Table of Contents

Toggle4-Axis Robotic Tray Loading System: Redefining Efficiency in Automated Material Handling

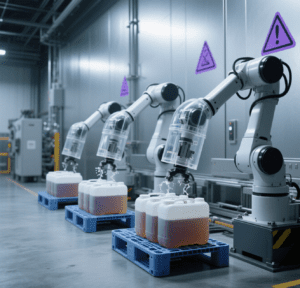

In the fast-paced world of modern manufacturing, the seamless loading of components into trays is the unsung hero of streamlined production. Whether in electronics, automotive, or pharmaceuticals, manual tray loading is a bottleneck—prone to errors, slow, and labor-intensive. Enter the 4-Axis Robotic Tray Loading System, a SCARA-based solution designed to transform this critical process. By merging high-speed motion, precision positioning, and intelligent adaptability, this system eliminates inefficiencies, boosts quality, and future-proofs production lines for high-mix, high-volume environments.

The 4-Axis Advantage: Engineered for Speed and Precision

Four-axis SCARA (Selective Compliance Assembly Robot Arm) robots are purpose-built for planar material handling, making them ideal for tray loading:

1. Lightning-Fast Cycle Times

With a rigid horizontal arm design and optimized joint mechanics, SCARA robots achieve pick-and-place speeds of up to 200 cycles per minute—3–5x faster than human operators. For a smartphone factory loading 100 tiny camera modules into trays, this reduces time from 5 minutes to just 90 seconds.

2. Micron-Level Placement Accuracy

A repeatability of ±0.02mm ensures components land exactly in tray slots, even for parts as small as 2mm or as delicate as OLED panels. This eliminates misalignments that cause downstream issues, such as damaged pins in automotive connectors or cracked glass in consumer electronics.

3. Cost-Effective Performance

Compared to 6-axis robots, 4-axis systems cut capital costs by 30–40% and reduce maintenance needs by 50%, thanks to simpler kinematics. For mid-sized manufacturers, this means a rapid ROI—often within 12–18 months—driven by labor savings and reduced scrap.

Core Technologies: The Anatomy of a Smart Tray Loader

The system’s power lies in its integrated technologies, solving real-world challenges with precision and adaptability:

1. Vision-Guided Navigation: Seeing Beyond the Obvious

A high-resolution AI vision system acts as the robot’s “eyes,” enabling it to:

- Identify Parts in Chaos: Locate components in jumbled feeders (e.g., vibratory bowls or conveyor belts) and compensate for positional/orientation errors up to 1mm.

- Inspect on the Fly: Detect defects like bent pins, scratches, or misprints with 99.9% accuracy before loading, preventing faulty parts from entering the supply chain.

Example: In a PCB factory, the system distinguishes between 0402 and 0603 resistors in a mixed tray and places each into its correct slot—no manual sorting required.

2. Modular End-of-Arm Tooling: One Robot, Endless Possibilities

Quick-release grippers and suction cups allow the system to handle 100+ part types without downtime:

- Soft Grippers: Gently grasp fragile items like glass substrates or medical vials (applying <1N of force).

- Magnetic/Electrostatic Tools: Securely hold metal components or plastic parts without marking surfaces.

- Tool Change Time: <5 minutes, enabling rapid switching between tray sizes (from 50mm×50mm micro-trays to 1200mm×1000mm industrial pallets).

3. Force-Torque Sensing: Delicate Control for Critical Tasks

A 6-axis force sensor ensures safe, precise placement, especially for sensitive applications:

- Collision Detection: Stops motion instantly if resistance exceeds a preset threshold (e.g., 3N for a microchip), avoiding damage.

- Depth Control: Places parts at the exact tray depth, critical for stacked components in automotive or aerospace trays.

Transforming Industries: Real-World Applications

1. Electronics: Micro-Precision for Miniature Components

In the production of TWS earbuds, where 15+ tiny parts (each <5mm) must be loaded into anti-static trays:

- The system picks 0.8mm-thick speaker diaphragms from a chaotic feeder using vision-guided precision.

- Places them into 80-slot trays with 0.03mm accuracy, reducing loading time by 70% and defects by 90%.

Result: A leading audio brand scales production from 500 to 1,500 units/hour with zero misaligned parts.

2. Pharmaceuticals: Hygienic and Error-Free Loading

For sterile environments (e.g., loading insulin pens or diagnostic cartridges):

- Stainless Steel & FDA-Compliant Design: Meets strict hygiene standards, preventing contamination.

- Vacuum Suction Grippers: Securely handle glass vials or plastic syringes without deforming them.

Case Study: A biotech firm uses the system to load 2,000 COVID-19 test kits per hour into sterile trays, with 100% orientation accuracy and zero part damage.

3. Automotive: Heavy-Duty Efficiency for Complex Components

In engine part production, where trays hold 20+ metal components (e.g., gears, bearings, or cylinder heads):

- Robust Grippers: Handle weights up to 10kg, with vision mapping to avoid collisions in multi-layer trays.

- Multi-Part Sorting: Separates left/right components (e.g., brake calipers) using AI-driven shape recognition.

Outcome: A Tier 1 automotive supplier cuts loading time by 60%, enabling 24/7 operation with <0.5% downtime.

4-Axis vs. the Competition: A Performance Showdown

| Metric | 4-Axis Robotic System | Manual Labor | 6-Axis Robot | Conventional Gantry |

| Speed (parts/min) | 150–200 | 20–30 | 80–100 | 50–70 |

| Positioning Accuracy | ±0.02mm | ±0.5mm (variable) | ±0.05mm | ±0.1mm |

| Changeover Time | <10 minutes | 60+ minutes | 30 minutes | 45+ minutes |

| Flexibility | Adapts to 100+ part types | Low (operator skill) | Medium | Low (fixed programming) |

| Cost (USD) | $50k–$120k | Labor-intensive | $150k–$250k | $100k–$180k |

The Business Case: Beyond Automation to Innovation

1. Rapid ROI and Scalability

- Labor Savings: Replaces 2–3 operators per workstation, saving $40k–$60k annually in regions with moderate labor costs.

- Quality Improvements: Reduces scrap rates from 10% to <1%, a critical gain for high-value components like semiconductors.

- Future-Proofing: Modular design and software-driven recipes enable quick deployment for new products—no hardware overhauls needed.

2. Smart Factory Integration

- IoT Connectivity: Feeds real-time data (cycle times, error rates, tool status) to MES systems for predictive maintenance and production optimization.

- AI Path Planning: Machine learning algorithms continuously refine pick-and-place routes, shaving 5–10% off cycle times over time.

The Future of Tray Loading: Where Precision Meets Speed

As Industry 4.0 accelerates, the 4-Axis Robotic Tray Loading System evolves to meet emerging needs:

- Collaborative Workcells: Works safely alongside humans in shared spaces, using 3D vision to avoid collisions.

- Edge Computing: Processes vision data locally for sub-millisecond decision-making, critical for ultra-high-speed lines.

- Sustainability: Reduces energy use by 30% compared to older automation systems, aligning with global green manufacturing goals.

In an era where efficiency and precision are non-negotiable, the 4-Axis Robotic Tray Loading System is more than a machine—it’s a strategic asset. It turns the mundane task of tray loading into a competitive advantage, empowering manufacturers to scale, adapt, and thrive in a rapidly evolving market.

#4Axis Tray Loading System #SCARA Robot Tray Handling #Automated Material Handling Solutions