In modern manufacturing, precision manufacturing has become a core driver of technological progress and product innovation. Whether in the production of aerospace, automotive, electronic equipment or medical devices, precision manufacturing technology plays an indispensable role. Behind precision manufacturing, a range of advanced equipment ensures the high-precision and high-efficiency processing of products, among which 5-axis CNC machine tools stand out as star equipment in the manufacturing industry.

For many people, 5-axis CNC machine tools may still be a somewhat mysterious term. What makes them unique, and why are they widely used in high-precision processing? This article will take you into the world of 5-axis CNC machine tools and uncover the mystery behind them.

What are 5-Axis CNC Machine Tools?

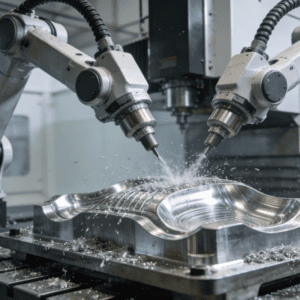

A 5-axis CNC machine tool is a high-precision machine tool capable of performing machining operations on five different axes simultaneously. Unlike traditional 3-axis CNC machine tools, 5-axis models add two rotary axes, enabling operations in two rotational directions in addition to the three linear directions (X, Y, Z).

Specifically, the five axes of a 5-axis CNC machine tool include:

X-axis: Horizontal movement in the left-right direction

Y-axis: Horizontal movement in the front-back direction

Z-axis: Vertical movement in the up-down direction

A-axis: Rotation around the X-axis

B-axis: Rotation around the Y-axis

Through the coordinated operation of these five axes, 5-axis machine tools can machine workpieces from multiple angles and directions in complex spatial environments, completing high-difficulty machining tasks that are hard to achieve with traditional 3-axis machine tools.

Core Advantages of 5-Axis CNC Machine Tools

The widespread application of 5-axis CNC machine tools in precision manufacturing stems from their following core advantages:

High-precision machining: 5-axis machine tools enable simultaneous machining control across multiple axes, avoiding error accumulation caused by frequent fixture changes in traditional machine tools, thus greatly improving machining precision. This is particularly crucial for industries with ultra-high precision requirements such as aerospace and mold manufacturing. Even workpieces with complex curved surfaces and intricate geometric shapes can be easily processed by 5-axis machine tools.

Shorter machining time: Traditional 3-axis machine tools usually require multiple clamping operations to finish complex parts, while 5-axis machine tools can complete all-directional cutting with a single fixture loading, significantly reducing workpiece machining time. This makes 5-axis CNC machine tools highly competitive in mass production, especially in industries demanding both high precision and efficiency such as auto parts and medical device manufacturing.

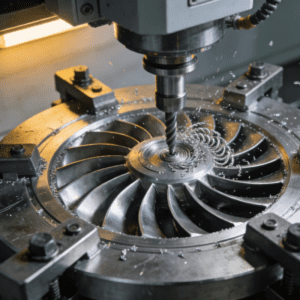

Capability to machine complex parts: For some high-difficulty machining tasks, traditional methods may be unfeasible or extremely inefficient. 5-axis machine tools can adjust multiple machining angles simultaneously, allowing them to process more complex components. For example, turbine blades of aero-engines and aircraft fuselage parts often feature highly complex geometric shapes and require ultra-precise surface quality, where the capabilities of 5-axis CNC machine tools are particularly valuable.

Improved surface quality: Since 5-axis machine tools perform machining from multiple angles, the contact angle between the cutting tool and the workpiece is always maintained at an optimal state during processing. This not only boosts machining efficiency but also significantly improves the surface finish of workpieces, reducing surface defects and unevenness.

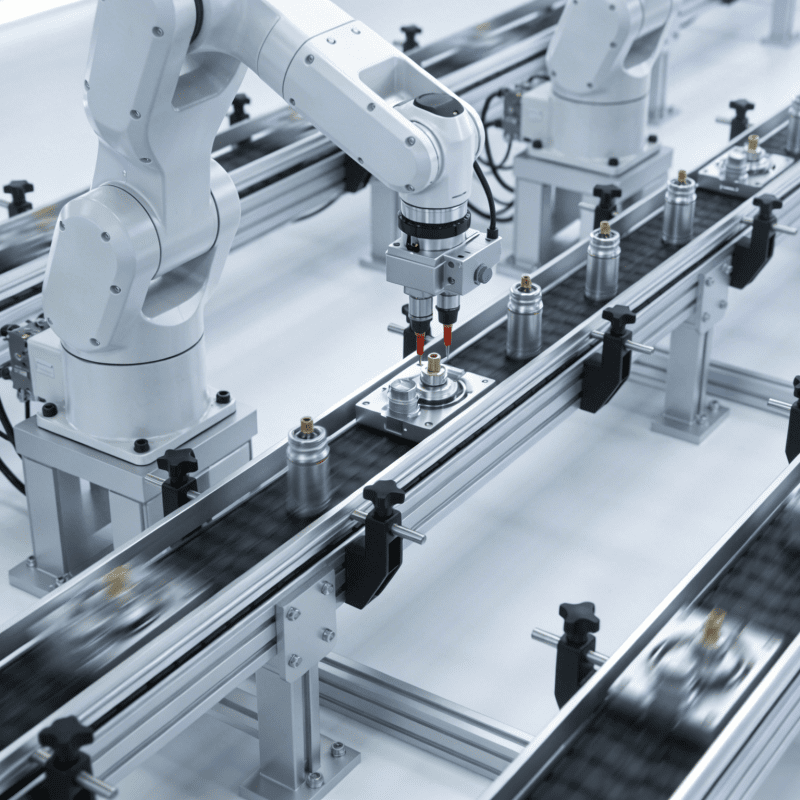

Reduced manual intervention: 5-axis CNC machine tools adopt digital control and can fully automate the machining process of complex parts, thus greatly reducing manual operation intervention and errors. Through programmed control, the machining quality and efficiency of workpieces can be better guaranteed.

Application Fields of 5-Axis CNC Machine Tools

Thanks to their outstanding performance, 5-axis CNC machine tools are widely used in various high-precision manufacturing fields. The key application areas are as follows:

Aerospace industry: The aerospace sector has extremely high requirements for the precision and complexity of components. 5-axis machine tools can accurately machine turbine blades, engine casings, aircraft fuselage structural parts and other components that typically feature complex shapes and demand high-precision surface quality – requirements that 5-axis machine tools are perfectly suited to meet.

Automotive manufacturing: 5-axis machine tools play a pivotal role in automotive manufacturing, especially in the production of key components such as engine parts, gearbox components and suspension systems. Their ability to handle complex geometric shapes and fine machining requirements makes them indispensable equipment in automotive manufacturing.

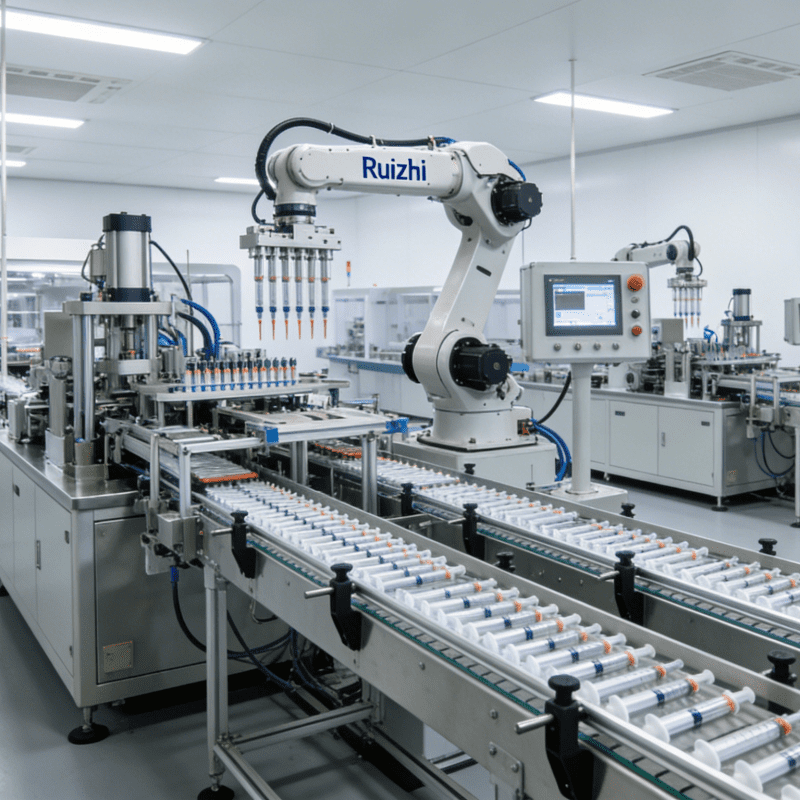

Medical device manufacturing: In the medical device industry, particularly for high-precision devices such as artificial joints and dental instruments, 5-axis CNC machine tools also play an important role. Their high-precision machining and excellent surface quality make medical devices more reliable and safe.

Mold manufacturing: The mold industry requires a large number of precision-machined mold parts, which usually have complex geometric shapes and demand high-precision fitting. 5-axis machine tools can meet the stringent precision and complexity requirements of mold manufacturing.

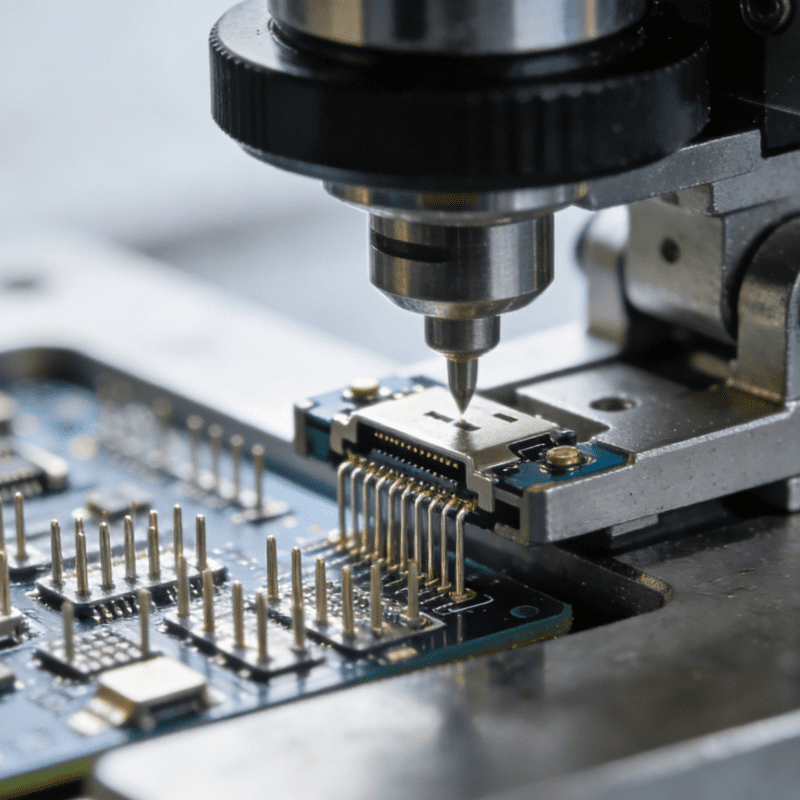

Precision electronic component processing: 5-axis machine tools are widely used in the production of electronic products, especially for precision casings and internal components of mobile phones, computers and other electronic devices. They can achieve high-precision machining of micro parts, ensuring the high performance and long service life of electronic equipment.

Challenges and Future Trends of 5-Axis CNC Machine Tools

Despite their unparalleled advantages in precision manufacturing, the application of 5-axis CNC machine tools still faces several challenges:

High equipment cost: Due to their high integration and complex functions, 5-axis CNC machine tools are usually expensive, which may become a barrier for small and medium-sized enterprises to purchase and use them.

High operational technical requirements: The operation and programming of 5-axis machine tools are highly complex, requiring operators to possess considerable technical proficiency. In programming in particular, it is necessary to accurately calculate and adjust the motion trajectory of each axis, which places higher demands on operator training.

High maintenance costs: The complex structure of 5-axis CNC machine tools leads to relatively high maintenance and upkeep requirements. The precision and stability of the equipment need regular inspection and adjustment, resulting in relatively high maintenance costs.

However, with the continuous development of technology, 5-axis CNC machine tools are constantly evolving. In the future, they will move towards greater intelligence, automation and refinement:

Intelligence and Automation

Future 5-axis CNC machine tools will be more intelligent, capable of automatically detecting and adjusting problems during machining, and even realizing self-learning and optimization to improve production efficiency and reduce manual intervention.

Higher Speed and Precision

With the advancement of high-end materials and technologies, 5-axis CNC machine tools will achieve higher machining speeds while maintaining ultra-high precision, meeting the requirements of more complex manufacturing processes.

Cloud Technology and Big Data

In the future, 5-axis machine tools are likely to integrate with cloud data platforms for real-time monitoring and data analysis, thereby further optimizing the production process and improving production quality and efficiency.

Conclusion

axis CNC machine tools, with their unparalleled precision machining capabilities, have become an important piece of equipment in modern manufacturing. They not only hold advantages in improving production efficiency and reducing machining time but also demonstrate enormous potential in the production of precision and high-complexity parts. With the continuous development of technology, 5-axis CNC machine tools will continue to play an important role in a wider range of fields, bringing more innovations and breakthroughs to the manufacturing industry.

How to choose a multi-component capping assembly machine suitable for your production line?