In 1983, Epson launched its first SCARA robot, the SSR-H series, for commercial sale, marking the beginning of its journey in the robotics field. Over more than four decades, Epson has grown into a global leader in the robotics industry through its profound technical accumulation and relentless spirit of innovation, particularly excelling in the SCARA robot sector—ranking first in global sales in 2024. The success of Epson Robots stems from its unique technical philosophy of “Mizuho, Komaru, Seimitsu” (saving energy, being compact, and achieving precision), which permeates product research, design, and application, injecting strong momentum into the transformation and upgrading of global manufacturing.

Innovative Technologies Forge Outstanding Performance

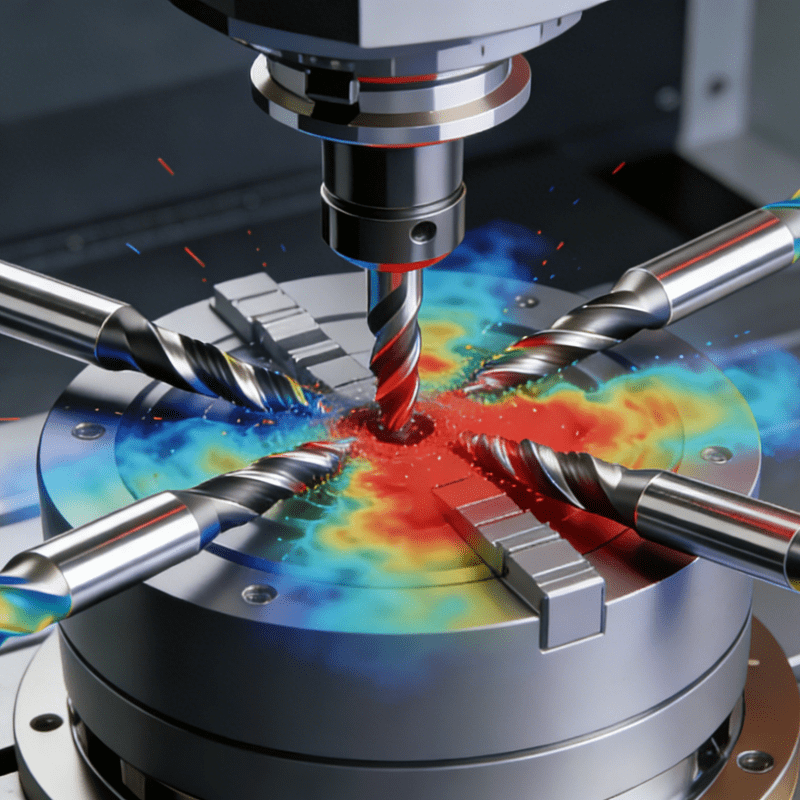

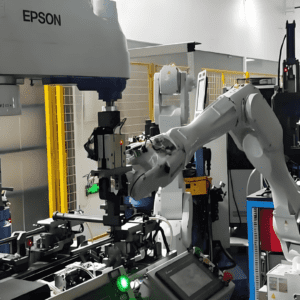

Epson Robots’ exceptional performance is built on a suite of advanced technologies. Pressure sensors, as key components, endow the robots with precise operational capabilities, featuring five core “skills”: contact detection, alignment, probing, tracking, and pressing. In precision assembly tasks, pressure sensors can accurately perceive and control force, transforming previously manual high-difficulty operations into stable, precise, and efficient automated processes. They also boast high sensitivity to detect minute changes, high rigidity to handle a wide force range, and high integration to simplify complex operations—significantly enhancing the robot’s performance in intricate tasks.

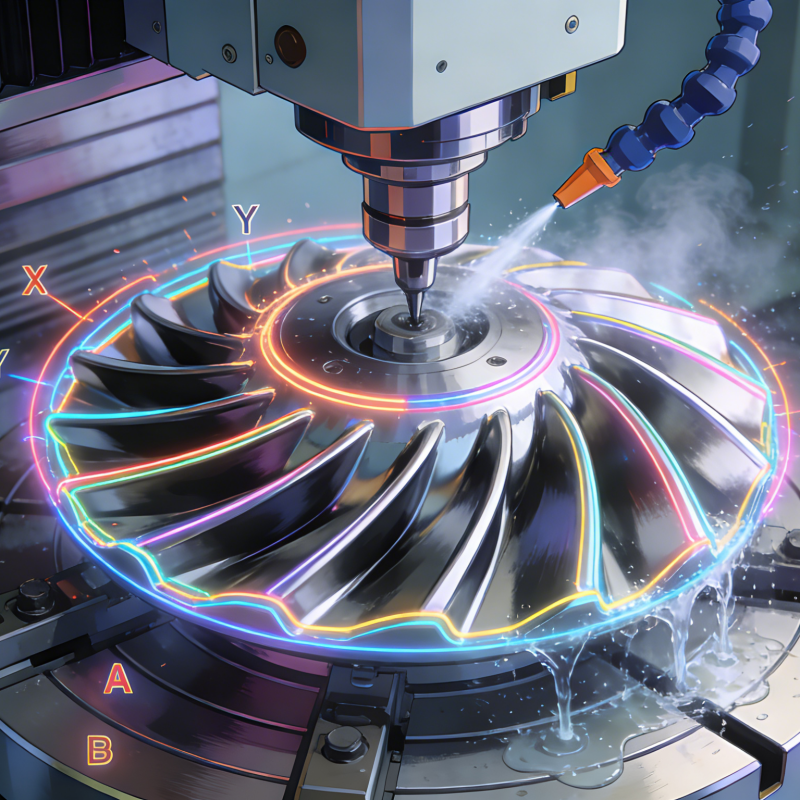

In high-speed motion scenarios, Epson’s proprietary GYROPLUS Technology plays a pivotal role. Derived from Epson’s extensive experience in manufacturing high-quality quartz crystal materials, this technology combines quartz crystal expertise with proprietary micro-electro-mechanical systems (MEMS) manufacturing processes. Applied to sensing devices, it has led to the development of compact, high-performance quartz gyroscope sensors. Equipped with a “double-T” crystal oscillator configuration, these sensors offer excellent vibration and shock resistance, as well as high-temperature stability. Paired with intelligent control algorithms, GYROPLUS Technology can real-time suppress micro-vibrations during robot movement, achieving shorter settling times and higher positioning accuracy. This means Epson Robots can maintain stable precision and repeatability at high speeds without sacrificing speed or load, significantly boosting production efficiency and reducing costs.

Diverse Products Meet Multifaceted Needs

After years of development, Epson has built a rich and diverse robot product portfolio. Take SCARA robots, for example: the G10 series is designed for high-load applications, capable of handling a maximum weight of 10kg, suitable for multi-fixture high-speed assembly and supporting packaging operations. It offers multiple installation methods—tabletop, ceiling, and sidewall. Some models in this series comply with ISO cleanroom and ESD standards, meeting the stringent requirements of semiconductor and electrostatic-sensitive applications.

Six-axis robots also perform brilliantly. The VT series, featuring next-level technology, includes the VT6L—a product integrating numerous advantages with a built-in controller and a hollow arm design to simplify wiring, boasting a compact structure. It also offers optional cleanroom and IP-rated models, suitable for various simple application scenarios. The N series, the world’s first folding-arm six-axis robot, was developed to efficiently utilize workspace. It optimizes motion efficiency, shortens cycle times, reduces elbow interference, and enhances maneuverability in confined spaces—providing significant advantages in space-constrained production environments.

Wide-Ranging Applications Empower Industries

Epson Robots are widely used across numerous industries, providing strong support for their intelligent transformation. In automotive manufacturing, they participate in multiple processes such as mirror/glass assembly, headlight and taillight assembly and testing, transmission and clutch assembly, fuel injector assembly, instrument panel assembly, and engine hood and trunk lock assembly—improving assembly precision and efficiency while ensuring product quality. In consumer goods manufacturing, from home appliance assembly to the production of small appliances like electric toothbrushes and chainsaws, to speaker manufacturing, weed trimmer assembly, and connector assembly, Epson Robots meet the diverse and large-scale production needs of consumer products with their high precision and speed.

In industrial product manufacturing, they assist in tasks such as casting machine loading/unloading, smoke detector assembly, fiber optic connector assembly, light bulb assembly, and hydraulic valve testing. In the electronics industry, they are used for PC board inspection and automatic cleaning of circuit board components. In telecommunications, they participate in the assembly and testing of mobile phones and radios. In pharmaceuticals, they handle custom prescription drug filling, tablet packaging, and protein crystal structure analysis. In the solar energy sector, they enable panel assembly. In packaging, they perform meat packaging, box cutting and strapping, plastic part packaging, straw packaging, and product packaging. In semiconductor manufacturing, they undertake key tasks such as custom chip assembly and testing, wire bonding, automatic circuit board testing, and aerospace electronic component assembly. In the food industry, they are involved in meat processing, vegetable picking and cutting, and product packaging.

Deep Roots in China: Customized, Innovative Products

As a global manufacturing powerhouse, China is a key market for Epson Robots. On August 9, 2025, Epson held a launch event in Shenzhen, unveiling the LA-A series—its first industrial robot custom-developed for the Chinese market—demonstrating its emphasis on China and its in-depth localization strategy. Epson’s Shenzhen factory, a crucial global R&D and production base since its establishment in 1985, has been closely linked to China’s manufacturing industry, serving enterprises in semiconductor, automotive parts, new energy, 3C electronics, and other fields. Over 50% of SCARA robots produced by Epson’s global factories are sold in China.

The LA-A series integrates Epson’s “Mizuho, Komaru, Seimitsu” technical genes with localized innovation. It features core advantages of “high efficiency and energy saving, compactness and flexibility, precision and reliability.” Its innovative energy-saving design achieves a standard cycle time of only 0.404 seconds and a power consumption as low as 0.8kVA—saving over 30% energy compared to traditional robots. With a body weight of just 12kg and a back wiring design, it fits into 600mm×600mm workstations, solving the space constraints in Chinese factories. The folding arm structure combines the flexibility of six-axis robots, shortening cycle times and improving production efficiency. With a repeat positioning accuracy of ±0.01mm and vibration suppression technology, it stably performs precision operations such as screw locking and component insertion at high speeds. To lower the barrier for Chinese customers, the supporting RC800-L controller features a Chinese programming interface and is compatible with HarmonyOS and mainstream bus protocols, enabling seamless integration with local production lines. The LA-A series, from project initiation to mass production in less than a year, reflects Epson’s ability to quickly respond to market demands in China.

Looking ahead, Epson will continue to uphold the “Mizuho, Komaru, Seimitsu” philosophy, continuously innovating technologies, enriching products, and expanding applications. It will deeply integrate into the intelligent development wave of China’s and global manufacturing industries, helping various sectors achieve higher-quality and more sustainable development amid the transformations of Industry 4.0 and Industry 5.0, and continuing to write a chapter of innovation in the robotics field.