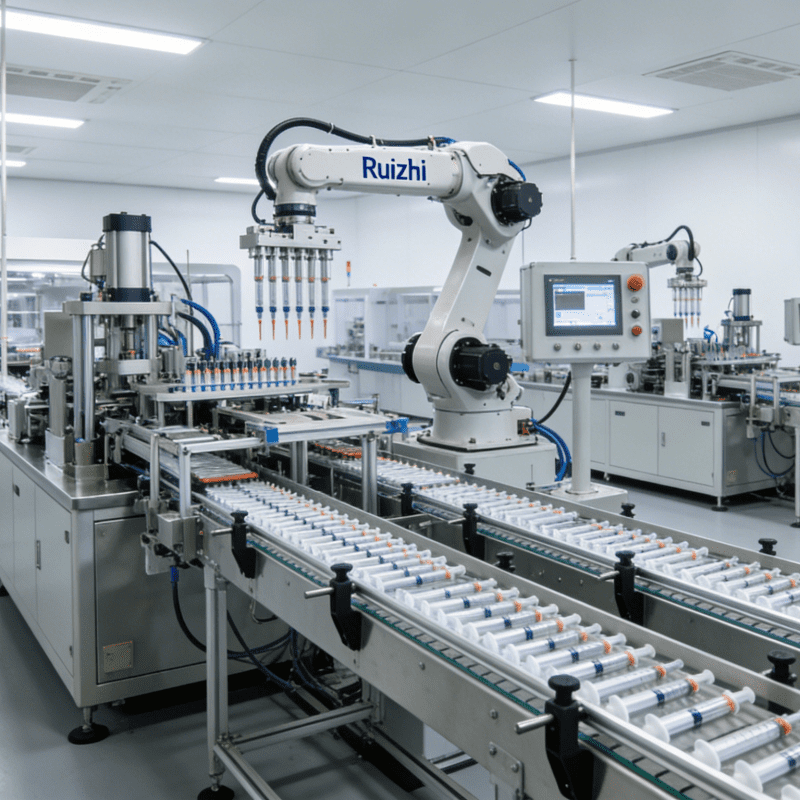

As a core equipment in medical respiratory device production, high-precision nebulizer assembly machines directly determine product quality, production efficiency and market competitiveness. For medical device manufacturers, choosing a suitable high-precision nebulizer assembly machine is crucial, especially in the context of diverse product specifications and strict medical standards. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, summarizes three key criteria to help you select the most suitable equipment and avoid procurement pitfalls.

Prioritize Precision and Compliance with Medical Standards

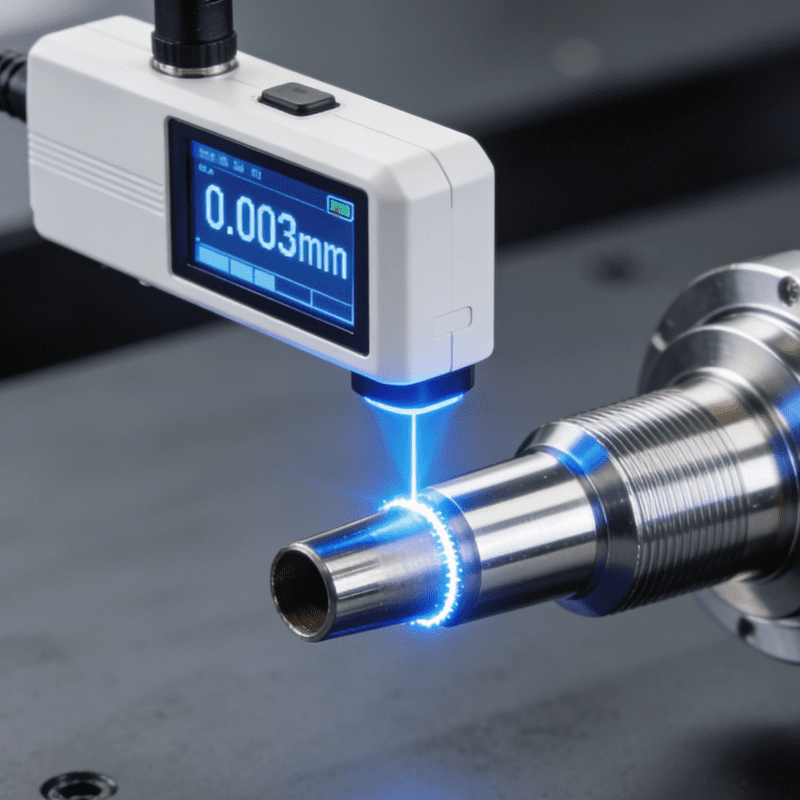

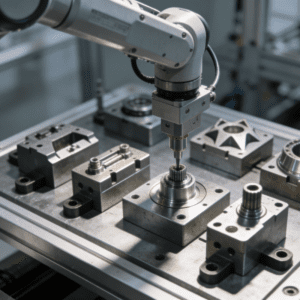

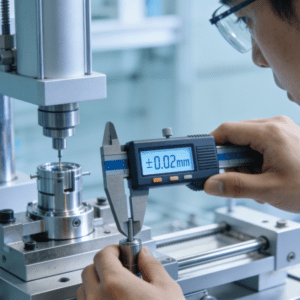

The primary requirement for nebulizer assembly machines is high precision, as nebulizers require strict air tightness, nozzle alignment and component fitting to ensure stable atomization performance. When selecting equipment, focus on its positioning accuracy (preferably within ±0.02mm) and whether it is equipped with intelligent vision inspection and real-time monitoring systems. Meanwhile, the equipment must comply with global medical standards such as ISO 13485, CE and FDA. Ruizhi’s high-precision nebulizer assembly machines adopt servo control and precision positioning technology, fully meeting medical-grade production requirements and ensuring consistent product quality.

Focus on Customization Capability for Diverse Needs

Nebulizers have various types (mesh, jet, portable, etc.) and specifications, so standard equipment often fails to meet personalized production needs. A high-quality assembly machine should have strong non-standard customization capabilities. Pay attention to whether the manufacturer can provide flexible solutions according to your product size, assembly process and production capacity. Ruizhi Intelligent Manufacturing specializes in non-standard customization, designing modular stations and adaptable tooling to match different nebulizer models, helping you reduce production costs and improve adaptability to product upgrades.

Evaluate Efficiency, Stability and After-Sales Service

Production efficiency and equipment stability are key to reducing costs and increasing profits. Choose equipment with fully automated processes (feeding, assembly, inspection, sorting) to replace manual operations and improve output. At the same time, prioritize equipment with a robust structure, low failure rate and easy maintenance. In addition, perfect after-sales service (installation, commissioning, technical training, spare parts supply) is essential. Ruizhi provides one-stop after-sales support, ensuring long-term stable operation of equipment and solving your worries in the production process.

Choosing a high-precision nebulizer assembly machine requires balancing precision, customization and efficiency. Ruizhi Intelligent Manufacturing integrates professional R&D strength and rich industry experience, providing customized high-precision nebulizer assembly solutions to help medical device manufacturers achieve intelligent and efficient production.

Assembly line for mass production by artificial intelligence