ministry of Housing and Urban – Rural Development), and updated the technology catalog to the third edition (covering 47 technologies in seven major sections).

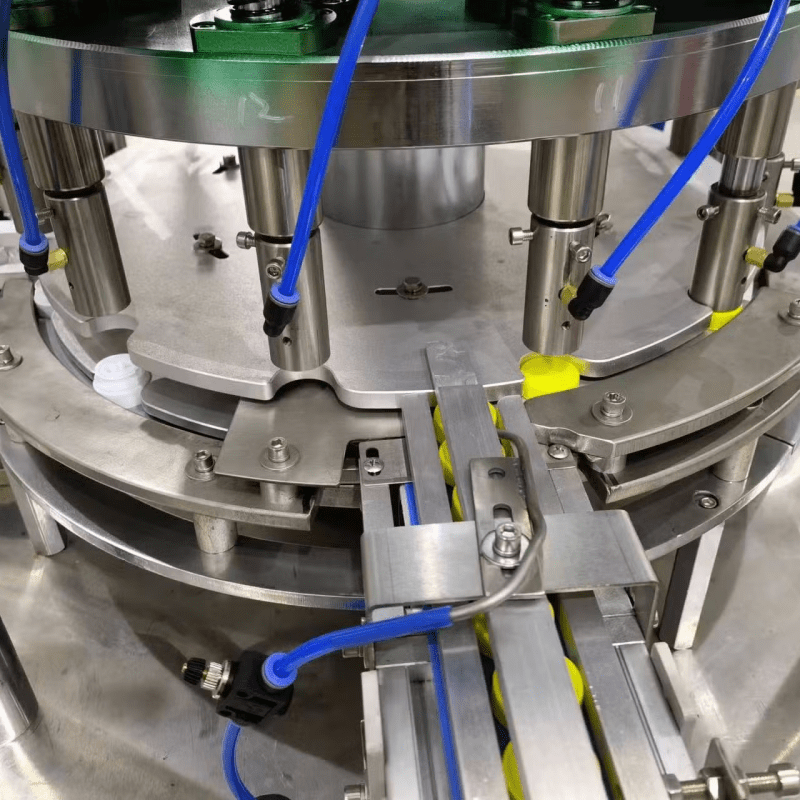

Standard and pricing innovation: Issued the “Supplementary Sub – items for Construction Robots (Trial)” to clarify the calculation method of use costs and provide a pricing basis for the application of construction robots.

Industrial – chain and ecology: Focused on developing six characteristic industrial chains and released 40 industrial – chain enterprises; established the Low – Altitude Economy Alliance, the Guangdong – Hong Kong – Macao Industrial Alliance, and the first national smart – construction society to promote industrial integration.

Talent – cultivation: Trained ten thousand industrial workers relying on 10 training bases, carried out “Science Popularization into Campus” covering nearly a thousand students, and held the “Shenzhen Craftsman Cup” competition to improve professional skills.

Foshan’s Experience: Coordination of Policy, Industry, Technology, and Talent to Consolidate the Foundation for the Development of Smart Construction

Foshan’s experience and practices in policy – system, industry – cultivation, technology – application, and talent – cultivation have been promoted nationwide.

Policy and pilot – cultivation: Issued the “Work Plan for Foshan as a Smart – Construction Pilot City” and released three technical standards; promoted the “New Urban Construction” pilot, built a CIM basic platform; selected 30 pilot projects and 16 leading enterprises, and gave integrity – points addition and capital – reward subsidies.

Technical evaluation and management: Innovatively introduced the “Evaluation Guidelines for the Smart – Construction Level of Municipal Infrastructure Projects”, established a “pilot – evaluation – promotion” closed – loop, and 9 excellent projects received points – addition incentives.

Industry and talent: Established a smart – construction industry association to promote industrial – chain coordination; improved the talent – echelon construction through skill competitions, seminars, and special training, and promoted high – quality development through multiple measures.

Automatic Assembly Machine in “Craftopia”

The Industrial Chain Driven by the Automatic Assembly Machine in “Craftopia”