Advanced technologies are rapidly transforming every corner of the electronics industry, and at the heart of this evolution lies a critical tool: automatic assembly machines for electromechanical components. From the earliest radio tubes to today’s nanoscale processors, these automated systems have enabled unprecedented precision, speed, and scalability in producing the electromechanical parts that power our smartphones, computers, and smart devices. Let’s explore how electromechanical component assembly automation has evolved, the role of industry leaders in advancing it, and the trends shaping its future.

The Evolution of Electromechanical Component Assembly: From Manual to Automated

The story of electromechanical component production began with manual labor. In the early 20th century, radio tubes, triodes, and basic circuit components were assembled by hand, limited by small production volumes. But as demand for consumer electronics grew, the industry shifted to mass production—and automation followed.

By the 1930s, assembly lines (like RCA’s radio tube factories) were churning out over 15,000 components daily, with specialized machines automating single operations to boost accuracy and speed. The 1970s and 1980s marked a shift toward integrated automated assembly systems, where robotics and measuring instruments handled entire production stages, from soldering to quality checks.

The 1990s and 2000s brought a revolution: nanotechnology. Suddenly, automated assembly machines could produce chips and electromechanical components with nanometer-scale precision, packing more power into smaller sizes. Innovations in materials—silicon-on-insulators, GaN, and graphene—further pushed the limits, requiring automated systems to adapt to new substrates and tighter tolerances.

Today, electromechanical assembly automation is defined by smart, adaptive machines that handle everything from micro-connector insertion to sensor calibration, laying the groundwork for the next wave of electronic innovation.

Apple’s Role: Catalyzing Advances in Electromechanical Assembly Automation

While Apple is known for its consumer devices, its greatest impact on the electronics industry lies in driving progress in manufacturing—including electromechanical component assembly. The company’s demand for smaller, more powerful, and reliable devices has forced suppliers to adopt cutting-edge automated assembly technologies.

Take the first iPhone (2007) and iPad (2010): these devices required miniaturized electromechanical components (e.g., touch sensors, battery connectors, and micro-motors) that could only be produced at scale with advanced automated systems. To meet Apple’s standards, suppliers like TSMC, Samsung, and Foxconn accelerated investments in high-precision electromechanical assembly machines. For example, the 10nm chips in the 2016 iPhone 7 lineup demanded automated systems with sub-micron accuracy—years before most competitors adopted 14nm processes.

Apple’s investments in R&D—from MEMS (Micro-Electro-Mechanical Systems) to lithium-polymer battery components—also spurred innovation in automated assembly. The company’s focus on quality and efficiency pushed suppliers to develop flexible automated assembly lines that could switch between component types quickly, supporting Apple’s rapid product iteration. As analysts at Digitimes note, these advancements rippled through the industry, making Apple an “engine of progress” for electromechanical manufacturing automation.

Modern Trends: Smart Factories and AI-Driven Electromechanical Assembly

Today, survival in the electronics industry depends on state-of-the-art electromechanical assembly automation. Industry leaders like Foxconn, Quanta Computer, and Pegatron now deploy hundreds of thousands of industrial robots (from Kuka, ABB, and Fanuc) alongside specialized automatic assembly machines for electromechanical components. These systems don’t just assemble parts—they optimize factory logistics, track component flows, and self-calibrate to maintain precision.

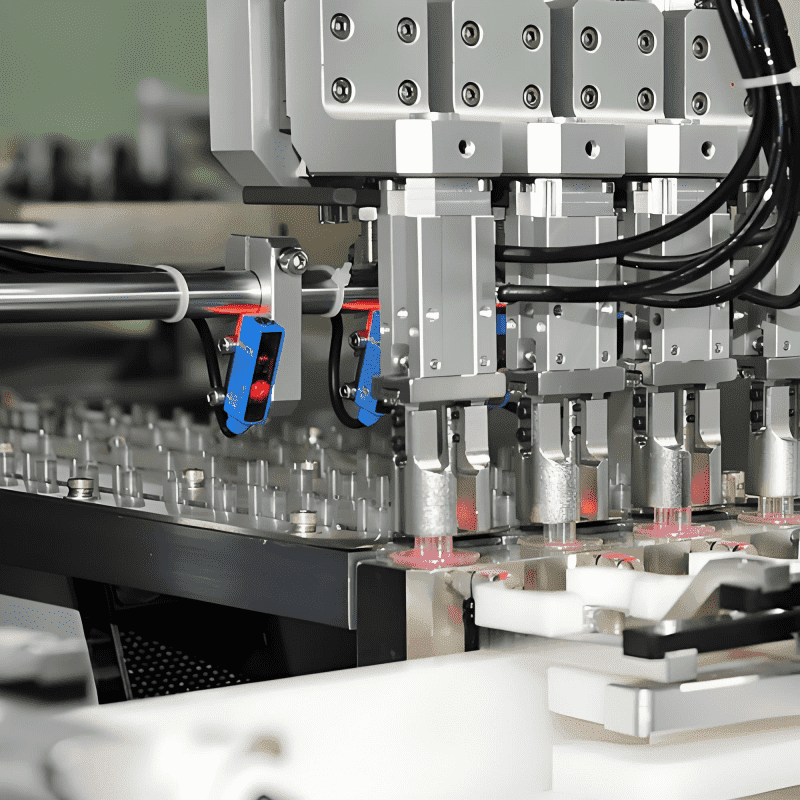

Among these specialized setups, the 4-Axis Robotic Vision-Guided Spring Placement System stands out for its ability to handle micro-scale springs—critical components in smartphones, automotive sensors, and medical devices—with unmatched precision. Equipped with high-resolution machine vision cameras, the system automatically identifies spring orientations, adjusts for minute positional deviations (as small as 0.02mm), and places each component with repeatable accuracy, eliminating the errors common in manual or semi-automated spring placement. By integrating 4-axis motion control, it also speeds up cycle times by 30% compared to traditional 3-axis systems, making it ideal for high-volume production where spring alignment directly impacts the performance of electromechanical devices.

Key trends shaping the space further include:

AI and Machine Vision: Beyond spring placement, automated assembly machines now use AI-powered vision systems to inspect all types of electromechanical components in real time, detecting defects as small as 0.1 microns. This reduces error rates by up to 90% compared to manual inspection.

IoT-Connected Assembly Lines: Sensors in assembly machines (including 4-axis robotic systems) transmit data on performance, component availability, and maintenance needs, enabling predictive upkeep and minimizing downtime.

Flexible Automation: Modern systems—from spring placement robots to chip assemblers—support quick reconfiguration (e.g., switching from automotive sensors to smartphone connectors in hours), critical for high-mix, low-volume production.

Smart Factories: Integrated ecosystems where AI analyzes data from assembly machines, supply chains, and demand forecasts to optimize production schedules—boosting efficiency by 40% or more.

The Future: 3D Printing, Flexible Electronics, and Beyond

The next decade will redefine electromechanical component assembly. 3D printing is poised to transform small-batch production, with automated systems printing complex electromechanical parts (e.g., micro-actuators) in hours, slashing lead times and costs.

Flexible electronics—using organic semiconductors and nanomaterials—will demand new automated assembly machines capable of handling bendable substrates without compromising precision. Meanwhile, neuromorphic processors (modeled after the human brain) will require assembly systems with unprecedented accuracy, as their intricate structures push the limits of current automation.

Conclusion

From manual radio tube assembly to AI-driven smart factories, automatic assembly machines for electromechanical components have been the backbone of electronics innovation. Industry leaders like Apple have accelerated this progress, pushing suppliers to adopt ever-more advanced automation—including specialized solutions like the 4-Axis Robotic Vision-Guided Spring Placement System. As 3D printing, flexible electronics, and AI continue to evolve, these machines will remain critical to producing the smaller, smarter, and more reliable electromechanical components that power our connected world.

For manufacturers looking to stay competitive, investing in cutting-edge electromechanical assembly automation isn’t just an option—it’s a necessity.

What is the market size and development trend of medical product assembly machines?

What are the advantages of medical product assembly machines?