The bottleneck preventing humanoid robots from moving from laboratories to factories and homes is not usually “can they walk,” but “can they grasp.” As the “nerve endings” of robots, dexterous hands account for about one-fifth of the total cost and directly determine whether a robot can pick up an egg, hold a cup steadily, open a bottle cap, or even perform minimally invasive surgery. This “hand” that integrates precision machinery, flexible electronics, and AI is truly the “last centimeter” in robot industrialization.

As the humanoid robot boom intensifies, the dexterous hand industry stands at the threshold of large-scale development. But how to balance high versatility with low cost? Should function or appearance be prioritized when imitating human hands? These questions make this emerging field both exciting and complex. And Chinese players have already provided some unique answers in this competition.

The Rapid Rise of Domestic Dexterous Hands

Dexterous hands are to robots what hands are to humans — a good dexterous hand can not only perform basic operations like shaking hands and grasping objects, but also tighten tiny screws inside precision instruments and even help doctors hold sutures finer than human hair during surgery.

In this field, the global market was long dominated by foreign companies while Chinese enterprises played catch-up. Now, however, Chinese players have transformed this gap into a “price advantage.”

Foreign companies, with their earlier start, have relatively mature technology. Tesla’s Optimus robot, for example, has seen rapid iterations in its dexterous hand technology, increasing from 11 degrees of freedom in Gen1 to 22 in Gen3, with comprehensive upgrades in drive systems, transmissions, and sensing. Britain’s ShadowRobot has even reached 24 degrees of freedom.

But these “top performers” face a major challenge: their dexterous hands are not only prohibitively expensive but also have long lead times. Products from Britain’s Shadow and Germany’s SCHUNK typically cost over $100,000 and require a 6-12 month wait — making large-scale adoption impractical.

In contrast, Chinese dexterous hand companies, riding the wave of humanoid robot development and supported by complete industrial chains and huge market demand, have progressed from “catching up” to “running alongside,” and in some areas even “leading the pack.” Statistics show that as of July 2025, there are over 60 Chinese dexterous hand enterprises, capturing about half of the global market. These players have adopted different strategies, each with their own competitive advantages.

Three Types of Chinese Players

Vertical New Forces Specializing in Dexterous Hands

Companies like Yins Time Robot, Lingxin Qiaoshou, and Lingqiao Intelligent have successfully transformed foreign “luxury products” into affordable “industrial products.”

Yins Time Robot’s RH56DFX series dexterous hand uses link transmission, has 12 active degrees of freedom, positioning accuracy of 0.2mm, and weighs only 540g, finding wide application in both research and industrial fields.

According to official data, Yins Time Robot sold over 1,000 units of its five-fingered dexterous hand in 2023, nearly 2,000 units in 2024, and over 4,000 units in the first half of this year.

Lingxin Qiaoshou competes with “high freedom + low price.” Their LinkerHand product line covers various transmission methods including link, cable-driven, and direct drive. The L10, L20, and L30 models all have over 20 degrees of freedom but are significantly cheaper than foreign products — priced at 19,999 RMB and 49,999 RMB respectively.

According to co-founder and Chief AI Architect Su Yang, Lingxin Qiaoshou’s monthly sales exceed 1,000 units, capturing over 80% of the Chinese market and nearly 50% globally.

“Body Manufacturers” Developing Their Own Hands

Companies like DeepRobotics and Unitree focus on developing complete humanoid robots and design dexterous hands as integral components.

In mid-August, DeepRobotics released its OmniHand2025 series, including an interactive “Agile Version” with 16 degrees of freedom priced at 14,800 RMB and a professional version with 19 degrees of freedom.

Unitree’s Dex5-1P uses gear transmission, has 20 degrees of freedom, and achieves high load capacity — 3.5kg vertically and 4.5kg horizontally.

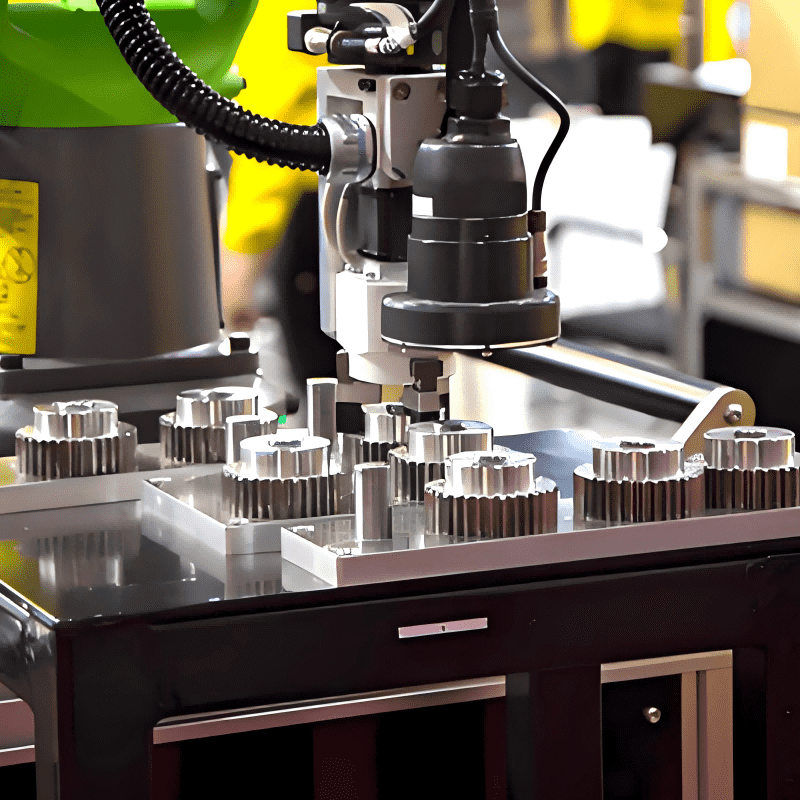

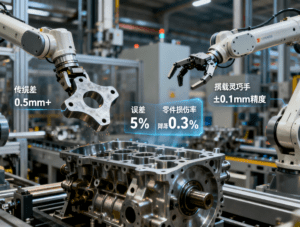

Notably, domestic dexterous hands have empowered industrial applications, such as providing core gripping solutions for Robotic Irregular-Shaped Metal Part Removal Systems used in automotive transmission gears and aerospace components. Systems equipped with Lingxin Qiaoshou’s L30 (25 DOF) or DeepRobotics’ OmniHand2025 professional version (19 DOF) can adjust gripping posture in real-time, reducing positioning errors to within ±0.1mm and part damage rate to below 0.3%.

Cross-industry Players

Companies like RoboSense, Zhaowei Electromechanical, and Leadshine Technology have leveraged their expertise from other fields to enter the dexterous hand market.

RoboSense, a leader in lidar technology, launched its first dexterous hand in 2024 and released the second generation Papert2.0 earlier this year, featuring 20 degrees of freedom, 15 sets of force sensors, and 5kg load capacity.

Trends: Increasing Freedom, Decreasing Costs

Domestic dexterous hands are showing two clear trends: continuously increasing degrees of freedom and rapidly decreasing costs.

In terms of freedom, products have evolved from about 6 degrees of freedom initially to 12-20 currently, approaching the 21-27 degrees of freedom of human hands.

In terms of cost, domestic products are significantly cheaper than foreign alternatives that often cost hundreds of thousands of dollars. As technology matures and the industrial chain improves, costs are expected to drop further.

Lingqiao Intelligent’s founder and CEO Zhou Chen stated that high-freedom dexterous hands could cost around 10,000 RMB within 2-3 years. Lingxin Qiaoshou’s Su Yang even claimed prices could drop below 500 RMB within three years, possibly within a year.

The Mass Production Challenge

Tesla CEO Elon Musk admitted that developing dexterous hands might account for half the difficulty of creating the entire Optimus robot.

The challenge lies in creating an industrial-grade, highly versatile dexterous hand that integrates precision machinery, force control algorithms, and multimodal sensing while balancing flexibility, load capacity, and cost.

Increasing degrees of freedom brings higher costs, more potential failure points, and increased weight — all affecting performance. The choice between load capacity and flexibility depends on specific applications: industrial handling requires strength while medical surgery demands agility.

Similarly, there’s no consensus on whether three-fingered or five-fingered designs are optimal. Three-fingered hands are simpler and more reliable for industrial applications, while five-fingered designs offer greater versatility for complex environments.

The Future: Lighter, More Flexible, More Intelligent

As the humanoid robot industry accelerates, dexterous hand development is converging toward making them lighter, more flexible, and more intelligent — advancing from simply “being able to grasp” to “being able to grasp precisely.”

Lightweight design is crucial for reducing inertia, increasing response speed, and lowering energy consumption. Current products generally weigh under 1kg, with some as light as 400g.

For example, BrainCo’s Revo2 is similar in size to a human female hand but weighs only 383g while achieving a grip force of 50N and load capacity of 20kg. Lingxin Qiaoshou’s LinkerHandO6 weighs 370g yet can handle over 30kg.

Materials like magnesium alloys, carbon fiber composites, engineering plastics, and especially PEEK are becoming important for lightweight design.

Higher degrees of freedom are enabling more precise operations, with leading products reaching 20+ degrees of freedom. Transmission systems are evolving from simple tendon or link designs toward hybrid solutions like Tesla’s innovative “lead screw + tendon” approach.

Sensing capabilities are advancing from basic force detection to multimodal perception with tactile sensors becoming standard. The trend is toward “electronic skin” covering the entire hand, providing detailed information about object shape, texture, hardness, and temperature.

Conclusion

The dexterous hand industry is making the crucial leap from technological breakthrough to commercial validation. Chinese companies, with their dual advantages of high freedom and low cost, are rapidly gaining ground in global competition.

Future competition will focus not on who has the most degrees of freedom or highest load capacity, but on who best adapts to specific scenarios: stability and cost control for industrial applications, safety and versatility for household services, and precision and force control for medical procedures.

When dexterous hands with 20+ degrees of freedom can be produced for around 10,000 RMB and can perform tasks like picking up potato chips without breaking them or holding a power drill securely, they will truly complete the final piece of the humanoid robot puzzle.

One day, we may take for granted robots that can hand us objects, do housework, or even assist in surgery. And we’ll remember that this revolution began when Chinese innovators opened the door to industrialization with affordable, high-performance dexterous hands.

Robots realize the automated assembly of automotive connectors