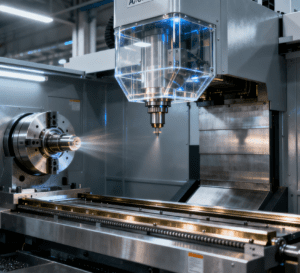

In the field of precision manufacturing, “millimeter-level precision” can no longer meet the demand. From aero-engine blades and medical device artificial joints to complex cavities of automotive molds and microstructures of electronic components, all require “micron-level” machining precision. However, the traditional machining mode has long been trapped by three major challenges: complex parts require multiple clamping operations, leading to accumulated precision errors; switching between multiple processes wastes a lot of production time; and machining at special angles requires custom fixtures. The 5-axis machining center, with its core capabilities of “multi-axis linkage, one-time forming, and stable high-precision output”, has become a key piece of equipment to break through these bottlenecks.

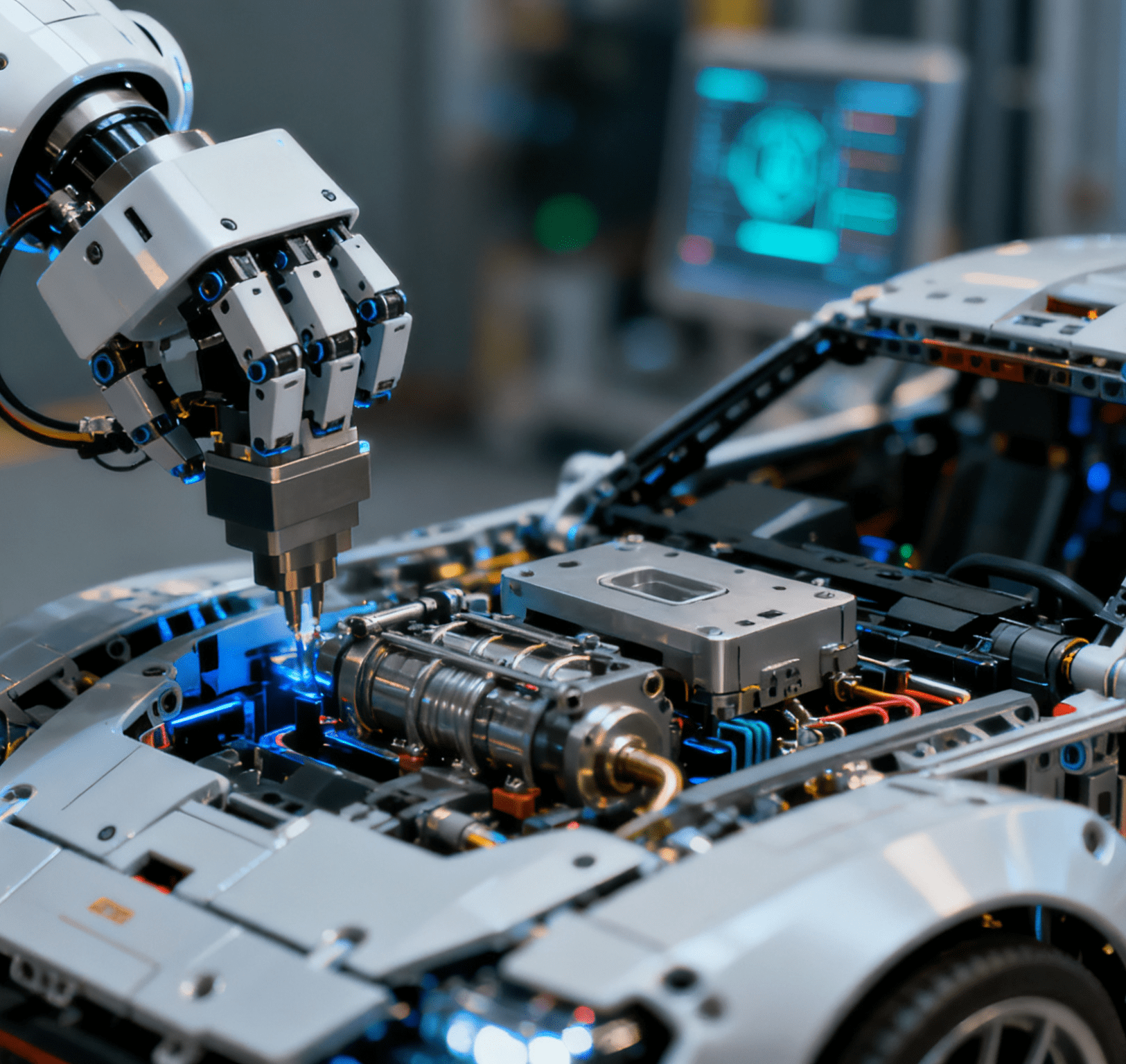

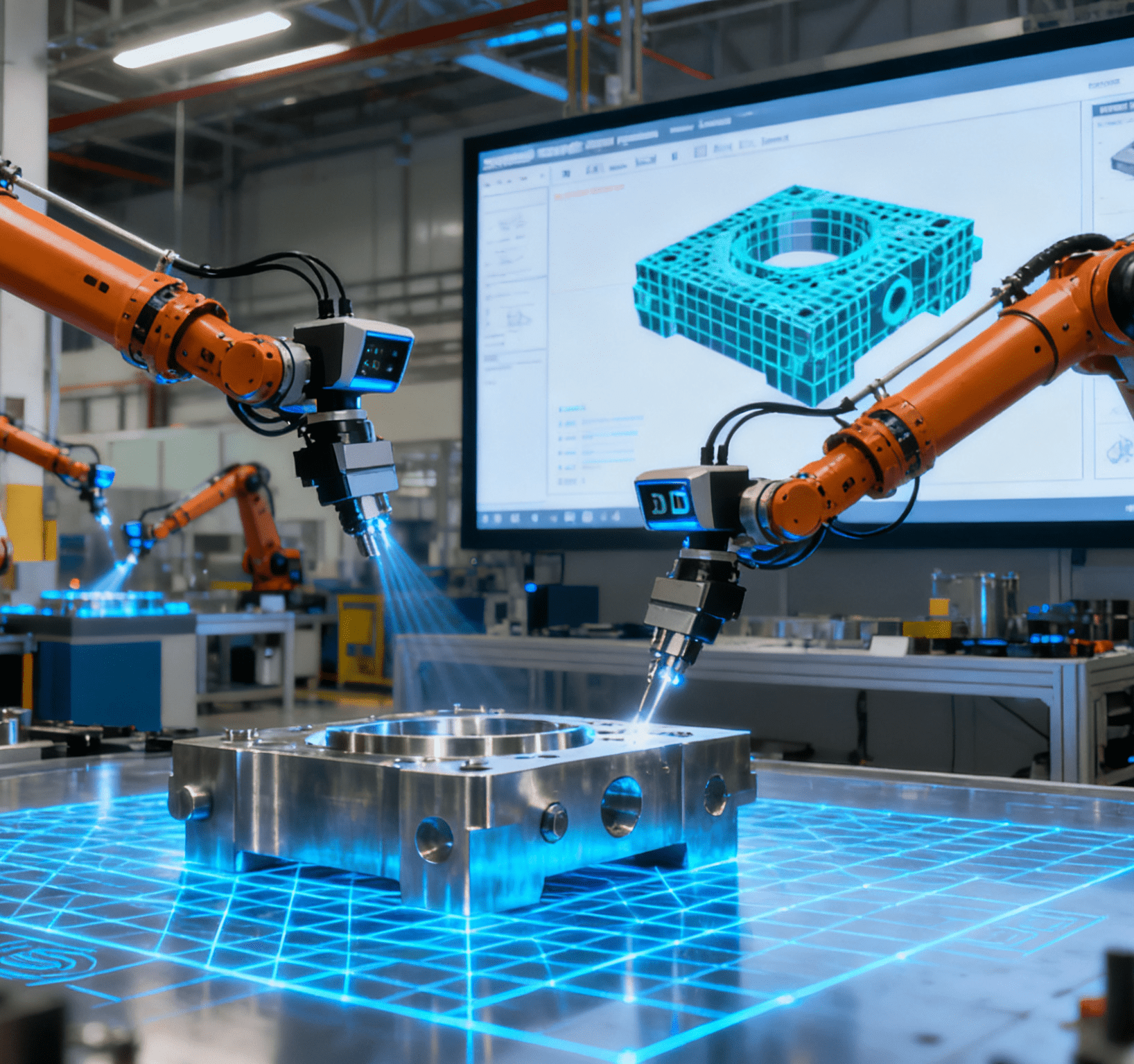

Notably, to further maximize the efficiency and precision advantages of 5-axis machining centers—especially in scenarios involving large-batch, thin-walled flat workpieces like automotive mold inserts or electronic component substrates—many enterprises have paired them with Automated Flat Sheet Handling Systems. These systems integrate robotic arms, vacuum suction cups, and intelligent positioning sensors to automatically complete the entire process of loading raw flat sheets (such as aluminum alloy plates, carbon fiber sheets) into the 5-axis machining center, transferring semi-finished products between processes, and unloading finished parts. By eliminating manual handling that may cause workpiece deformation or position deviation, they not only avoid precision losses caused by human interference but also reduce the workpiece transfer time between machining steps by over 40%. For example, an automotive mold enterprise previously spent 15 minutes manually loading/unloading each flat mold blank; after matching with the Automated Flat Sheet Handling System, the process was shortened to 2 minutes, and the consistency of blank positioning accuracy was improved from ±0.01mm to ±0.003mm, perfectly complementing the 5-axis machining center’s high-precision and high-efficiency characteristics.

Breaking Traditional Bottlenecks: Precision & Qualification Rate Leap

From the perspective of enterprise production pain points, the limitations of traditional machining equipment have long restricted development. An aviation component enterprise once needed to use a vertical milling machine and a horizontal lathe for 5 clamping operations to machine a curved blade. Each clamping required re-calibration of the reference, and the final product precision could only reach 0.02mm with a qualification rate of less than 70%. A medical device factory had to customize 3 sets of special fixtures for machining artificial hip joints due to the need for multi-angle machining of the spherical arc. This not only incurred high costs but also prolonged the production cycle to 15 days per piece.

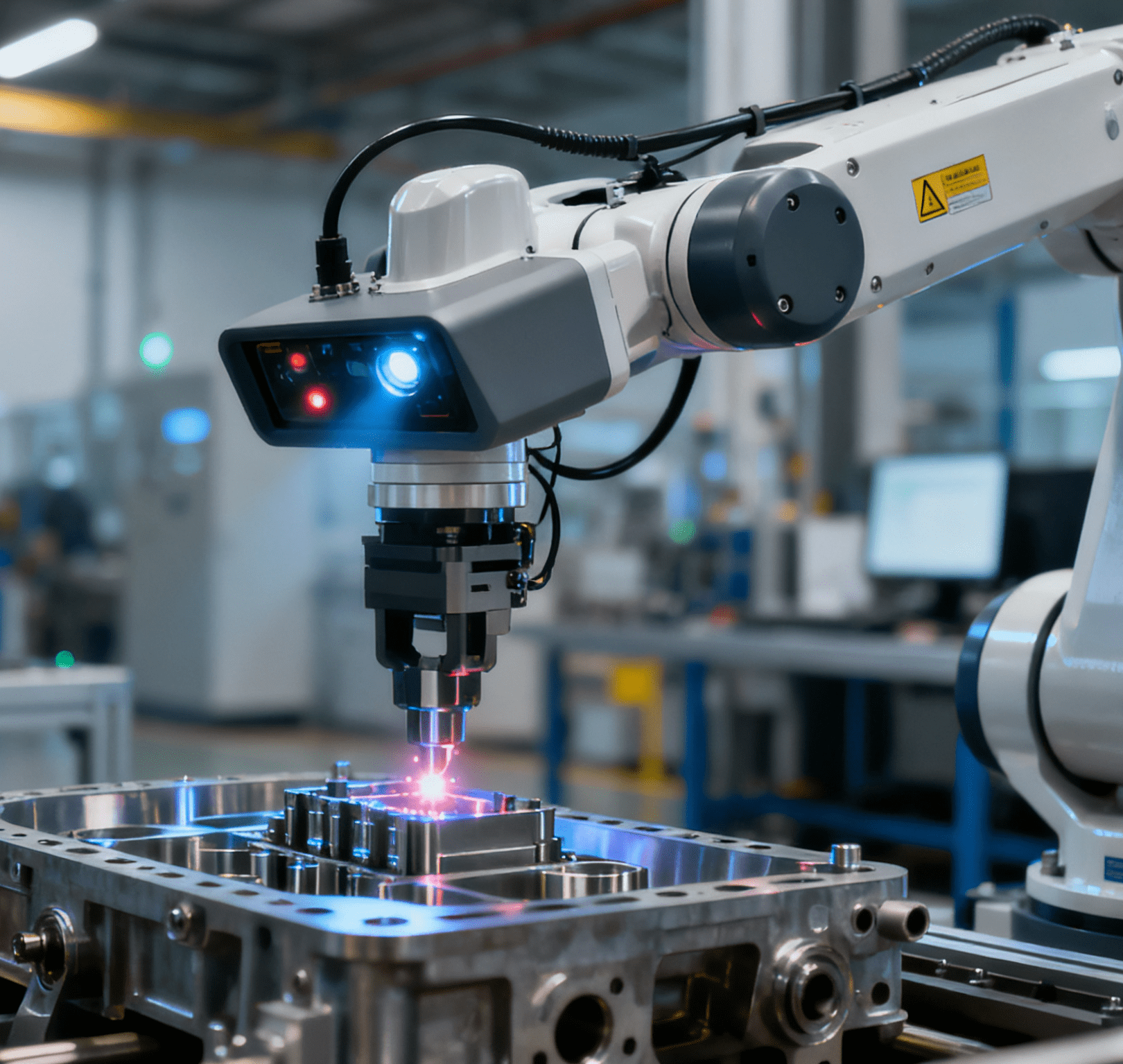

In contrast, through the linkage control of “X, Y, Z three-axis linear motion + A, C two-axis rotational motion”, the 5-axis machining center can achieve “all-round wrap-around machining” of parts. Taking an aviation blade as an example, only one clamping and fixing is required, and the system can automatically complete all processes such as curved surface milling, chamfering, and drilling, avoiding the superposition of clamping errors. The finished product precision can be stably controlled within 0.005mm, and the qualification rate is directly increased to over 98%.

Efficiency & Flexibility Upgrade: Adapting to Diverse Production Needs

More importantly, the 5-axis machining center can significantly improve the efficiency and flexibility of precision machining. When traditional equipment processes complex parts, process switching requires manual handling and repositioning, resulting in a single-shift output often less than 20 pieces.

In contrast, the 5-axis machining center automatically calls the tool library (which can hold 20-40 tools) through the numerical control system and automatically generates machining paths based on the 3D model of the part, enabling continuous multi-process machining without manual intervention. An automotive mold enterprise reduced the time to machine a set of new energy vehicle battery case molds from 72 hours to 24 hours after introduction, with single-shift output tripled. Meanwhile, it supports rapid production changeover: machining aluminum alloy molds in the morning and switching to carbon fiber parts in the afternoon by simply calling up new parameters—no fixture replacement needed, perfectly fitting multi-variety, small-batch precision machining demands.

Wide Application & Easy Implementation: Lowering Enterprise Adoption Barriers

From the perspective of practical application scenarios, the 5-axis machining center covers multiple precision manufacturing fields: it processes complex shaped parts like engine combustion chambers in aerospace (solving high-temperature alloy machining difficulties), machines titanium alloy artificial joints in medical care (ensuring biocompatibility), and produces micro-cavities for 5G filters in electronics (meeting high-frequency signal precision). An electronic component enterprise used it to machine a 10mm×8mm micro-sensor housing, achieving 0.003mm hole precision and avoiding thin-walled part deformation via a 15,000rpm high-speed spindle.

From the implementation perspective, its practicality is guaranteed: it connects with mainstream CAD/CAM software (e.g., UG, Mastercam) without replacing existing systems, and operators can master it after 1-2 weeks of training. For SMEs, small-to-medium 5-axis models (with the same footprint as traditional vertical milling machines) and flexible payment models (installment, lease-to-buy) reduce initial investment pressure. Core components (spindles, guide rails) also have a 3-year warranty, with regular supplier inspections controlling maintenance costs.

Against the backdrop of “Made in China 2025” promoting the upgrading of high-end equipment, the 5-axis machining center is no longer just a “symbol of high-end equipment” but a “necessity” for precision manufacturing enterprises to enhance their competitiveness. It can not only solve the current pain points of machining precision and efficiency but also help enterprises undertake high-value-added orders and seize high-end market share. For manufacturing enterprises pursuing “intensive cultivation”, introducing a 5-axis machining center is not only a practical choice to break through production bottlenecks but also an indispensable path to move towards a higher level of precision manufacturing.