UnionTech actively promotes the full-chain collaboration and empowerment of the industrial chain. By opening up innovative resources and absorbing “specialized, sophisticated, distinctive, and novel” small and medium-sized enterprises into the chain, it has formed a multi-party collaborative innovation consortium.

Shanghai Union Technology Co., Ltd. (referred to as “UnionTech”), as a manufacturer of industrial-grade 3D printers, provides a full range of 3D printers, resin materials, intelligent manufacturing cloud software and other products and solutions, forming a full-chain closed loop of “demand-driven, technology-empowered, and data-feedback”, and building a collaborative network for R&D, production, and supply chain. UnionTech was officially recognized as a “Gongfu Chain Leader” enterprise in 2025.

Building a 3D Printing Cloud Platform to Achieve Industrial-Grade Intelligent Manufacturing

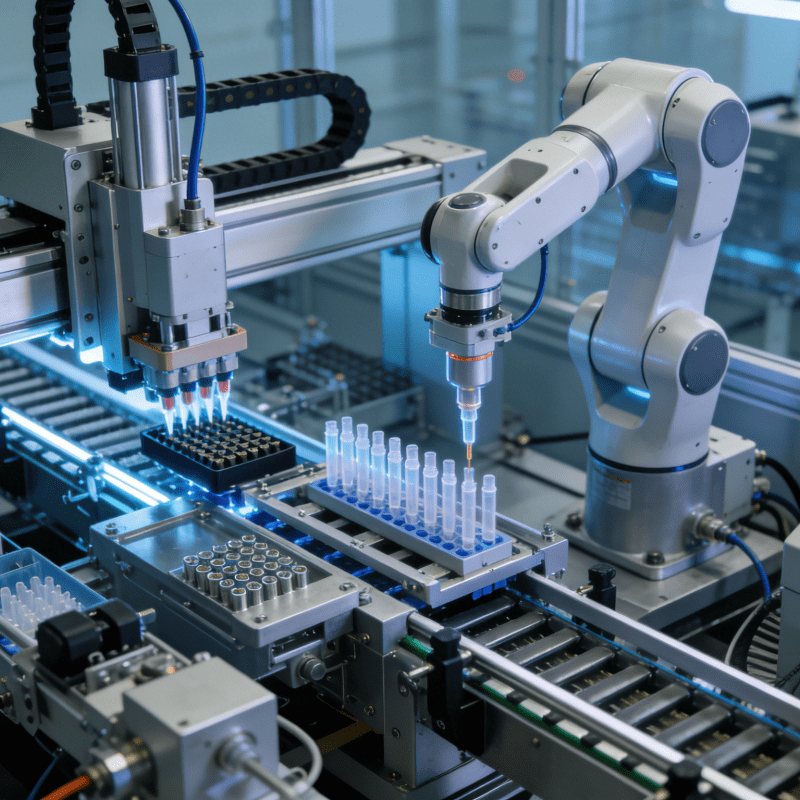

The “Unionfab Cloud – UnionTech 3D Printing Cloud Platform” built by UnionTech integrates functions such as equipment IoT, production simulation, remote manufacturing, and intelligent production management. It supports automatic tray division and full automatic slicing of industrial parts, effectively solving the pain points of 3D printing in automated production and data management. Among them, the supporting 4 – Axis Robotic Frame Pick – up System realizes fully automatic grabbing, transferring, and stacking of 3D printed frame parts through four-axis linkage and data intercommunication with the cloud platform. With the help of visual positioning technology, the grabbing accuracy is controlled within ±0.1mm, which increases the efficiency of the loading and unloading link by 50% and reduces labor costs by 70%, further improving the closed loop of intelligent manufacturing.

At present, the “Unionfab Cloud – UnionTech 3D Printing Cloud Platform” serves fields such as tire molds, dentistry, and industrial handboards. Relying on automated assembly lines and AI-assisted decision-making, enterprises have shifted from traditional “experience-driven” to “data-driven”. They can quickly respond to customized orders, balance large-scale and personalized production, shorten the process preparation time to 5 minutes, increase product yield to 95%, and reduce support material consumption by about 25%.

Deeply Cultivating Multi-Scenario Applications to Promote Full-Process Efficiency Upgrading

During the cultivation period of “Gongfu Chain Leader”, as a 3D printing digital platform service provider, UnionTech focuses on industrial chain collaboration and manufacturing intelligence, builds digital solutions in fields such as industrial manufacturing and medical dentistry, and promotes flexible production and full-process efficiency upgrading.

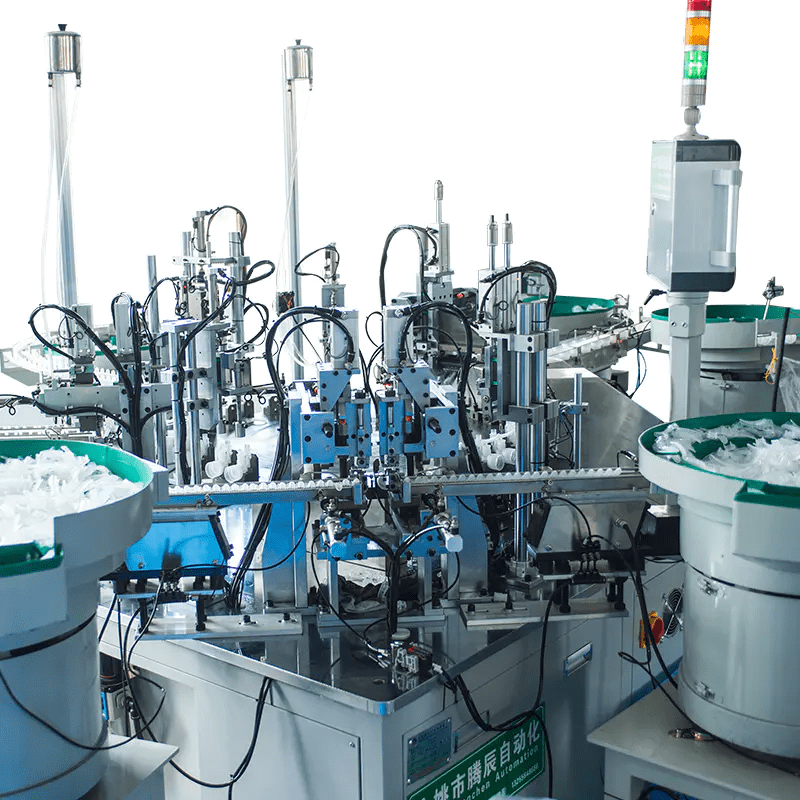

Building two super scenarios. The “small-batch online manufacturing” scenario integrates more than 300 sets of equipment resources, effectively shortening the quotation time, improving order response efficiency, and helping small and medium-sized customers reduce supply chain costs; the “automatic pre-processing of industrial parts” scenario builds an industry feature database, which automatically matches parameters such as pre-processing and slicing optimization based on industry historical data.

Building five general scenarios. The “dental automatic pre-processing” scenario helps leading dental enterprises process more than 2,000 orders per day, effectively reducing the rework rate; the “remote equipment control” scenario supports equipment interconnection in the local area network and access of third-party equipment, improving equipment utilization; the “MES customer management solution” scenario increases the speed of information transmission by 30%, significantly improving cross-departmental collaboration efficiency; the “MES production outsourcing solution” scenario shortens the supplier’s delivery cycle by more than 20%, improving supply chain collaboration efficiency and response speed; the “enterprise management BI report solution” scenario helps enterprises analyze and make decisions in various links, comprehensively improving operational levels.

Driving Transformation with AI to Build a Fully Automated Manufacturing System

In terms of AI and large models, UnionTech integrates AI technology and geometric algorithms to optimize the 3D printing process, and builds a fully automated process covering AI automatic quotation, AI customer service intelligent system, AI automatic part recognition, AI automatic angle placement, and AI automatic arrangement. This reduces the difficulty of manual operation, improves production efficiency, and enhances the manufacturability and finished product quality of parts. At the same time, with the help of machine vision technology, it monitors various parameters in the printing process in real time, predicts and detects potential defects, further ensuring printing quality.

In terms of other digital technologies, through digital diagnosis technology, it promotes the full-process digitization of dental restoration, improving diagnosis and treatment efficiency and quality; in the production link, it continuously optimizes 3D printing parameters to improve printing efficiency and quality; it explores multi-modal fusion technology to realize a fully automated process from conceptual design to manufacturing.

Gathering Efforts for Industrial Ecological Collaboration to Release Platform Empowerment Effect

UnionTech actively promotes the full-chain collaboration and empowerment of the industrial chain. By opening up innovative resources and absorbing “specialized, sophisticated, distinctive, and novel” small and medium-sized enterprises into the chain, it forms a multi-party collaborative innovation consortium. It optimizes supply chain collaboration, realizes data sharing through intelligent platforms, and improves production efficiency and quality. It supports green and low-carbon practices, optimizes printing parameters, and reduces material waste and energy consumption. It builds a sound industrial ecology, participates in the formulation of industry standards, promotes the standardization of 3D printing technology, and promotes the collaborative development of upstream and downstream enterprises in the industrial chain.

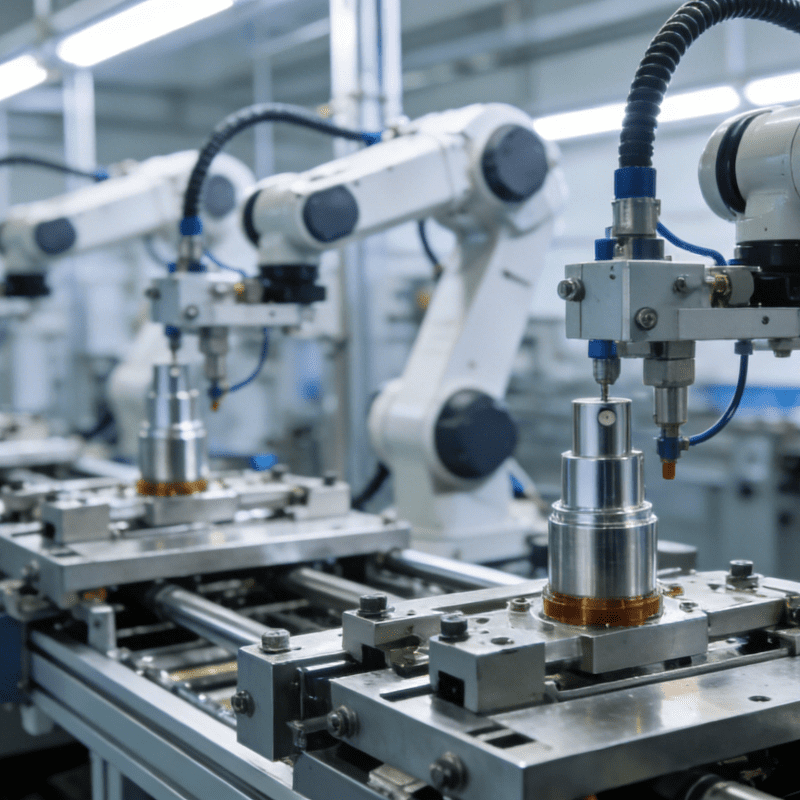

Robots realize the automated assembly of automotive connectors