New technological achievements empower industrial production automation: Intelligent upgrading leads the new future of manufacturing

Driven by the wave of the Fourth Industrial Revolution, the global manufacturing industry is undergoing a profound transformation from mechanization to intelligence and networking. Recently, Chinese technology enterprises in multiple fields have successively released breakthrough achievements in the field of industrial automation, covering core areas such as intelligent robots, industrial Internet platforms, and digital twin technologies, marking that China’s industrial production automation process has entered a new stage of “all-factor collaboration”.

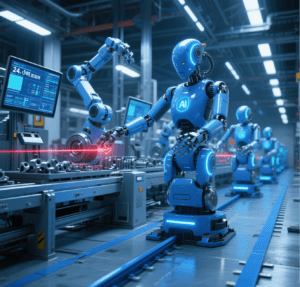

Robot cluster operations break through efficiency limits

In an automobile parts factory in the Yangtze River Delta, the latest generation of collaborative robot clusters has realized 24-hour unmanned production. Different from traditional industrial robots, these devices equipped with AI vision systems can independently identify workpiece models, adjust processing parameters, and dynamically optimize the production line layout through swarm intelligence algorithms. According to test data, the system has increased the production line switching efficiency by 40% and reduced unit energy consumption by 18%. The person in charge of the R&D party revealed that the core breakthrough lies in the development of a multi-machine scheduling model based on reinforcement learning, enabling robots to have “human-like” on-site decision-making capabilities.

Industrial Internet builds a digital nerve center

The “Industrial Internet Innovation and Development Action Plan” recently released by the Ministry of Industry and Information Technology shows that China has built the world’s largest industrial Internet identification resolution system. In a “lighthouse factory” built by a home appliance giant in the Guangdong-Hong Kong-Macau Greater Bay Area, the 5G+MEC edge computing architecture supports real-time data collection and analysis throughout the entire process. From raw material storage to finished product delivery, each link is embedded with intelligent sensors. The virtual factory built through digital twin technology can predict equipment failures 72 hours in advance, reducing unplanned downtime by 65%. This closed-loop control system of “perception-analysis-decision-execution” is reshaping the operation mode of traditional manufacturing enterprises.

Flexible manufacturing systems solve the problem of customization

Facing the surge in personalized demand in the consumer market, a modular intelligent production line developed by a technology enterprise provides an innovative solution. The system consists of quickly reconfigurable intelligent workstations, each unit integrating 3D vision, force control sensors, and adaptive fixtures, which can complete production line conversion within 15 minutes. In a pilot project in a clothing factory in Hangzhou, this system successfully realized the automated production of small-batch orders, compressing the delivery cycle of customized clothing from 15 days to 72 hours. Experts pointed out that this technological breakthrough of “reconfigurable hardware and software” marks that China’s flexible manufacturing capacity has reached the international advanced level.

Human-machine collaboration opens a new paradigm of safety

Safety has always been a core concern of industrial automation. The newly developed force feedback exoskeleton device realizes human-machine force collaboration through myoelectric signal recognition technology, enabling operators to safely carry heavy objects exceeding 3 times their own load. In the application test of a chemical enterprise in Shandong, the equipment not only increased the material handling efficiency by 3 times but also reduced the work-related accident rate to zero. At the same time, the intelligent safety system based on UWB ultra-wideband positioning can identify the dangerous distance between personnel and equipment within 0.1 seconds, building a digital protection network for high-risk operating environments.

According to the prediction of the China Electronics Standardization Institute, China’s industrial automation market scale will exceed 500 billion yuan by 2025, of which intelligent equipment is expected to account for more than 60%. With the deep integration of 5G, artificial intelligence, digital twin and other technologies, industrial production is transitioning from “local automation” to “global intelligence”. This transformation driven by new technological achievements is not only reshaping the competitiveness of Chinese manufacturing but also providing a “Chinese solution” for the global industrial transformation and upgrading. Driven by both policy guidance and market demand, a new industrial production ecosystem that is more efficient, more flexible, and safer is accelerating its formation.

which type of automated assembly machine is commonly used for less complex parts