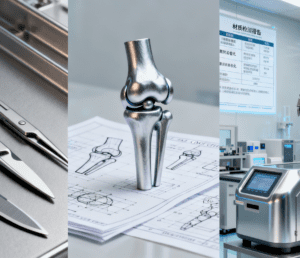

In the design and manufacturing of modern medical equipment, material selection is crucial. Aluminum alloy has become an indispensable material in the medical industry due to its excellent properties such as lightweight, high strength, and corrosion resistance. Today, we will delve into three common types of aluminum alloys—6061, 7075, and 5052—exploring their application scenarios and advantages in medical equipment.

AL6061: The All-Round Performer

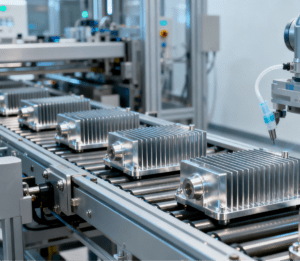

Balancing strength and corrosion resistance, AL6061 is widely used in the medical equipment industry thanks to its superior mechanical properties. More importantly, AL6061 is highly suitable for precision equipment with complex geometries that require high customization. It can undergo high-difficulty welding processes while largely maintaining its intact appearance and shape. Therefore, when manufacturing components such as pharmaceutical bottle rotating plates, surgical equipment brackets, base plates for medical testing instruments, and key parts of Maszyna do montażu wskaźników biologicznychs (such as the machine’s body frame and core assembly components), Arie (Note: Proper noun, retained as “Arie” unless an official English name exists) often regards AL6061 as the most ideal choice—its structural stability and processability ensure the assembly machine operates with high precision and long-term reliability during the delicate assembly of biological indicators.

AL7075: Synonymous with High Strength

Known as a synonym for high strength, AL7075 aluminum alloy is the preferred material for many load-bearing components and high-precision equipment. In the ECR (Electron Cyclotron Resonance) channel vertical plate project, Arie selected AL7075 as the core material and further enhanced its hardness and corrosion resistance through natural anodization treatment. This not only ensures the stable performance of the vertical plates in harsh working environments but also provides strong support for the reliable operation of the equipment.

AL5052: The Corrosion Resistance Expert

In addition to its excellent formability—making it suitable for designing medical equipment with various complex shapes—the most prominent feature of AL5052 lies in its outstanding corrosion resistance. Even in high-humidity or high-acid/alkali chemical environments, it can maintain the stability of components for a long time. Therefore, AL5052 is the best choice when designing parts such as inkjet printer casings, precision nozzles, and detector housings.

The application of aluminum alloys in the medical field not only reflects the progress of modern manufacturing technology but also carries the mission of serving healthcare. In the future, Arie Precision will leverage its keen insight, exquisite technology, and rich manufacturing experience to provide more stable-performance precision components for the medical equipment industry and deliver safer, more reliable medical experiences to patients.