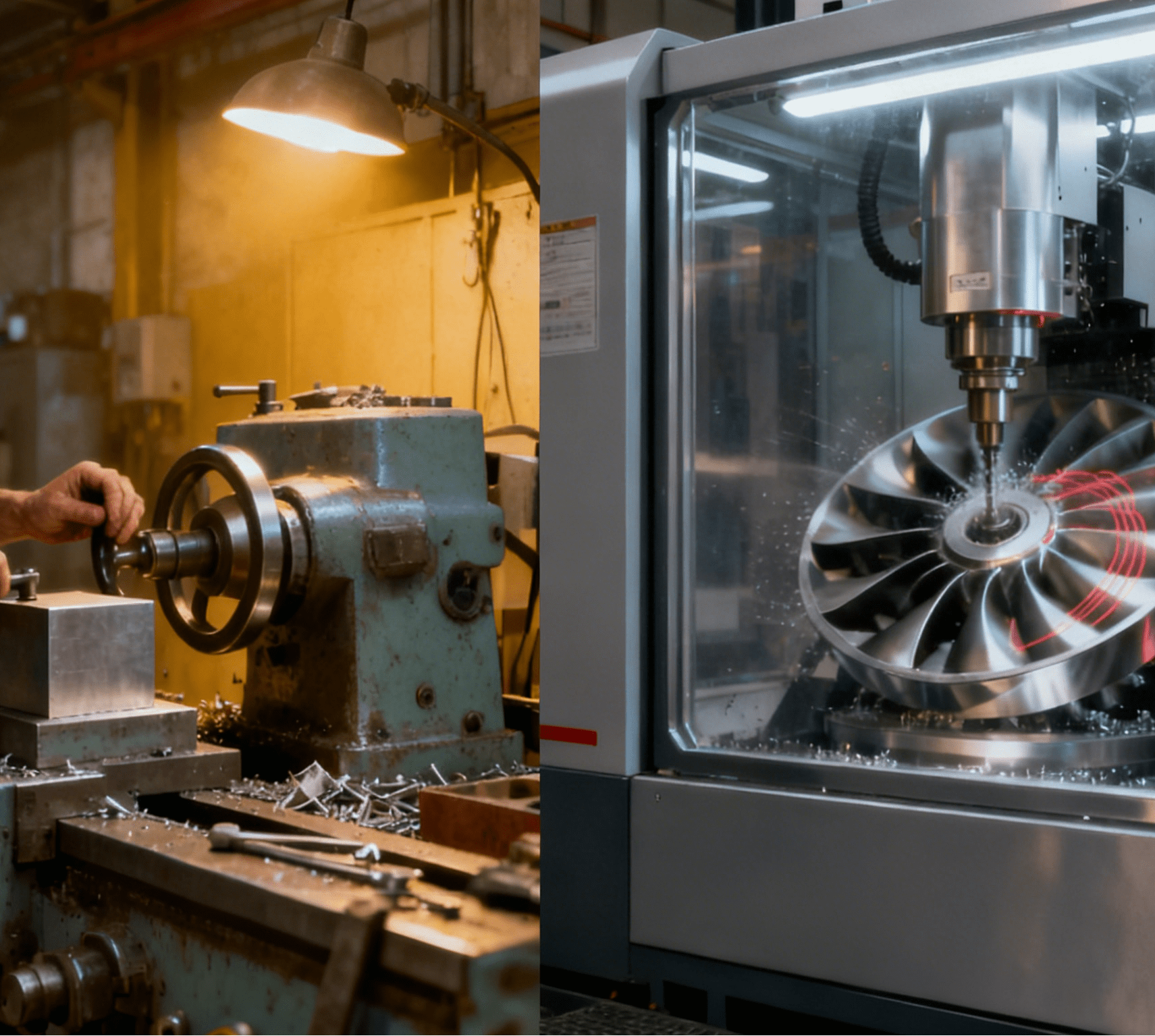

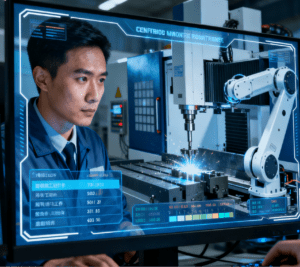

In modern manufacturing, precision CNC machining centers are highly favored for their high efficiency and high-precision machining capabilities. Today, the functions of machining centers on the market are constantly enriched, ranging from simple milling and drilling to complex multi-axis linkage machining, automatic tool changing, and on-machine inspection. So, is more function integration really better?

Notable Advantages of Function Integration

From a positive perspective, function integration indeed brings many significant advantages. Firstly, multi-function integration greatly improves machining efficiency. For example, the automatic tool changing system enables the machining center to complete multiple different processes in a single clamping, eliminating the need for frequent tool changes and workpiece re-clamping, which significantly reduces auxiliary machining time. For the manufacturing of complex parts, such as aero-engine blades that require multiple processes including milling, drilling, and boring, machining centers with multiple functions can complete the machining task in one go, effectively shortening the machining cycle and improving production efficiency. Another typical example is the integration of Automatic Sealing Ring Feeding and Assembly function into precision CNC machining centers: for precision components that require sealing ring assembly after machining (such as hydraulic valve cores), the integrated equipment can complete machining, cleaning, and automatic sealing ring feeding and assembly in a single clamping, avoiding position deviation caused by manual transfer and re-clamping, while reducing the auxiliary time between processes by more than 30%.

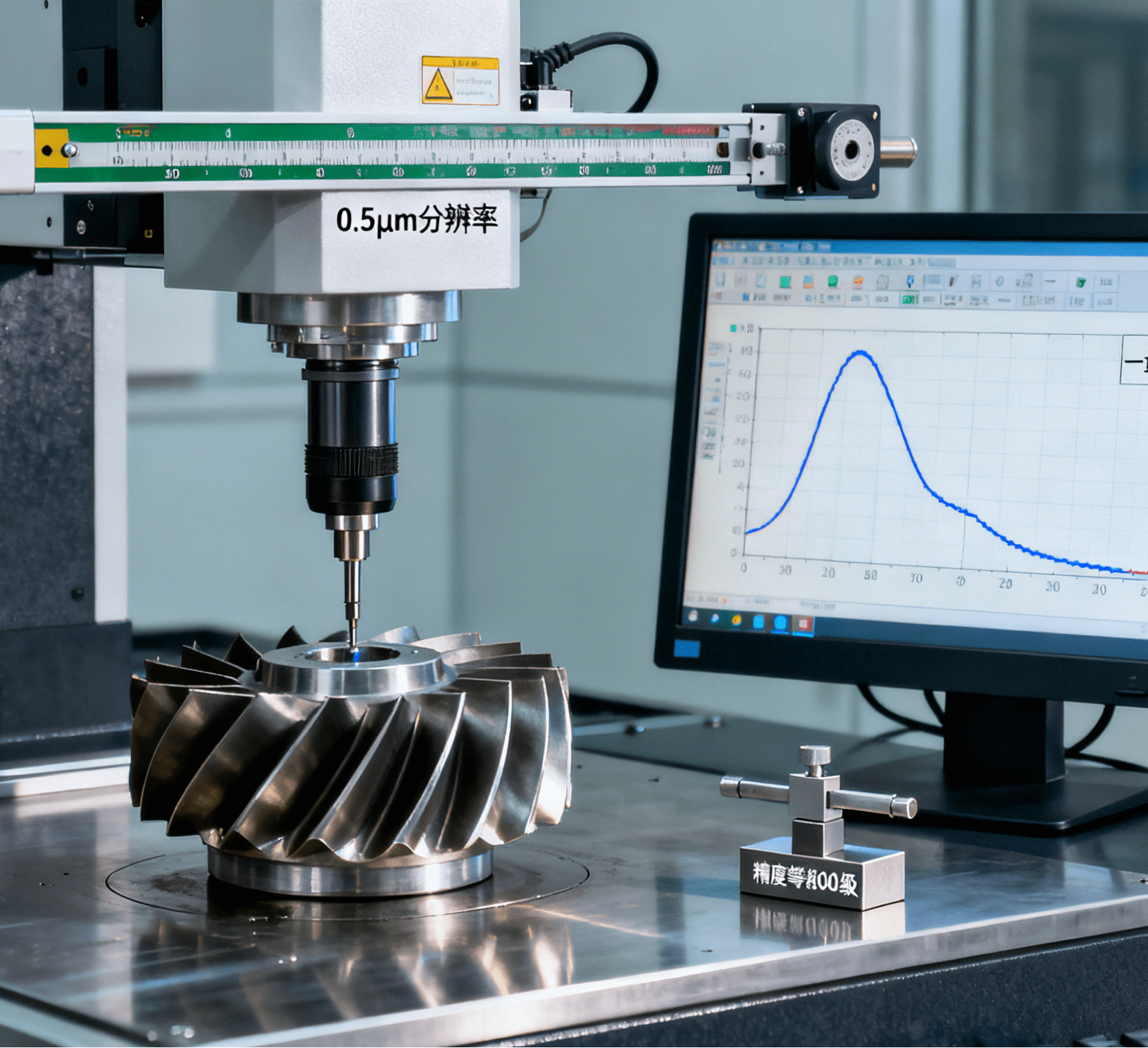

Secondly, function integration helps improve machining precision. The multi-axis linkage function can realize more complex curved surface machining, making the shape of the machined part closer to the design requirements and reducing the cumulative error caused by multiple clamping and process conversion. The on-machine inspection function can real-time monitor the dimensional and shape accuracy of the workpiece during machining. Once a deviation is detected, the machining parameters can be adjusted in a timely manner to ensure the stability and reliability of machining precision. This is particularly important in fields with extremely high precision requirements such as precision mold manufacturing, which can effectively improve product quality and qualification rate.

Furthermore, machining centers with integrated functions have stronger adaptability and flexibility. They can flexibly configure various functional modules and quickly switch machining modes according to different machining tasks and part requirements, meeting diverse production needs. Whether it is single-piece small-batch production or large-scale production, they can exert good machining performance, reduce the enterprise’s equipment purchase cost and production management cost, and improve the enterprise’s market competitiveness.

Potential Drawbacks of Excessive Function Integration

However, function integration is not without drawbacks. On one hand, the richer the functions, the more complex the structure of the machining center, and the R&D, design, manufacturing, and maintenance costs of the equipment will also increase significantly. A complex structure may lead to reduced equipment reliability and more fault points. Once a fault occurs, the maintenance difficulty and cost will increase accordingly. For example, some highly integrated machining centers have complex electrical control systems and mechanical transmission systems, which require professional technicians and a long time for fault diagnosis and repair. This may lead to production interruptions and bring economic losses to enterprises.

On the other hand, for some specific machining tasks or enterprises, excessive functions may be redundant. If an enterprise mainly engages in the mass production of simple parts, some advanced multi-axis linkage and complex functions may be rarely used, but the existence of these functions increases the equipment purchase cost and operating cost. Moreover, excessive function integration may complicate operations and raise higher requirements for the technical level and training of operators. If operators cannot proficiently master the operation and programming of various functions, it may instead affect machining efficiency and quality.

Rational Choice for Function Integration: Demand Adaptation as the Core

In summary, more function integration is not always better for precision CNC machining centers. Instead, it is necessary to comprehensively consider various factors such as the enterprise’s actual machining needs, production scale, budget, and the technical level of operators. When selecting a machining center, enterprises should adhere to the core principle of “adapting to needs”, avoid blindly pursuing function stacking, and achieve the optimal matching between equipment value and production needs.