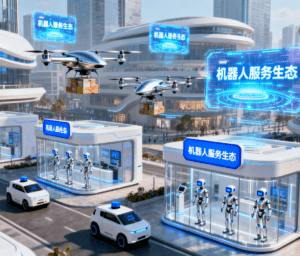

Not long ago, the scenario of an embodied intelligent robot—capable of walking, operating tools, and communicating—integrating into daily life was exclusive to science fiction works. Today, as robot experience stores open “like bamboo shoots after rain” across the country, this scene seems to be accelerating its transition from the screen to reality.

Global’s First Robot 4S Store Opens

On August 8, 2025, the world’s first robot 4S store officially opened. The biggest difference from an automotive 4S store is that this is not a display space for a single brand, but an aggregation area for robots. By creating an integrated model of “scenario experience—on-the-spot sales—service delivery”, it paints a future picture for customers of how robot technology can integrate into people’s daily lives from laboratories and factories.

In the 4S store, visitors can engage in interactive experiences at counters featuring dexterous robot hands, brain-computer interfaces, visual systems, robotic arms, robot dogs, competitive robots, educational robots, and humanoid simulation robots. This allows them to experience the charm of robots to a great extent.

For the entire robot industry, the model of this 4S store holds milestone significance—it builds a bridge connecting enterprises and consumers. It brings intelligent robots from laboratories and factories into the sight of consumers, enables the direct collection of feedback from the market frontline, drives product iteration and optimization in a reverse manner, and accelerates the transformation of technology into practical value.

Yangtze River Delta Robot 6S Flagship Store Launched

On November 8, at the 2025 Automotive Technology and Equipment Development Forum themed “Automotive Industry Embraces Artificial Intelligence”—co-hosted by the Ministry of Industry and Information Technology and the Suzhou Municipal Government—the “Yangtze River Delta Robot 6S Flagship Store” was officially launched. Located in the Integrated Circuit Innovation Center of Shishan Cultural Square in Suzhou High-tech Zone, the flagship store adopts an innovative “front-store, back-park” model. It is committed to connecting the entire chain of robots from technological R&D to market application, injecting strong impetus into fostering new-quality productive forces and promoting the intelligent upgrading of manufacturing.

The most innovative feature of this flagship store lies in its “front-store, back-park” operation model:

Front-store: Refers to the 6S flagship store itself, which faces the market and customers directly, undertaking functions such as product launches, scenario verification, and market transformation.

Back-park: Refers to the Taihu Embodied Intelligence Industrial Park. As the industrial support behind the store, it focuses on the R&D, pilot testing, and manufacturing of key technologies such as human-computer interaction and autonomous decision-making.

This model aims to deepen the layout of the embodied intelligence industry, bridge the “last mile” from laboratory technology to market application, and improve the collaborative efficiency of the industrial chain. Currently, the flagship store has taken the lead in establishing an embodied intelligent robot training center.

China’s First Humanoid Robot 7S Store Opens in Wuhan Optics Valley

On November 11, China’s first humanoid robot 7S store opened in Wuhan Optics Valley. It is not only a sales outlet but also a bridge connecting laboratory technology with customer needs, enabling humanoid robots to enter the mass consumer market just like automobiles.

Compared with the “4S” of automobiles, the “7S” of humanoid robots covers seven functions: Sale, Spare parts, Service, Survey, Solution, Show, and School.

Among these, the store’s core function—complete machine sales—breaks through the traditional commodity sales model by adopting scenario-based experiential sales. It covers more than ten robot application scenarios, including industrial manufacturing, cultural tourism guidance, elderly care, and special operations. Notably, the industrial manufacturing zone showcases syringe automatic assembly equipment integrated with robotic vision and precision motion control technology, allowing medical industry customers to intuitively experience the high-efficiency and high-precision assembly capabilities of intelligent robots in medical device production. This high-value, high-tech solution-based sales approach allows customers to experience the charm of robots in an immersive way, persuading them to make purchases.

The spare parts area displays dedicated modules and vulnerable components of robots, such as chips and dexterous hands—all core parts sourced from the local industrial chain in Hubei Province.

By establishing a standardized sales and service system, this 7S model solves the problems of delayed services and high usage thresholds, marking a key step in promoting the humanoid robot industry to move from laboratories to commercial districts. In the future, it will continue to deepen the development path of “platform leadership, scenario-driven, and ecological collaboration”, helping Wuhan Optics Valley build a demonstration highland for humanoid robot applications.

Conclusion

In the second half of 2025, the successive openings of robot 4S stores, 6S flagship stores, and humanoid robot 7S stores demonstrate the trend of robots gradually moving from laboratories to the mass market. Through models such as immersive scenario experiences and complete machine sales, robots are no longer just “workers” in factories, but can also become intelligent partners in people’s lives and work. As a pioneer position in this transformation, experience stores have built a closed loop where market feedback directly reaches R&D, bridged the “last mile” from technology to application, driven industrial chain agglomeration through end-consumption, and will reversely promote product iteration and industrial upgrading—injecting strong impetus into the cultivation of new-quality productive forces.

What is the work done using automated equipment and machines called?