On December 29th, SYNDA, as a pioneer in the industry, officially unveiled SYNDA R1, the industry’s first embodied intelligent robot purpose-built for industrial scenarios.

Its launch represents more than just the debut of a single product; it marks a strategic leap for SYNDA — evolving from a key player in industrial robotics and motion control to a pivotal enabler of the embodied intelligence industry. Starting with this milestone, SYNDA has taken the lead in kicking off the large-scale deployment and industrial integration of embodied intelligence, setting an industrial-grade benchmark for the industrialization of embodied robots, and injecting definitive impetus into the in-depth evolution of the manufacturing sector for a promising future.

Outstanding Core Strengths: The Exclusive Industrial-Grade “Genes” of SYNDA R1

Currently, the humanoid robot industry is universally confronted with three core pain points: most products lack dedicated design for industrial scenarios, resulting in insufficient environmental durability and continuous operation capability; sluggish system response and inadequate precision fail to meet the stringent requirements of industrial production; and the absence of unified industrial adaptation standards has hindered large-scale commercialization.

Against this backdrop, SYNDA has pioneered and defined the industrial-grade standard as the core threshold for the industrialization of embodied intelligence, and SYNDA R1 is the concrete embodiment of this criterion:

Independently developed integrated multi-layer heterogeneous intelligent control system: Equipped with a perception-planning-motion control integrated multi-layer heterogeneous controller, it delivers faster response speed and superior system stability compared with traditional loosely coupled solutions, providing core technical support for industrial-grade operations.

Industrial-grade operational capability: Configurable with dexterous hands or grippers, it supports typical industrial tasks such as assembly, grasping and material handling, and is capable of millimeter-level precision operation, perfectly matching the high-precision demands of industrial production.

Self battery-swapping for 7×24-hour continuous operation: Leveraging dual-battery hot-swappable self battery-swapping and automatic recharging technologies, it breaks the endurance limitation to achieve all-weather uninterrupted operation, aligning seamlessly with the continuous workflow of industrial production.

Adaptive to complex industrial environments with safe human-robot collaboration: Featuring a four-compartment wheeled chassis, 3D lidar and omnidirectional flexible obstacle avoidance, it ensures stable and safe movement as well as all-round protection in complex industrial settings, guaranteeing the safety of human-robot collaborative work.

Wide coverage of flexible operational scenarios: The dual-arm load is available in 3/5/10KG options, with a shoulder rotation angle ranging from -180° to 180°, a waist lifting range of 0~61cm, an operational height of 0~210cm and an operational diameter of 195cm, flexibly adapting to multi-dimensional industrial operational needs.

Full-stack independently developed high-performance, high-torque and lightweight joint modules: Realizing nanosecond-level bus synchronization, one-click self-tuning and full-frequency vibration suppression for enhanced robotic stability. The highly integrated single-board drive, partially integrated harmonic reducers and ultra-thin component design have achieved an overall weight reduction of 5kg; multi-pole and multi-slot frameless motors have increased torque density by 20%, ensuring durability for long-term continuous operation in industrial scenarios.

At present, based on industrial-grade standards, SYNDA has built a comprehensive portfolio of four embodied product lines, including collaborative robots, mobile composite robots, wheeled humanoid robots and bipedal humanoid robots. Going forward, through a platform-based and modular product family, SYNDA will provide customers with tiered solutions covering diverse scenarios and complexity requirements, laying a systematic foundation for large-scale expansion.

From Lab to Factory Floor: The Pragmatic Commercialization Journey of SYNDA R1

Large-scale application in real-world scenarios is the ultimate touchstone for industrial robots. Faced with two major industry challenges: a data desert and a scenario gap, SYNDA has leveraged the profound ecological synergy brought by Haier’s strategic equity investment, taking 163 Haier-owned factories covering the entire industrial chain as a “natural testbed”. From the very beginning of R&D, SYNDA R1 has been designed to tackle real industrial challenges such as noise, vibration and multi-task interference. This model of “born in factories, built for factories” ensures that its data accumulation, algorithm iteration and engineering optimization are always aligned with industrial demands, effectively guaranteeing a high degree of matching between product performance and industrial needs.

Beyond the challenges of scenario-based deployment, the industry is also tested by mass production capacity. SYNDA owns a demonstration smart manufacturing plant certified by the Ministry of Industry and Information Technology of China. With mature supply chain management, digital production processes and a stringent quality consistency control system, SYNDA has achieved an annual production capacity of up to 10,000 industrial robots, providing a solid underpinning for mass production.

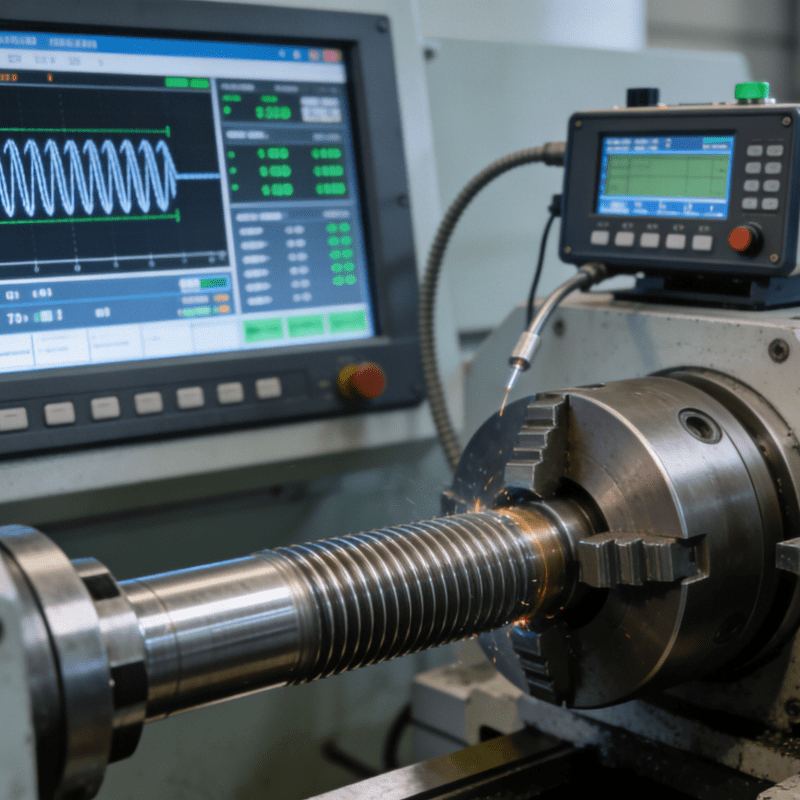

Today, SYNDA R1 has made solid strides in industrialization exploration: in real-world scenarios such as Chongqing factories, it has initially implemented the commercialization of typical tasks including adaptive grasping, warehousing and logistics handling, flexible PCB board quality inspection, dual-arm collaborative assembly, and seamless integration with Automatyczny system załadunku/rozładunku tokarki CNC to realize automated material transfer between storage areas and CNC lathes, greatly improving the continuity and efficiency of precision machining production lines.

Ecological Synergy: Accelerating the Industrialization of Embodied Intelligent Robots

The intelligent upgrading of manufacturing is not a solo effort by a single enterprise, but a systematic project that requires the synergy of software, hardware and platforms, as well as linkage across the industrial chain. SYNDA’s core ecological competitiveness stems from the dual-wheel drive of its 30 years of industrial heritage and strategic ecological synergy:

From the perspective of industrial roots, adhering to the philosophy of “Rooted in Industry, Understanding Industry Deeply”, SYNDA has solidified its development foundation with 30 years of accumulation in the industrial automation sector. As one of the few industry players that entered the market from motion control technology and extended from controllers to robot ontology manufacturing, SYNDA has built a full industrial chain layout covering core components, robot ontology and system integration. It has also constructed differentiated competitive barriers with core technologies of integrated drive and control as well as multi-core heterogeneity, and its SCARA robots have firmly established themselves in the first tier of domestic brands.

In terms of strategic synergy, following Haier’s strategic equity investment in 2025, SYNDA has officially become a new member of the Haier ecosystem. The two parties have formed in-depth synergy based on their respective strengths: SYNDA’s advanced hardware R&D and manufacturing capabilities in industrial automation are deeply integrated with COSMOPlat’s industrial internet platform infrastructure, IT-layer software capabilities and solutions, building a complete closed loop of software-hardware-platform, and providing strong support for the scenario-based deployment and ecological expansion of embodied robots.

On this basis, SYNDA has built an open cooperation ecosystem, partnering with Alibaba Cloud, NVIDIA, ByteDance and other leading enterprises in cloud computing, AI computing power and development frameworks. This open strategy enables SYNDA to integrate top global resources, build a complementary and collaborative innovation industrial ecosystem, accelerate the iteration of embodied intelligence technologies and the expansion of application scenarios, and fuel the accelerated industrialization of industrial humanoid robots.

The launch of SYNDA R1 is more than a product success; it is the prelude to a new era — an era where embodied intelligence truly steps into the core links of industrial production.

Building on this milestone, SYNDA’s future development path is clear: laying a solid foundation of reliability with industrial-grade standards, driving continuous evolution with real scenario data, and gathering leapfrog momentum with an open industrial ecosystem. Teaming up with industrial partners, SYNDA is committed to jointly propelling the profound transformation of China’s manufacturing industry, and engraving a distinct mark of Chinese innovation on the new blueprint of global smart manufacturing.