In the cosmetic and daily chemical industry, lotion pump assembly requires strict precision and hygiene standards, while facing pain points like low manual efficiency, high defect rates, and difficulty adapting to multi-spec customization. Ruizhi Intelligent Manufacturing’s cosmetic lotion pump assembly machine integrates automation, flexibility, and compliance, providing professional non-standard solutions for global cosmetic manufacturers.

Boost Efficiency & Quality

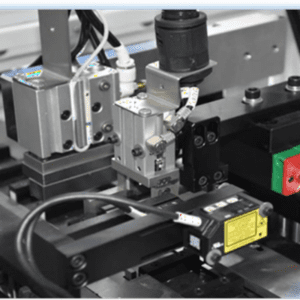

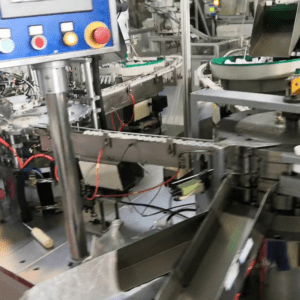

Equipped with PLC control systems and high-precision servo motors, our machine realizes fully automated assembly of 5-7 piece lotion pump components, including pump shells, springs, and pistons. Adopting circular slide rail conveying and secondary positioning technology, it achieves an assembly accuracy of ±0.1mm, with a stable capacity of 1200 pieces per hour (3 seconds per piece) . Built-in real-time detection modules automatically identify missing parts, misalignment, and air leakage, boosting the qualification rate to over 99.9% . The anti-scratch clamping design protects the pump surface, while automatic silicone oil coating optimizes dispensing smoothness, meeting cosmetic packaging’s high appearance requirements.

Adapt to Diverse Demands

Ruizhi excels in non-standard customization to match various cosmetic lotion pump types. Our machine widely adapts to common neck diameters (20mm, 24mm, 28mm, 32mm) , supporting standard round pumps, foam pumps, and anti-leakage lock pumps. Modular quick-change fixtures enable mold switching within 10 minutes without professional tools, easily handling small-batch, multi-SKU production. For high-end demands, we offer customized functions like airtightness testing and anti-splash design , fully matching the production needs of skincare, hand sanitizer, and medical cosmetic products.

Ensure Reliable Production

Constructed with 304 stainless steel and food-grade seals, the machine complies with FDA and GMP standards , avoiding material contamination and facilitating daily cleaning. Core components from renowned brands (Mitsubishi, SMC) ensure a trouble-free operation rate of over 98% and a service life of more than 5 years. It seamlessly integrates with upstream injection molding and downstream filling lines, forming a complete production chain. Ruizhi provides one-stop services including pre-delivery debugging and on-site training, safeguarding continuous production for customers.

Ruizhi’s machine reduces labor costs by over 80% while enhancing product consistency. It has become a trusted choice for cosmetic manufacturers pursuing efficient, compliant, and customized production.

How to choose a multi-component capping assembly machine suitable for your production line?