Table of Contents

ToggleAudi gears up for next-gen factory automation with smart manufacturing

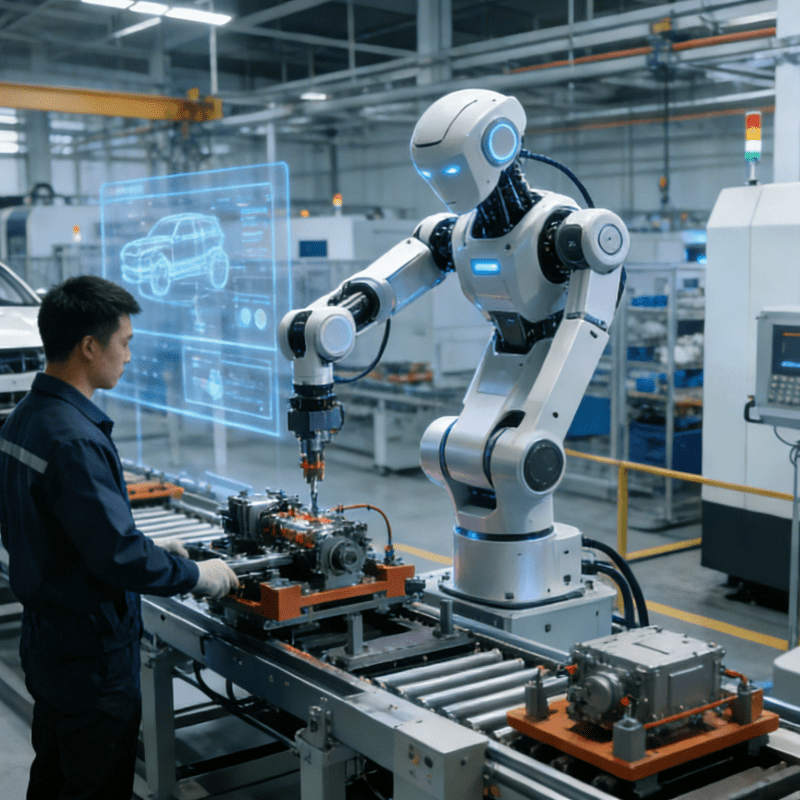

In the high-stakes arena of global automotive manufacturing, where innovation is the currency of success and efficiency is the key to survival, Audi is making waves with its latest technological leap. Just as the automotive industry is evolving rapidly, the sectors involved in manufacturing Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment also face the imperative of innovation and efficiency to stay competitive. As the automotive industry hurtles towards a future defined by electrification, digitalization, and sustainability, the German luxury carmaker is leaving no stone unturned in its quest to stay ahead of the curve. With the launch of its Edge Cloud 4 Production (EC4P) initiative, Audi is revolutionizing the way factories operate, leveraging cutting-edge virtual technology to create a manufacturing ecosystem that is smarter, more agile, and more sustainable than ever before. This bold move not only signals Audi’s commitment to technological leadership but also sets a new standard for the entire automotive industry, demonstrating how smart manufacturing can transform the production process from end to end. The same principles of smart manufacturing and technological innovation could have a profound impact on the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, potentially streamlining their manufacturing processes and enhancing product quality.

Global auto manufacturer Audi deploys virtual private cloud environment platform to deliver enhanced automation, reconfiguring production line to accommodate a product mix change and scale compute and storage

In the modern auto manufacturing industry, reducing cost, complexity and environmental impact is paramount. Similarly, in the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, manufacturers strive to cut costs, simplify processes, and minimize environmental footprint. As part of its strategy to keep up, Audi announced that it has gone live with its Edge Cloud 4 Production (EC4P) IT-based factory automation initiative using the first virtual programmable logic controller (vPLC) at its Böllinger Höfe plant in Germany.

The use of such a virtual technology core is intended to allow Audi to build a manufacturing future that is more efficient, cost-effective and secure. Audi has been testing the EC4P local server solution at Böllinger Höfe since July 2022, with series production tests taking place since July 2023. In the realm of manufacturing Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, similar testing phases could lead to the adoption of innovative technologies that improve production outcomes.

A local server cluster has been set up on the production site to control the worker support systems for two production cycles of the Audi e-tron GT quattro, RS e-tron G and Audi R8 models. In the future, the software-controlled, flexible and scalable server solution will replace the legacy decentralised control system that relies on high-maintenance industrial PCs. This transition towards a more software-driven and scalable system could inspire manufacturers of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment to upgrade their own production control systems, reducing maintenance costs and increasing flexibility.

In addition, EC4P will allow Audi to redeploy the computing power the production line requires to local data processing centres and is simultaneously adapting EC4P for other use cases in the Audi Production Lab (P-Lab). The concept of repurposing computing resources and exploring new use cases can be applied to the manufacturing of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, where finding ways to optimize resource usage and expand the capabilities of production systems is crucial.

EC4P is powered by VMware Cloud Foundation (VCF) software, which Audi is using to deliver smart manufacturing by bringing software-defined factory automation to the shop floor and bridging the gap between IT and operational technology (OT), creating a private cloud outside of the Boellinger Hoefe manufacturing plant in Germany, where critical shop floor workloads are hosted and managed centrally. The integration of IT and operational technology in the automotive sector through VCF could serve as a model for the manufacturing of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, where combining digital technologies with physical production processes can lead to significant improvements.

Benefits of the EC4P initiative

With VCF, Audi aims to achieve a number of key benefits including better agility and scalability through cloud infrastructure; reduced costs through less hardware maintenance, and centralised software and operating system updates; lower environmental impact through a smaller hardware footprint that generates less heat, consumes less power and results in less e-waste; enhanced security and resilience through automated and centralised patching at scale; and use of immutable snapshots in the event of an attack or breach. These benefits are not only relevant to automotive manufacturing but also to the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment. For example, reduced hardware maintenance and lower environmental impact can be achieved by adopting similar cloud-based and software-defined automation solutions in the manufacturing of these equipment, while enhanced security can protect valuable production data and intellectual property.

Instead of maintaining physical industrial PCs for running thousands of “worker stations” across the factory, these can now be run as virtual machines (VM) on VMware Cloud Foundation outside of the actual plant. Software and operating system updates can be done as a parallel operation instead of forcing them into the short shift changeover times. If a worker station VM has issues, it can be replaced remotely. In the production lines for Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, this kind of remote management and seamless software update mechanism can prevent production disruptions, ensuring continuous and efficient manufacturing.

The VCF private cloud platform also enables Audi to centralise the management and maintenance of dedicated industrial PC devices located on the factory floor, simplify security patching and risk management, and reduce environmental impact by using less hardware and fewer manual operations. Manufacturers of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment can draw inspiration from this approach, seeking to centralize management and reduce manual operations to improve overall production efficiency and sustainability.

Perspectives from key stakeholders

“The use of virtual programmable logic controllers in the body shop is an important productivity leap in our 360 factory strategy for efficient and data-driven manufacturing,” said Audi board member for production Gerd Walker. “We want to bring the local cloud for production to all plants and leverage advances in digital control systems in the process.” This vision of widespread adoption of advanced digital control systems can be paralleled in the manufacturing of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, where a similar push towards digitalization can lead to transformative improvements in productivity.

The initiative includes close partnership between key technology partners including VMware parent Broadcom, Cisco and Siemens. Collaborative efforts like these can also drive innovation in the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, as manufacturers in this sector can seek partnerships with technology providers to develop and implement advanced manufacturing solutions.

Sven Müller, project lead for EC4P at Audi, said: “The collaboration between Audi and Broadcom is core to building a manufacturing future that is more efficient, cost-effective and secure. Through our work together, we’re setting new standards for precision, customisation and environmental sustainability. “EC4P will reduce our hardware footprint, replacing thousands of decentralised industrial PCs with a more efficient, scalable and flexible architecture of local edge servers that unites the cloud and the edge on the shop floor.” The goals of precision, customization, and environmental sustainability are equally important in the manufacturing of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, and the approach of reducing hardware footprint through innovative solutions can be emulated in this industry.

Paul Turner, vice-president of products for VMware Cloud Foundation Division at Broadcom, added: “As Audi seeks to take factory automation to the next level and benefit from a scalable infrastructure at its factories worldwide, VMware Cloud Foundation will enable the replacement of industrial PCs and specialty hardware on the shop floor with general purpose servers running consistent VMware cloud infrastructure software.” This shift towards more general-purpose and software-driven infrastructure can be a game-changer in the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, enabling more efficient and adaptable manufacturing processes.

As Audi’s Edge Cloud 4 Production initiative continues to roll out and prove its worth, the automotive giant is not just transforming its own manufacturing processes; it’s laying the groundwork for a new era of smart factories. The successful implementation of EC4P at the Böllinger Höfe plant is just the beginning. With plans to expand this innovative technology across all its manufacturing facilities, Audi is poised to redefine what it means to produce high-quality vehicles in the 21st century. Similarly, the lessons learned from this initiative can inspire manufacturers of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment to embark on their own journeys of digital transformation. The adoption of smart manufacturing technologies can lead to the creation of more sustainable, efficient, and intelligent production ecosystems in this sector as well. Audi’s journey into the future of factory automation is a testament to the endless possibilities that lie ahead when innovation meets determination, and it serves as a beacon of hope for an industry on the cusp of a major revolution, including the manufacturing of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment.