Table of Contents

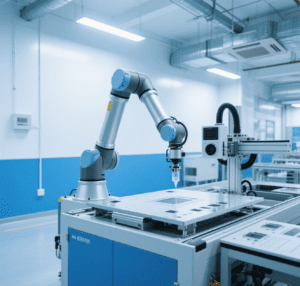

Toggle4-Axis Robotic Vision-Guided Dispensing System: Redefining Precision in Adhesive Application

In the landscape of precision manufacturing, adhesive dispensing for complex components—ranging from microelectronics to medical devices—requires unparalleled accuracy and consistency. Traditional manual or 2-axis dispensing systems struggle with slow cycle times (10–20 seconds per part), inconsistent bead profiles (±0.3mm errors), and limited adaptability to 3D surfaces. The 4-Axis Robotic Vision-Guided Dispensing System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive fluid control to enable micron-level precision in high-mix, high-volume production.

I. Core Technical Architecture: Speed Meets Micro-Precision

The system’s modular design synergizes robotic agility with intelligent control, comprising three interdependent subsystems:

1. High-Speed 4-Axis Robotic Manipulation

Powered by SCARA robots (e.g., Epson LS6, Yamaha YK-XG), the system delivers:

- Planar Motion Dominance: Achieves dispensing speeds of 200+ parts per minute with ±0.02mm repeatability, 3–5x faster than traditional systems;

- Adaptive Z-Axis Compliance: Servo-driven vertical stroke (up to 300mm) with force-torque sensors (0.1–5N feedback) adjusts to surface variations, ideal for non-planar dispensing;

- Lightweight Carbon Fiber Arms: Reduces inertia for rapid acceleration/deceleration, maintaining bead consistency at 1.5m/s traverse speeds.

2. AI-Vision Guided Dispensing Ecosystem

A dual-camera vision setup ensures sub-micron accuracy:

- Overhead 2D Camera: 12MP telecentric lens maps component features with 99.9% accuracy, correcting ±10mm positional deviations via YOLOv8-based algorithms;

- 3D Laser Profiler: Scans surface topography (up to 0.1mm resolution) to generate adaptive dispensing trajectories for curved or textured surfaces;

- Real-time Bead Inspection: Vision systems analyze adhesive bead width, height, and continuity during dispensing, rejecting non-conforming parts with 99.8% accuracy.

3. Intelligent Fluid Control Module

The dispensing end-effector combines precision mechanics with smart sensing:

- Multi-Mode Dispensing Nozzles: Pneumatic valves for low-viscosity liquids (1–100cP), piston pumps for pastes (100–10,000cP), and jet dispensers for micro-deposits (≤1nL);

- Pressure-Temperature Compensation: Real-time adjustment of dispensing pressure (0.1–10bar) and nozzle temperature (20–150°C) to maintain viscosity consistency;

- Quick-Change Tooling: Swaps between nozzle types in <15 seconds, supporting rapid transitions between epoxy, silicone, and UV-cure adhesives.

II. Industrial Applications: From Micro-Dispensing to Mass Production

1. Electronics & Semiconductor Manufacturing

- PCB Underfill Dispensing: Jet dispensers apply 50–100μm underfill beads around BGA packages with ±5μm accuracy, preventing thermal stress failures;

- Micro-LED Array Bonding: SCARA robots dispense 1nL adhesive dots for 0.1mm×0.1mm micro-LEDs, enabling 4K display pixel bonding at 1,000+ dots per second.

Case Study: A Taiwanese semiconductor foundry reduced underfill defects by 95% and increased production yield by 30% after deploying 25 systems, achieving 24/7 operation with <0.01% downtime.

2. Medical Device Fabrication

- Catheter Tip Sealing: Precision pneumatic dispensers apply medical-grade silicone around catheter tips (1–3mm diameter) with ±0.05mm bead control, ensuring hermetic seals;

- Implantable Device Encapsulation: 316L stainless steel nozzles and ISO 8 cleanroom compatibility for dispensing biocompatible adhesives on pacemaker components.

3. Automotive Electronics & EV Components

- Battery Pack Sealing: High-viscosity epoxy dispensing on battery casings (50–100mm bead length) with IP67-level precision, preventing electrolyte leakage;

- Sensor Encapsulation: Vision-guided dispensing of thermal interface materials on LiDAR sensors, maintaining ±0.1mm thickness for optimal heat dissipation.

III. Competitive Advantages Over Traditional Systems

| Performance Metric | Manual/2-Axis Dispensing | 4-Axis Vision-Guided System |

| Dispensing Speed (parts/min) | 30–50 | 150–200 |

| Bead Positioning Accuracy | ±0.3mm | ±0.02mm (X/Y), ±0.1mm (Z) |

| Viscosity Range Support | Narrow (1–1,000cP) | Broad (1–10,000cP) |

| 3D Surface Adaptability | Limited | Full (curvature radius ≥20mm) |

| Changeover Time | 15–30 minutes | <3 minutes (recipe-based) |

IV. Future Innovations

AI-Driven Process Optimization

- ML models analyze 100,000+ dispensing cycles to predict optimal pressure-viscosity curves for new adhesives, reducing setup time by 70%.

4D Vision & Dynamic Dispensing

- Time-of-Flight (ToF) sensors enable real-time compensation for thermal expansion (up to 0.2mm/m) in high-temperature environments like EV battery production.

Collaborative Dispensing Cells

- Dual-arm cobots (e.g., UR10e) with force feedback enable human-robot collaboration in medical device assembly, where manual inspection merges with robotic precision.

Conclusion

The 4-Axis Robotic Vision-Guided Dispensing System represents a paradigm shift in precision fluid application, addressing the critical needs for speed, accuracy, and flexibility in modern manufacturing. By merging SCARA robotics, AI vision, and adaptive fluid control, it enables manufacturers to tackle previously unfeasible micro-dispensing tasks while maintaining mass-production efficiency. As Industry 4.0 progresses, these systems will evolve into self-optimizing cyber-physical systems, ensuring every drop of adhesive is placed with unprecedented precision with minimal human intervention.

#4-Axis Robotic Dispensing System #Vision-Guided Adhesive Automation #Precision Fluid Dispensing Technology