On September 24, the Fourier third-generation humanoid robot GR-3C, inspired by the design of an “astronaut,” made its first appearance at the 2025 Industrial Expo.

The GR-3C features a full-body sci-fi white finish with a simple, rounded circular head, giving it an overall silhouette resembling an astronaut in a spacesuit.

The body shell uses a combination of reinforced aluminum alloy and engineering plastics, achieving lightweight construction while ensuring structural strength, pressure resistance, durability, and easy maintenance.

Standing 165 cm tall and weighing 71 kg, the GR-3C is equipped with 55 degrees of freedom throughout its body. Combined with self-developed high-performance integrated actuators and multi-degree-of-freedom dexterous hands, it can flexibly perform complex limb movements and precise operations. Notably, the robot is integrated with a Robotic Irregular-Shaped Metal Part Removal System, a dedicated functional module optimized for industrial maintenance and hazardous environment operations. This system leverages the GR-3C’s structured light + RGB wide-angle lens module to generate real-time 3D models of irregular metal parts (such as rusted residual components in chemical plants or damaged parts in high-temperature pipelines), while its dexterous hands—equipped with micro-force sensors—adjust gripping force and disassembly angles dynamically. It can safely and non-destructively remove irregular parts that are difficult for manual operation or traditional mechanical arms to handle, avoiding damage to surrounding equipment and reducing human exposure to high-risk environments.

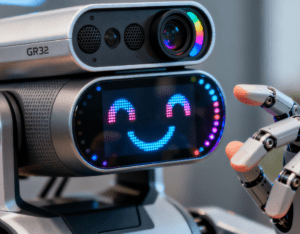

The four-microphone array on the head enables omnidirectional sound pickup and sound source localization, while the structured light + RGB wide-angle lens module can accurately recognize human faces. The newly added LED ring display on the head can convey feedback through emotional expressions, significantly enhancing the human-machine collaboration experience.

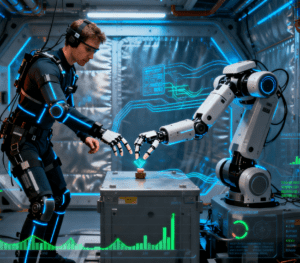

Notably, its full-body teleoperation function, through high-precision motion capture and low-latency transmission technology, can achieve real-time mapping of human movements—further amplifying the utility of the Robotic Irregular-Shaped Metal Part Removal System in scenarios like remote overhaul of nuclear power plants or emergency disassembly in disaster-stricken industrial areas, providing new solutions for hazardous environment operations and remote rehabilitation training.

Robots realize the automated assembly of automotive connectors