Table of Contents

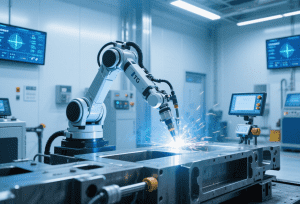

ToggleRobotic TIG Welding Steps Toward Full Automation in the Era of Intelligent Industrial Automation

In the ever – evolving landscape of industrial automation, where intelligent automation technologies are revolutionizing manufacturing processes, robotic TIG welding is emerging as a game – changer. While automation has the potential to streamline almost any manufacturing task, achieving seamless operation, especially in specialized TIG welding operations, remains a complex challenge. This is precisely why M&M Industrial Services, an oil and gas industry service provider based in Beaumont, Texas, was elated when it received the first test unit of Novarc Technologies’ SWR – TIPTIG cobot. The company quickly discovered how this advanced automation equipment could enhance the reliability of its mission – critical welding tasks.

Automating a Tricky Task

The SWR – TIPTIG system is meticulously designed to meet the demands of the daily operations at M&M, which often involve working with stainless pipes. Operations Manager Daniel Metreyeon described M&M as “a 9 – 1 – 1 shop of everything” for the oil and gas industry. Beyond pipe work, the welding system is also well – suited for pressure vessels and roll welding applications, particularly when dealing with high – strength materials such as carbon steel, duplex, super duplex, INCONEL alloy, titanium, and stainless steel. M&M utilizes 4130 grades in its TIG weld process for subsea and well – control piping in the oil and gas industry.

When Novarc initiated concept work on the welding system in 2021 and 2022, the primary focus was on providing a solution for shipbuilding, specifically for copper – nickel pipes. As Novarc CEO Soroush Karimzadeh explained, copper – nickel used in saltwater piping systems in shipbuilding is extremely challenging to weld with MIG processes and is often best welded with TIG. Similarly, many specialty stainless steel materials used in aerospace and other industries pose significant welding difficulties.

For Metreyeon, the physical properties of the materials M&M welds, combined with tight deadlines, demanded a process that could outperform manual TIG and MIG welding in terms of speed and efficiency. The company’s fabrications frequently include high – pressure pipes rated up to 20,000 PSI, which is why M&M agreed to be the alpha tester for the SWR – TIPTIG system. “We actually had a prototype that got here in January 2024,” Metreyeon said. “We worked closely with our welding engineers and Novarc to develop the procedures and the weld recipes. There are 13 combinations of pipe grades that we’ve helped develop weld recipes for, which includes stainless, carbon steel, and all the high – strength grades. We agreed to enter this arrangement to help improve production. Our line of work involves a lot of TIG in our high – pressure fabrication. These systems include up to 20K and 15K piping here. This helps provide alternative options to the MIG process for high – strength applications.”

However, even with the advanced capabilities of the SWR – TIPTIG cobot, full automation remains a goal rather than a reality. This is especially true when welding 2 – inch – thick pipes with a 3.5 – inch weld gap, which are common in M&M’s operations. In such cases, welding operators play a crucial role in preventing weld flaws and slag inclusion in the root and fill passes, which could compromise the integrity of the weld. Metreyeon also noted that although M&M has fulfilled multiple orders using the two units it has, many of the piping configurations between January and now are not ideally suited for the 1G roll out that the machine is designed for. Nevertheless, the company’s project team maximizes the use of this automation equipment to increase the weld deposition rate as much as possible. “Basically, we try to plan our fabrication out so that anytime you can use the robot in the controlled environment, you’re light years ahead in making that weld,” Metereyeon said. “The value is consistency. You have human error. They’re taking breaks, and they’ll run the wire for a minute and then get a cramp in their hand. They shut down and then fire back up. This machine is consistent. It’s constantly moving, constantly rolling. Once you hit go, you’re just driving it. The consistency there, the amperage, the travel speed—everything is set.”

Filling Other Gaps

According to Karimzadeh, the ability to use automation to handle tight – tolerance work with less – experienced operators, rather than relying solely on highly skilled welders, makes cobots like the SWR – TIPTIG an attractive option for shops of all sizes. “There is a big shortage of welders. To any degree that we can free up human welders to do the more difficult welds, that’s an overall win,” Karimzadeh said. “This technology helps human welders, TIG welders, become much more productive. It’s not necessarily the number of passes, because that’s kind of driven by the material and the weld speed and the weld quality requirements—but we do weld faster compared to, say, manual TIG, for sure, using TIPTIG technology. There’s an upper limit to speed, but because hands are not doing it repeatedly for hours and hours in a day, we can break that productivity ceiling and get to higher – diameter inches than would otherwise be possible.”

For Metreyeon and M&M, the adoption of robotic TIG welding is not only about handling challenging materials but also about maintaining the company’s reputation for delivering exceptional service to its customers. “If the customer calls us and needs something special, then we are always up to the challenge,” Metreyeon said. “We are a service provider who generally does not turn down work, and we specialize in specialty fabrication with tight deadlines. Most of the clients that we work very closely with typically reach out for advice beforehand to help streamline engineering and fabrication deadlines.”

As the industrial automation sector continues to embrace intelligent automation, robotic TIG welding systems like the SWR – TIPTIG are not just tools; they are integral components driving the transformation of manufacturing. By bridging the gap between skilled labor shortages and high – demand production, these automation equipment solutions are setting new standards for efficiency, quality, and reliability. The journey toward full automation in TIG welding is well underway, and its impact on the future of industrial manufacturing is bound to be profound, reshaping the industry one precise weld at a time.