Advantages of Industrial Robot Assembly in Small Home Appliance Manufacturing

In small home appliance manufacturing, industrial robot assembly offers significant advantages: it can complete complex assembly processes with high precision, ensuring product consistency to meet stringent quality standards. Meanwhile, through coordinated automated logistics and real-time monitoring systems, it optimizes material flow, reduces the risk of downtime, and makes production lines more flexible and stable—perfectly adapting to the production needs of small home appliances, which feature multiple product categories and rapid iterations.

Austar Group: A Global Partner in Home Appliance Manufacturing

Austar Group is a partner of many well-known brands in the global home appliance industry, mainly engaged in the production of various coffee machines and related parts, with 5 factories in Switzerland, China, and other regions.

Austar’s Coffee Grinder Production Line: A Model of Automation Upgrading

Amid the global manufacturing challenges of skilled worker shortages and pressure to improve production efficiency, the transformation of Austar’s coffee grinder production line stands as a model of automation upgrading. To meet the extremely high quality and design requirements of its world-renowned brand clients, Austar Group introduced FANUC robots, achieving 100% fully automated assembly and a qualitative leap in production efficiency.

Manual Assembly Challenges at Austar’s Romanshorn Factory

The factory in Romanshorn serves as Austar’s core base for manufacturing coffee grinders. In the past, the assembly of coffee grinders here relied on 10-12 workers for manual operations, which not only faced the trouble of skilled worker shortages but also struggled to maximize production efficiency and stability.

In this automation upgrade of the coffee grinder production line, 14 FANUC LR Mate 200iD/7L robots were deployed for precision assembly, while M-20iD/25 robots handled unloading and module transfer. Among them, the Robotic Irregular – Shaped Metal Part Removal System, specially designed for metal components of coffee grinders, uses 3D visual recognition and adaptive gripper technology to accurately handle key irregularly shaped metal parts such as blades and bearings inside the grinders. This completely solves the problems of easy scratching and large positioning deviations caused by manual handling. FANUC robots, with their excellent performance in precision, speed, and flexibility, have enabled full automation of the entire assembly process.

Remarkable Changes from Innovative Configuration: Reduced Labor and Boosted Efficiency

The changes brought by this innovative configuration are remarkable. The number of assembly workers required has been drastically reduced from 10-12 to just 1 operator, who can complete the entire assembly process. At the same time, production efficiency and capacity have been significantly improved.

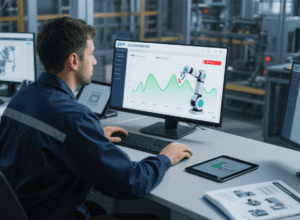

FANUC’s ZDT System: Minimizing Downtime and Maximizing Equipment Value

Furthermore, to minimize unplanned downtime and maximize equipment availability, the production line has also introduced FANUC’s cloud-based remote service system ZDT. By real-time monitoring of equipment status, this system minimizes downtime, maximizes production efficiency, extends equipment lifespan, and enables the equipment to generate higher capacity returns throughout its lifecycle, achieving an optimal balance between input and output.

Additional Benefits of Automation: Optimized Production and Logistics via Vision Systems

Notably, the automation transformation has also brought a series of additional benefits. By having the vision system directly provide coordinate information to the robots, the production line has eliminated the need for blister packaging for material distribution, further optimizing production and logistics processes.

Austar’s production director commented: “FANUC robots perform exceptionally well in terms of precision, speed, and flexibility, and they operate stably at all times. We are very satisfied with them.”